A complex special-shaped multi-position laser marking equipment

A laser marking equipment, multi-position technology, applied in the field of laser marking, can solve the problems of high risk, high difficulty in operation, limited application scope of marking equipment, etc., to avoid congestion and blockage, improve efficiency, and shorten the cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

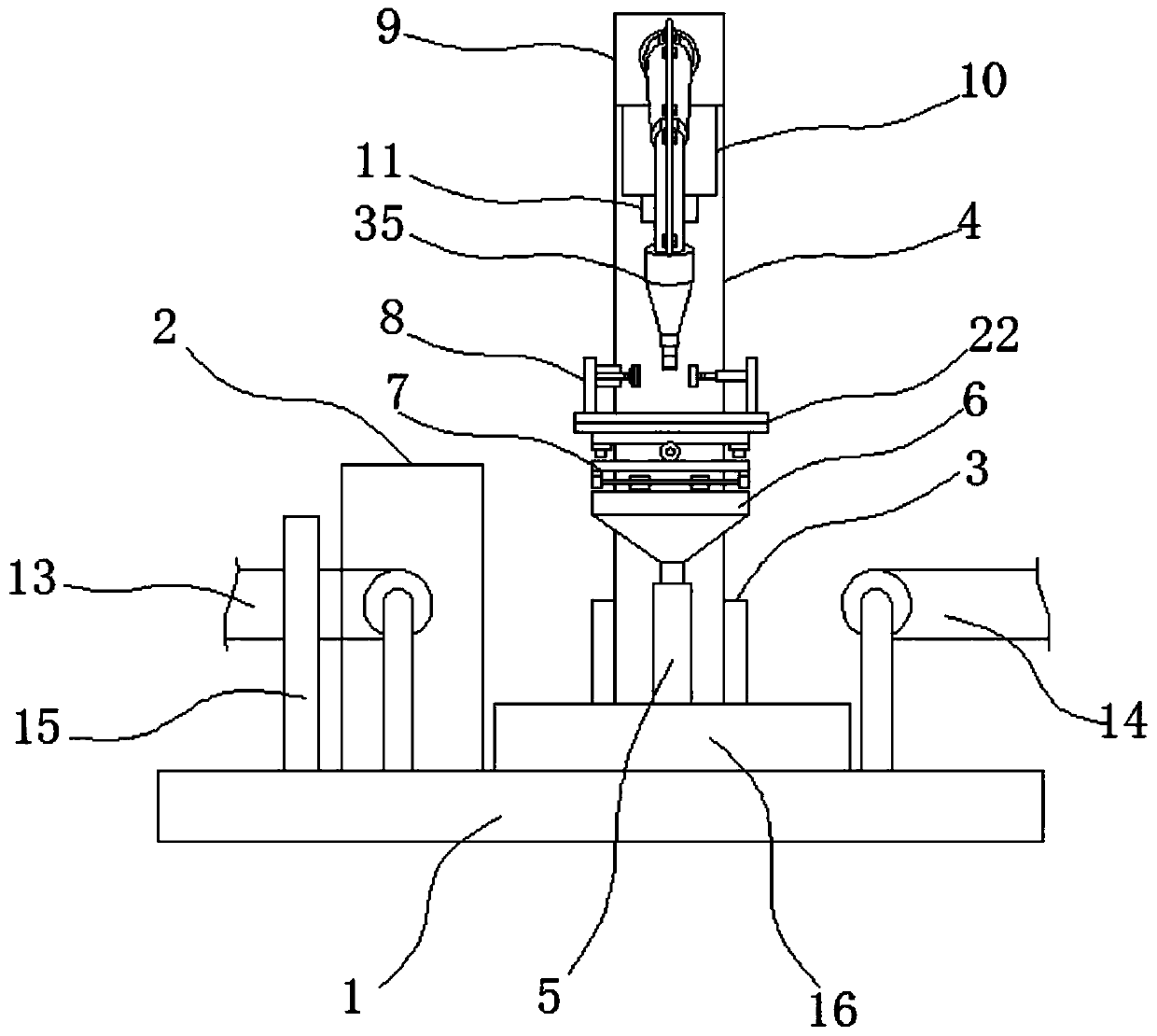

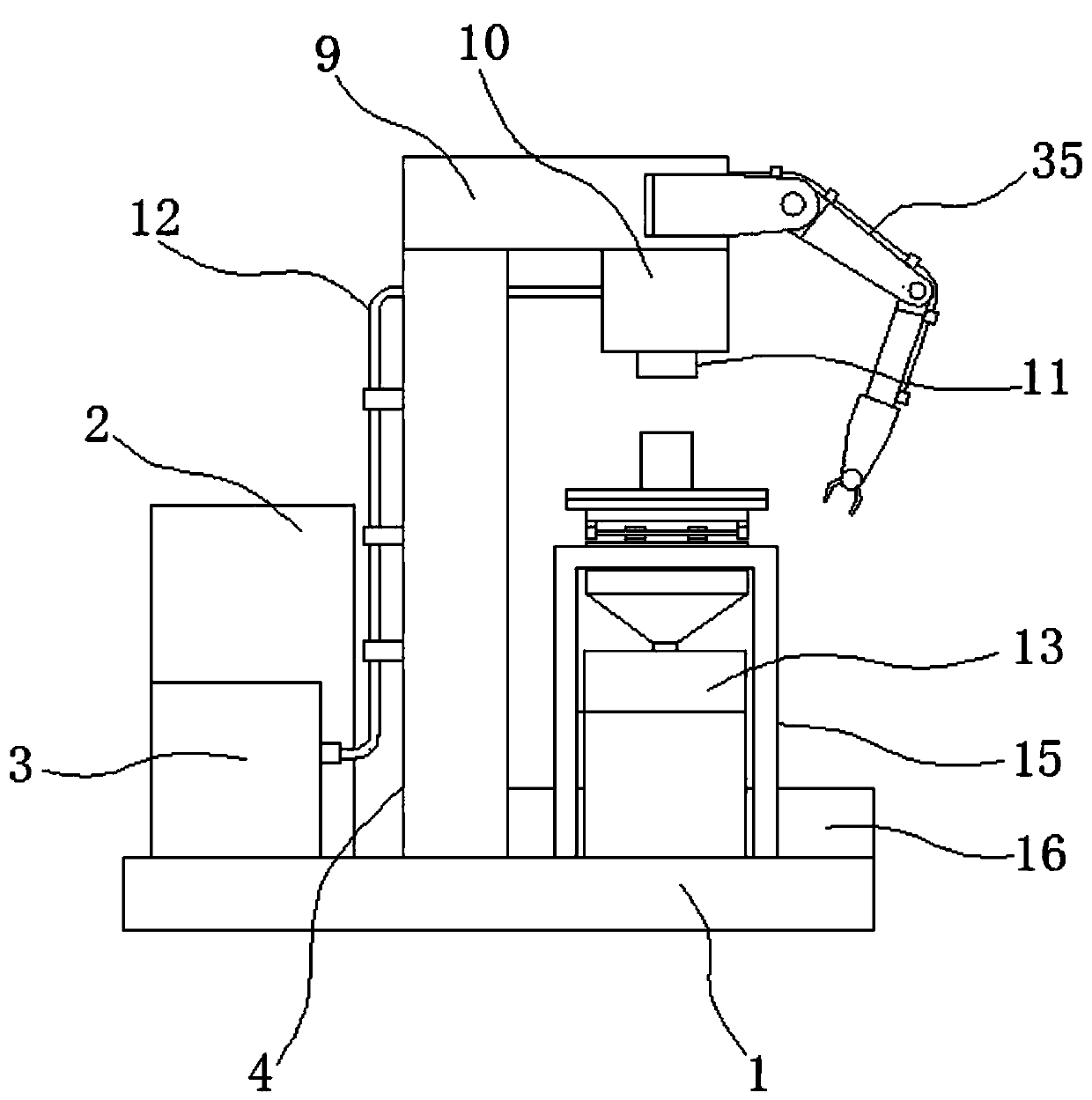

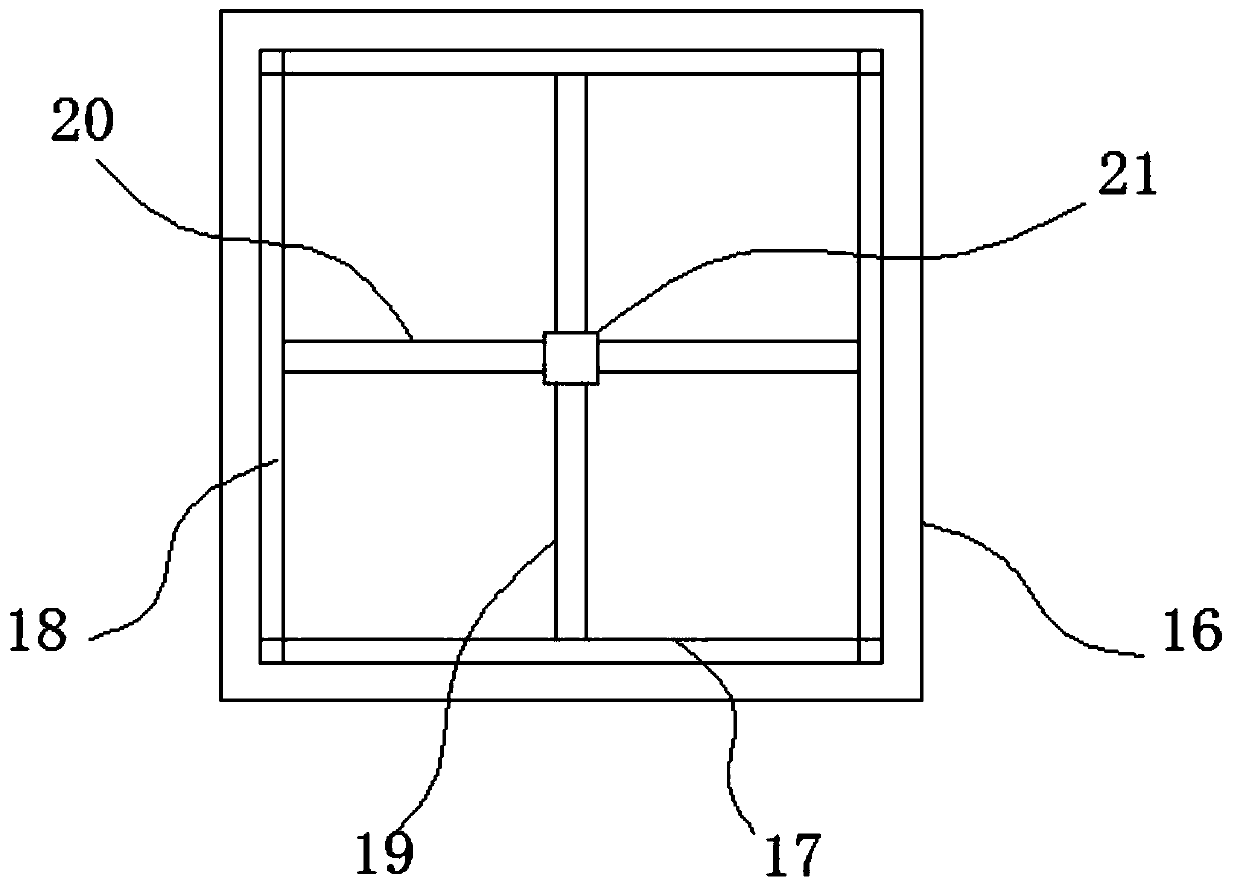

[0028] like Figure 1-5 As shown, a complex special-shaped multi-position laser marking equipment includes a base 1, a control host 2, an optical fiber marking machine host 3 and a column 4 are arranged on the base 1, a translation mechanism is also provided on the base 1, and the upper end of the translation mechanism Connected with a jacking mechanism 5, the upper end of the jacking mechanism 5 is connected with a mounting base 6, the upper end of the mounting base 6 is equipped with a three-dimensional workbench 7, and the operation table of the three-dimensional workbench 7 is provided with a workpiece fixing mechanism 8; the upper end of the column 4 is connected There is a beam 9, the front end of the beam 9 is connected with a six-axis manipulator 35, the six-axis manipulator 35 is electrically connected with the control host 2, the lower side of the front end of the beam 9 is connected with a vibrating mirror 10, and the lower end of the vibrating mirror 10 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com