Backlight drive circuit

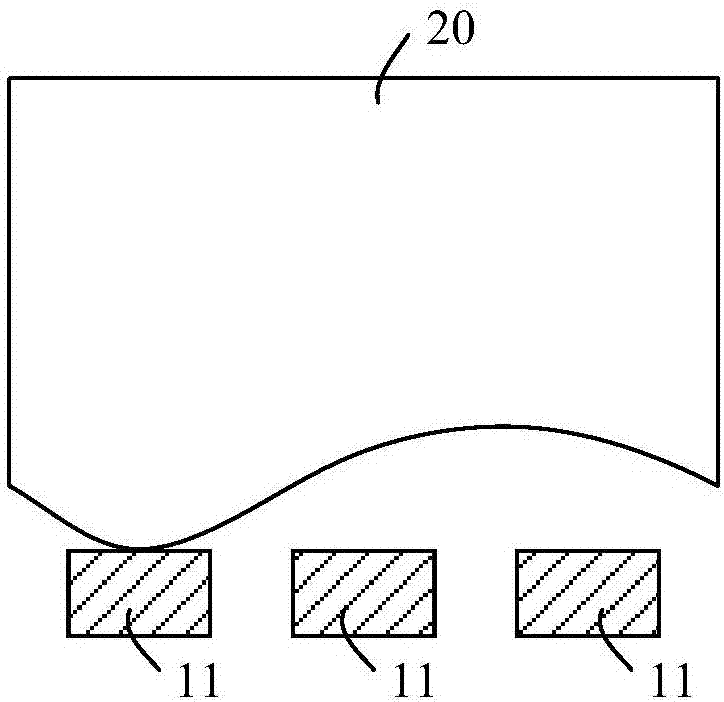

A technology of backlight drive circuit and comparison circuit, which is applied to instruments, static indicators, etc., and can solve problems such as deformation damage, reflection sheet or light guide plate deformation damage, high operating temperature of liquid crystal display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

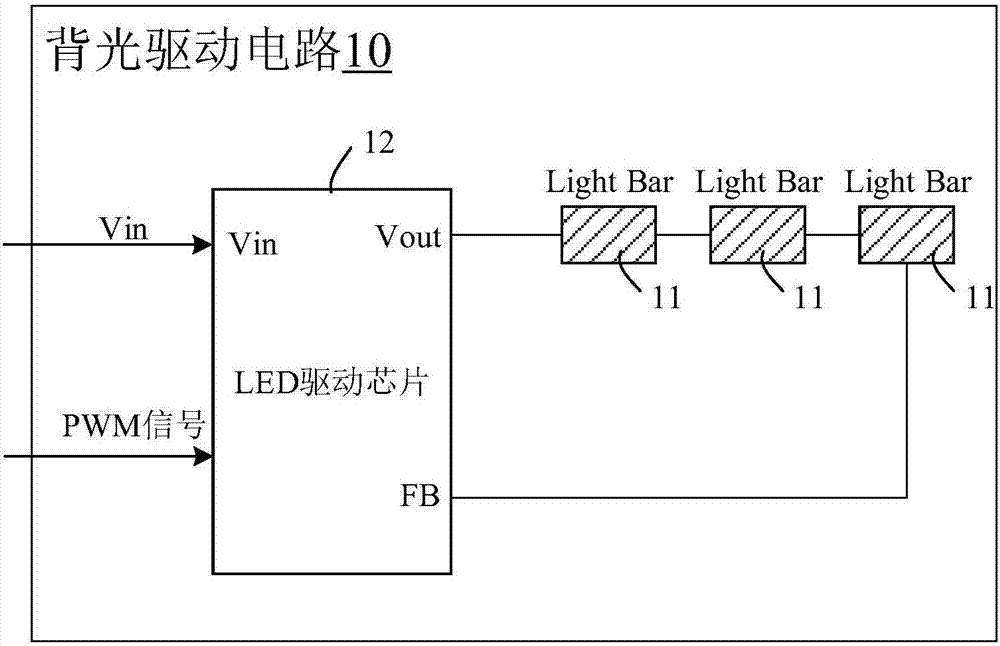

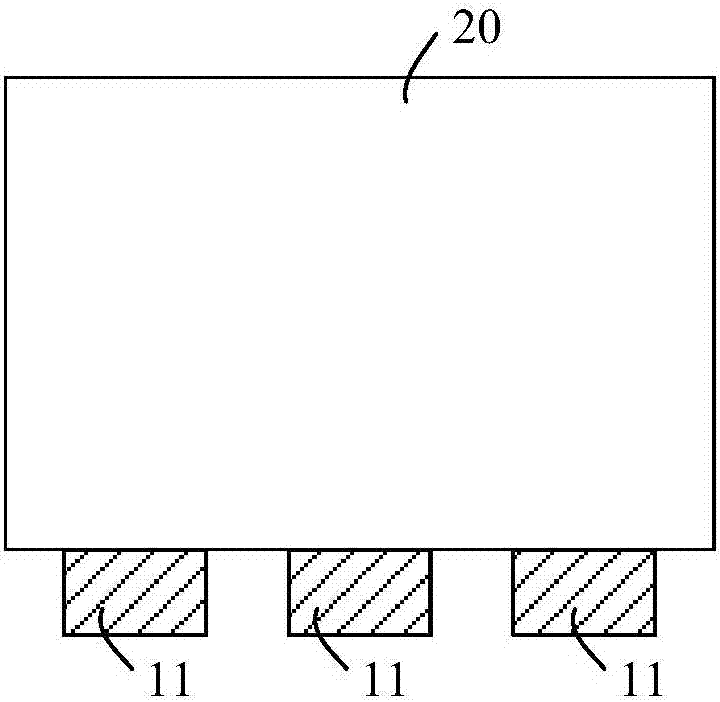

[0027] image 3 A circuit diagram of a backlight driving circuit provided according to an embodiment of the present invention is shown. Such as image 3 As shown, the backlight drive circuit 10 includes an LED light bar 11 , an LED drive chip 12 , a temperature detection circuit 13 , a comparison circuit 14 and a reference current generation circuit 15 .

[0028] Wherein, the LED driving chip 12 is used for outputting backlight current to drive the LED light bar 11 .

[0029] In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com