Double-end punching automatic peeling machine for Gorgon fruits

A technology of chicken head rice and peeling machine, which is applied in the direction of punching machine, press machine, peeling of vegetables or fruits, etc., can solve the problems of high manufacturing cost, unfavorable improvement of production efficiency, large-scale popularization and application, and high failure rate. Achieve the effect of simplified structure design, wide size range and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

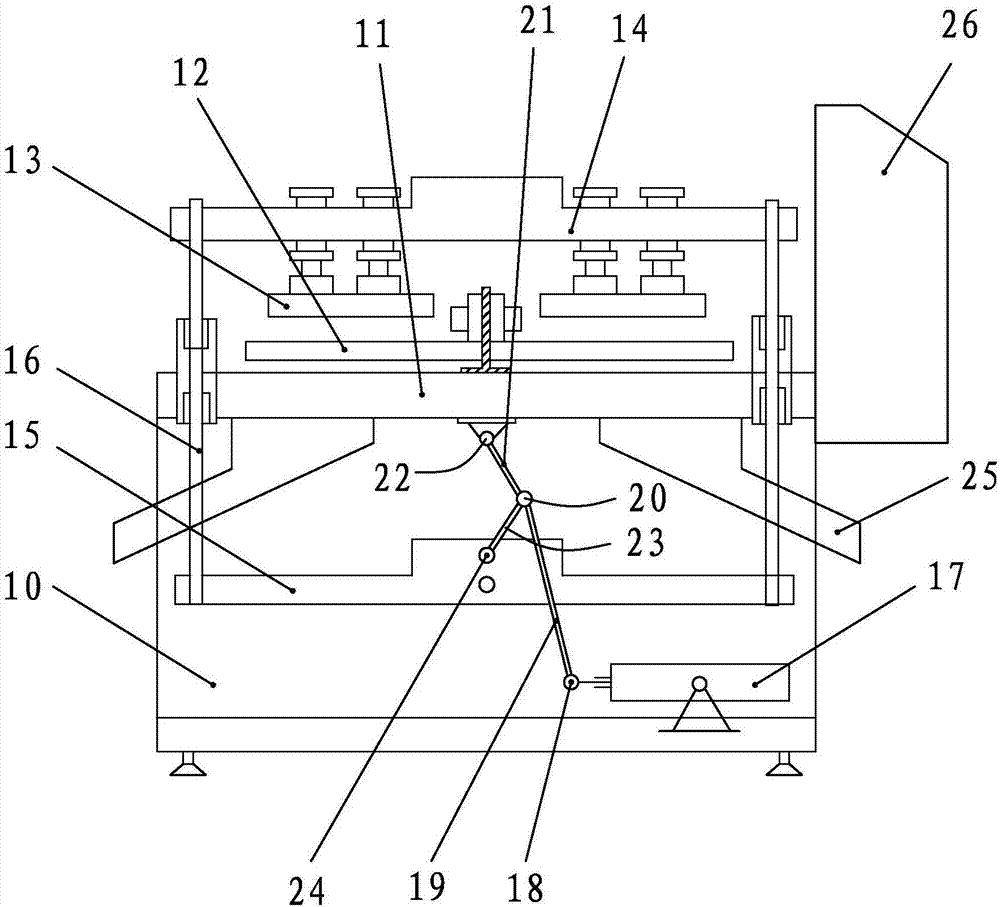

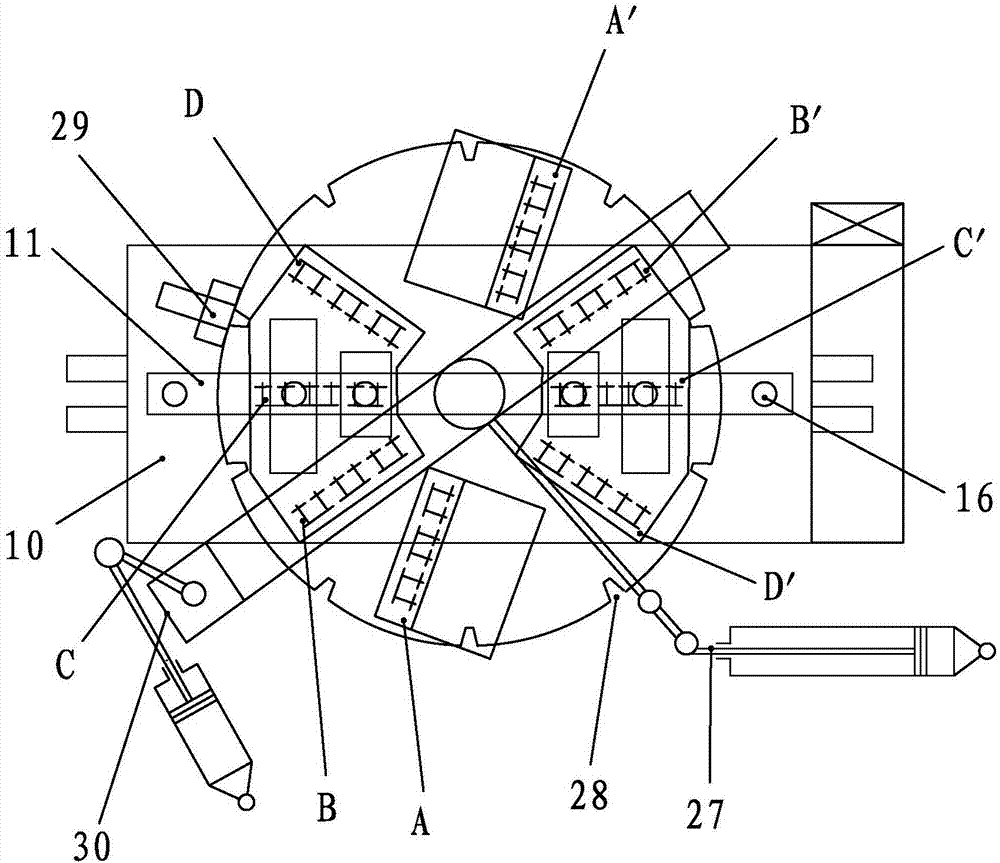

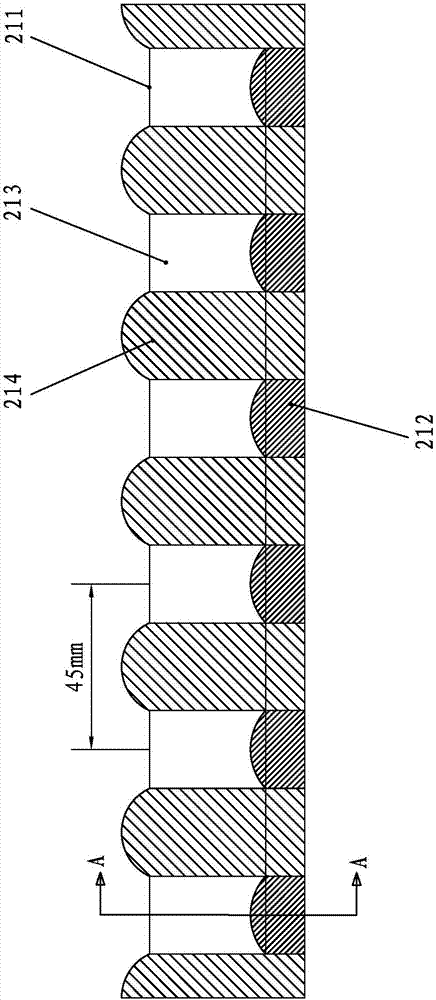

[0055] refer to figure 1 and 2 , the double-head stamping chicken head rice automatic peeling machine provided by the present invention includes: a frame 10, a support beam 11 arranged on the top of the frame 10, a rotating disk 12 installed on the support beam 11 by a rotating shaft and an indexing cylinder 27, And the stamping head 13 located above the turntable 12 and corresponding to the turntable 12; the turntable 12 sequentially includes two symmetrical feed stations A, A', two symmetrical bottom skin removal stations B, B', Two rice kernel stamping stations C, C' and two upper leather shell stamping stations D, D', the two rice kernel stamping stations correspond to the support beam 11 up and down and correspond to the upper lifting plate up and down, and the stamping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com