Pipe sleeve puller

A technology of puller and sleeve, which is applied in the field of machinery, can solve the problems of not being widely used, the extension arm is suspended in the air, and the pulling range of the puller is limited, so as to solve the problem of sliding or breaking of the pull claw and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

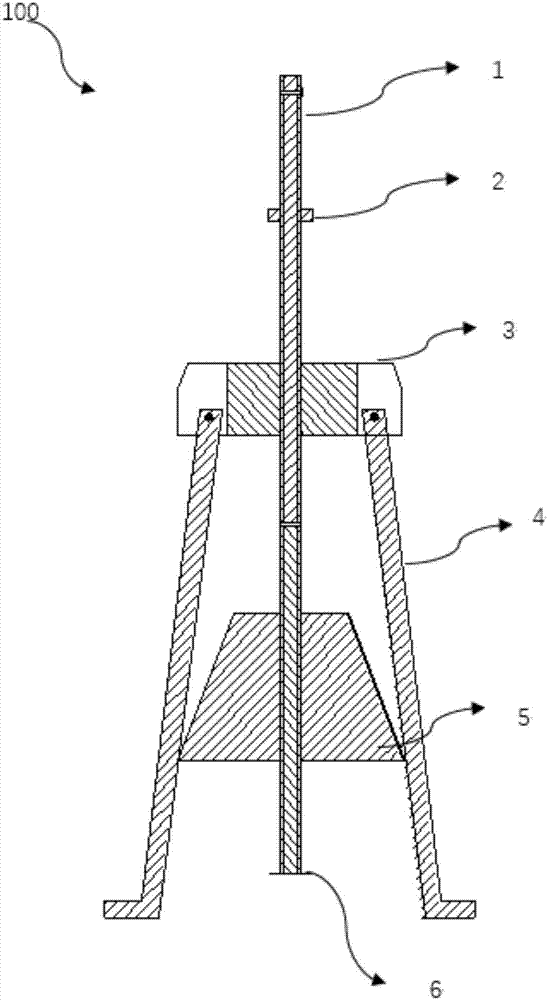

[0018] Such as figure 1 As shown, the longitudinal sectional view of the sleeve puller 100 includes: a screw 1 , a compression nut 2 , a claw seat 3 , a claw 4 , a conical expander 5 and a detachable baffle 6 .

[0019] One end of the screw 1 is a right-handed thread, the other end is a left-handed thread, and the center of the claw seat 3 is provided with a threaded through hole. Both ends of the screw 1 are threaded in different directions. When the screw 1 is turned, the conical expander 5 must be close to the claw seat 3 or away from the claw seat 3; more preferably, it can be connected between the screw 1 and the claw seat 3 The end is provided with a through hole, the center line of the through hole is perpendicular to the axis of the screw rod 1. This through hole is an operation hole, and an iron bar can be inserted in the through hole to facilitate the rotation of the screw rod 1; more preferably, the lower end of the screw rod 1 is installed A detachable baffle 6 is...

no. 2 example

[0025] The difference between the sleeve puller of the second embodiment of the present invention and the first embodiment is that the contact surface between the bent portion of the pull claw 4 and the sleeve is provided with knurling, and the knurling can be straight grain knurling or Knurled knurling; the side wall of the conical expander 5 is provided with guide rail grooves according to the number of pull claws 4, and the pull claws 4 slide and fit with the guide rail grooves.

[0026] When the pipe sleeve that needs to be pulled out is not a through hole, the puller can press the pull claw 4 on the inner wall of the pipe sleeve. The friction force between the claw 4 and the inner wall of the pipe sleeve is increased, and the sliding of the claw 4 is avoided when pulling out. More preferably, the knurling can be straight grain knurling or net knurling; the conical expander 5 is set There are guide rail grooves so that the pull claws are not easy to shake, and the conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com