Special milling clamp for machining breaker base U-shaped waist

A technology of circuit breakers and bases, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high production cost, long machine time, low scrap rate, etc., and achieves low manufacturing cost and reduced mobility. Time and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

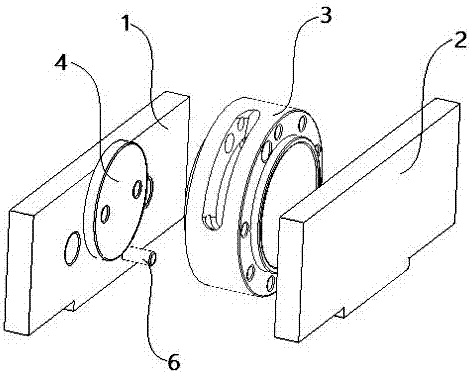

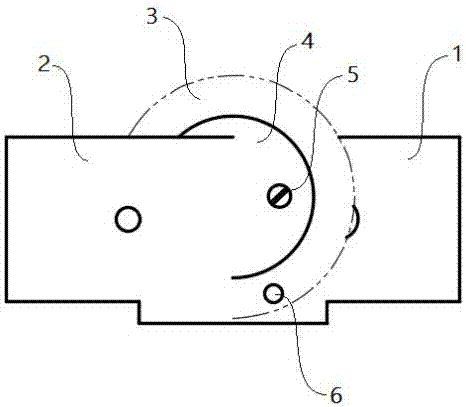

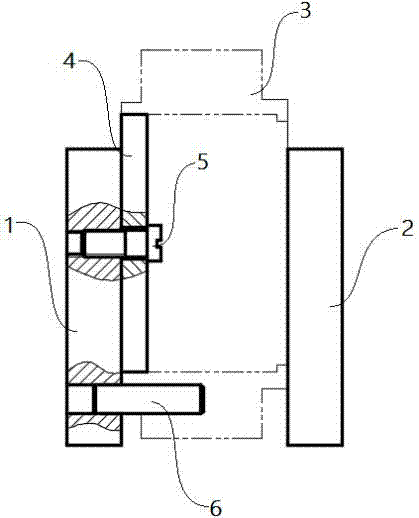

[0025] see Figure 1-3 As shown, a special milling fixture for processing the U-shaped waist of the circuit breaker base is composed of a positioning plate 1 installed on the fixed jaw of the vise and a movable plate 2 installed on the movable jaw of the vise; the positioning plate 1 The middle part of the side is provided with a positioning disc 4 for positioning the circuit breaker base 3, the positioning disc 4 is fixed on the positioning plate 1 by two slotted cylindrical head screws 5, and the positioning disc The upper part of 4 is higher than the upper end surface of the positioning plate 1; the lower part of the inner surface of the positioning plate 1 is provided with a short pin 6 for determining the U-shaped waist milling angle, and the short pin 6 is located on the positioning disc 4, and located on one side of the verti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap