Small paper tailoring device used for printing

A cutting device and paper technology, which is applied in metal processing and other fields, can solve the problems of complex structure and difficult operation of the cutting device, and achieve the effects of reducing training difficulty, increasing attractiveness, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

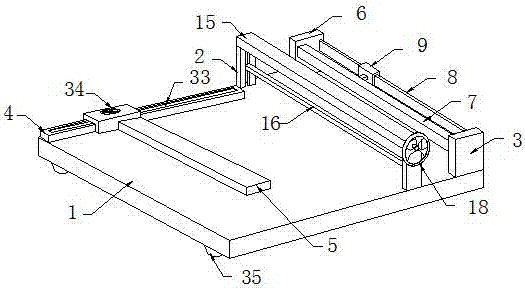

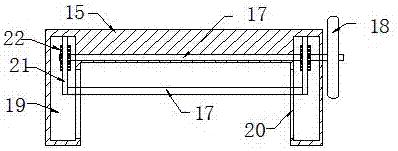

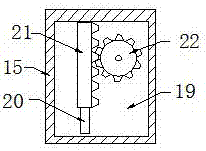

[0023] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a small paper cutting device for printing, including a base 1, a lifting and pressing device 2 and a cutting device 3, and the upper surface of the base 1 is provided with a ruler slide rail 4, the movable ruler 5 is provided on the said ruler slide rail 4, the lifting paper pressing device 2 and the cutting device 3 are arranged on the upper surface of the base 1, and the lifting paper pressing device 2 The setting position of the cutting device 3 is parallel to the setting position of the movable ruler 5, and the lifting and pressing device 2 is located between the movable ruler 5 and the cutting device 3, and the cutting device 3 Including a mounting base 6, a transmission beam 7, a guide rail 8 and a cutter head 9, the mounting base 6 is set to two, and the two mounting bases 6 are respectively arranged on opposite sides of the upper surface of the base 1, so Both ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com