Spiral unloading type tramcar for conveying bulk materials

A bulk material, unloading technology, applied in the direction of transportation of passenger cars, dump trucks, transportation and packaging, etc., can solve the problems of rollover, unstable center of gravity of the mine truck, and the inability to realize the 360-degree rotation of the mine truck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

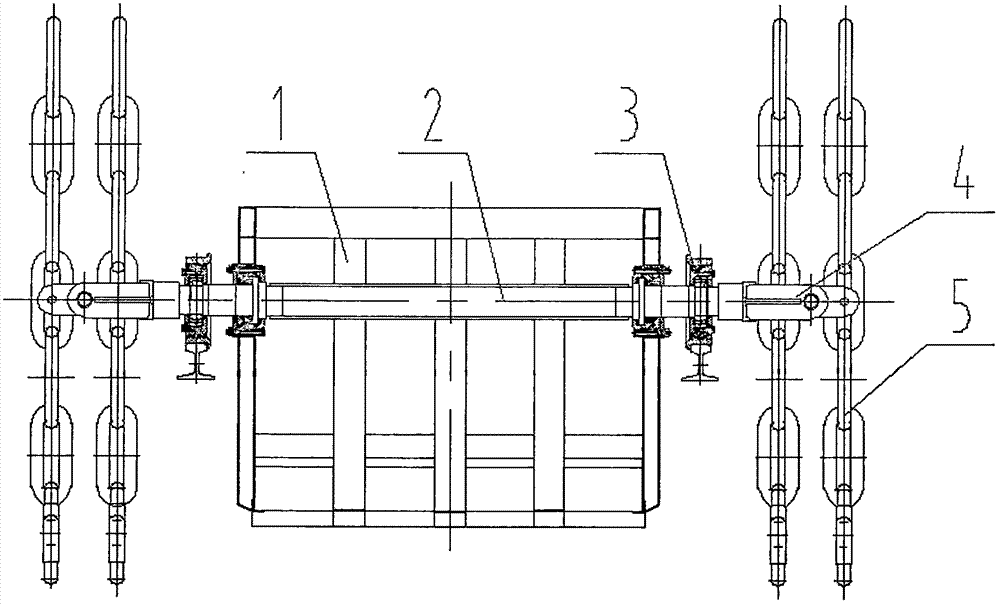

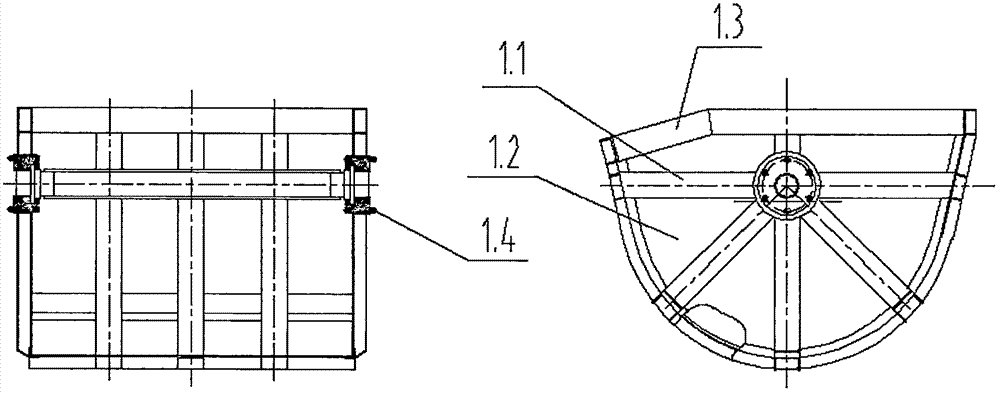

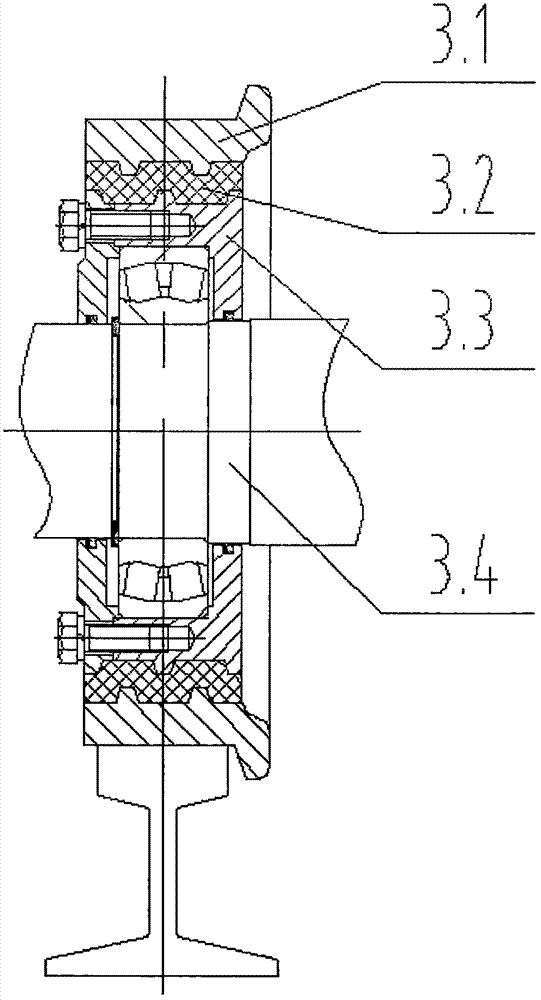

[0018] Such as Figure 1 to Figure 3 As shown, a rotary mine car for bulk material transportation includes a carriage 1, a rotating shaft 2, a mine wheel 3, and a traction assembly 4; each mine car includes a carriage 1, a rotating shaft 2, two Mining wheels 3 and two groups of traction assemblies 4, four traction chains 5, the traction assemblies 4 are symmetrically connected to the two ends of the rotating shaft 2, and the mining wheels 3 are symmetrically installed on the rotating shaft 2 between the carriage 1 and the traction assembly 4; 1 is composed of a carriage load-bearing frame 1.1, a wear-resistant bearing carriage body 1.2, a guide restraint body 1.3 and a rotating bearing 1.4. The carriage 1 can rotate 360 degrees around the rotation axis 2, and the center of gravity of the carriage 1 is alw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com