Star component-anchor rod-ball foundation and construction method thereof

A component and anchor technology, which is applied in the field of star-shaped component-bolt-ball foundation and its construction, can solve problems such as unsatisfactory reinforcement effect, limited resistance, and large engineering volume, so as to improve physical and mechanical properties, change construction and Basic form, the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

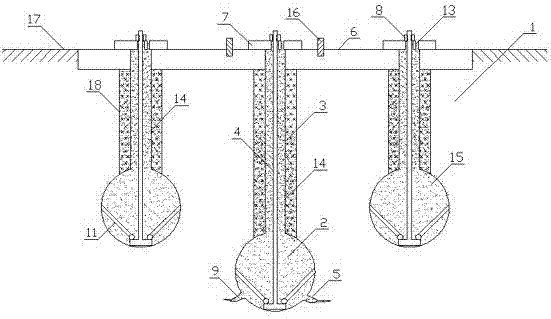

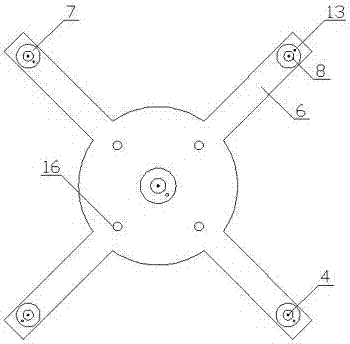

[0041] Such as Figure 1~4 As shown, a star member-anchor-ball foundation, it includes a star member 6 embedded in the ground foundation 1 and the upper surface is flush with the ground 17, one or more anchor rods 4 and anchor rods 4 Matching backing plate 7 and anchor plate 8.

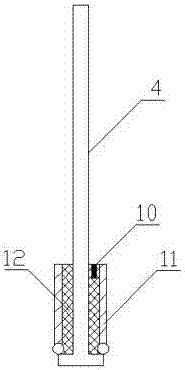

[0042] The star member 6 is provided with several radially protruding outriggers, the center of which is provided with an anchor hole I; the center of the backing plate 7 is provided with an anchor hole III; A support rod 11; a water-resistant explosive 12 with a detonator 10 is installed around the lower part of several anchor rods 4, and several support rods 11 are bound around the water-resistant explosive 12; The root rods 11 are all anchored to the enlarged head, and their top ends respectively pass through the anchor hole I of the corresponding position of the star-shaped member 6, and pass through the anchor hole III of the backing plate 7 to connect with the anchor plate 8.

[0043] Wherein:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com