Ball-anchor rod-starlike component foundation and construction method thereof

A component and bolt technology, applied in the field of ball-anchor-star component foundation and its construction, can solve problems such as time-consuming, high cost, environmental damage, etc., and achieve improved physical and mechanical properties, simple structure, and reduced spoilage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

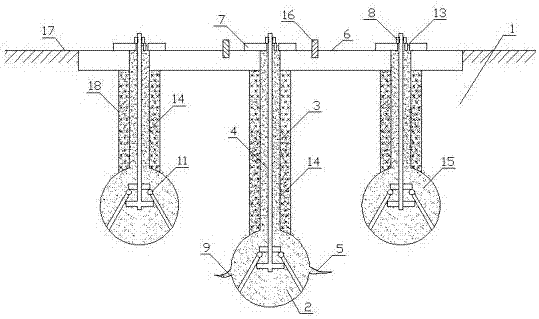

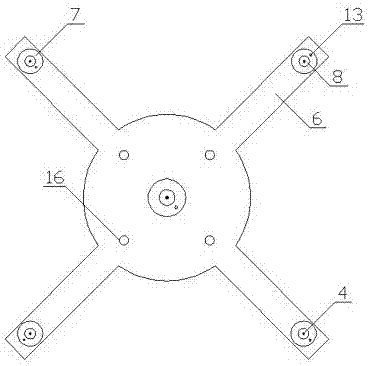

[0042] Such as Figure 1~3 As shown, the ball-bolt-star member foundation, it includes a star member 6 embedded in the ground foundation 1 and the upper surface is flush with the ground 17, one or more anchor rods 4 and matching with the anchor rod 4 Backing plate 7 and anchor plate 8.

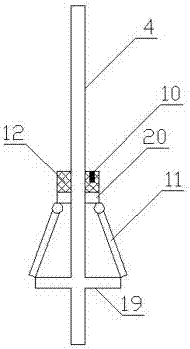

[0043] The star member 6 is provided with several radially protruding outriggers, the center of which is provided with an anchor hole I; the center of the backing plate 7 is provided with an anchor hole III; the anchor 4 includes a rod body, a sleeve 20 and several branches. Rod 11; a steel circular horizontal plate 19 is fixedly connected to the lower part of the rod body, and a sleeve 20 sliding up and down along the rod body is sleeved on it; one end of several poles 11 is hinged around the sleeve 20, and the other ends are all placed Connected to the periphery of the circular horizontal plate 19; close to the upper edge of the sleeve 20 and arranged around the rod body with a water-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com