Method for preventing water tank from freezing and cracking and toilet

A water tank and freeze-cracking technology, which is used in flushing equipment with water tanks, water supply devices, valve operation/release devices, etc. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

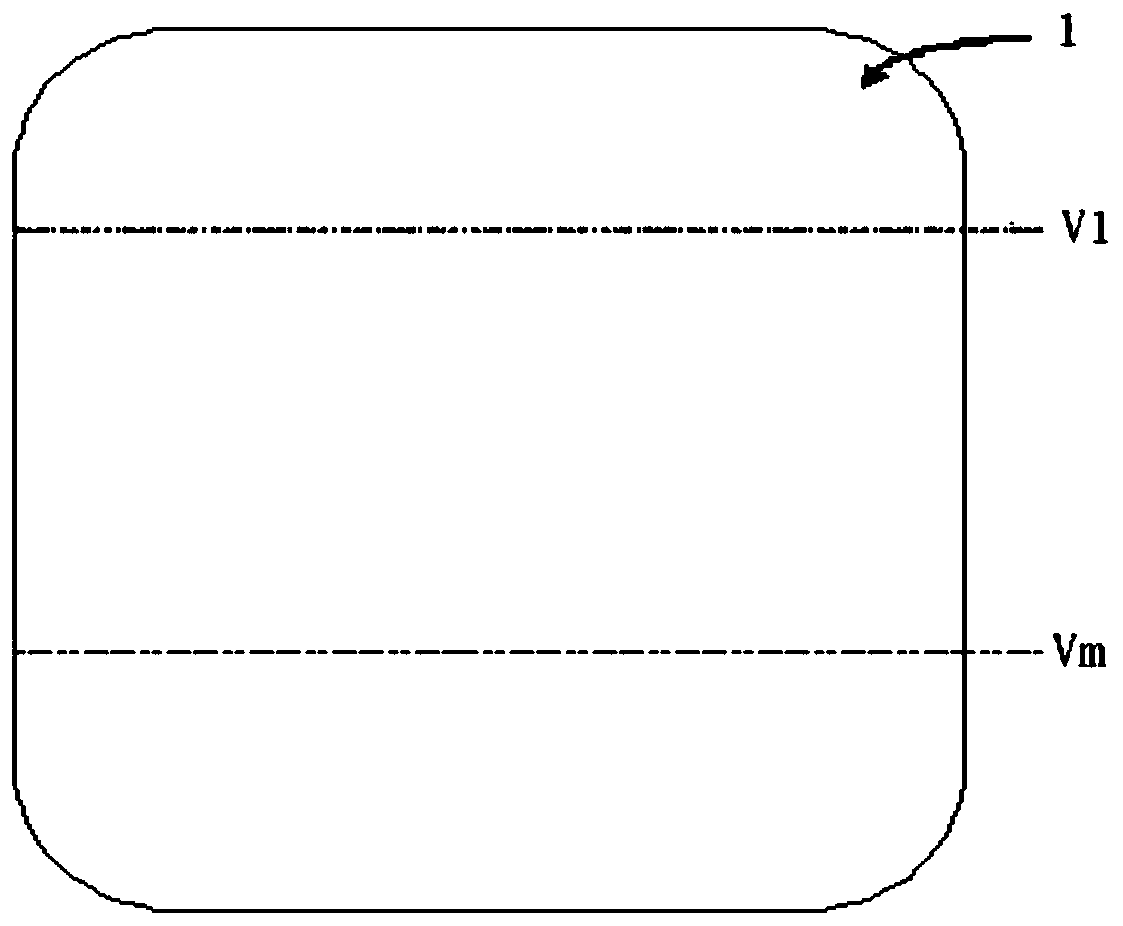

[0027] Such as figure 1 As shown, the present invention provides a method for preventing the water tank from freezing and cracking, comprising the following steps: the control unit controls the valve to inject water into the water tank to the steady-state water level Vm; Water is injected to the flushing water level Vn, where n is a positive integer greater than or equal to 1; the steady-state water level Vm is at least lower than the maximum value of the flushing water level Vn. The method for preventing the water tank from freezing and cracking according to the invention can protect the water tank, reduce the risk of freezing or freezing the water tank of the toilet in a cold environment, and does not affect the use of the flush toilet by users.

[0028] figure 1 As shown, when the toilet is a single-flush toilet, after the control unit detects the user's use signal or instruction, it continues to fill the water tank to the flushing water level V1; the steady-state water le...

Embodiment 2

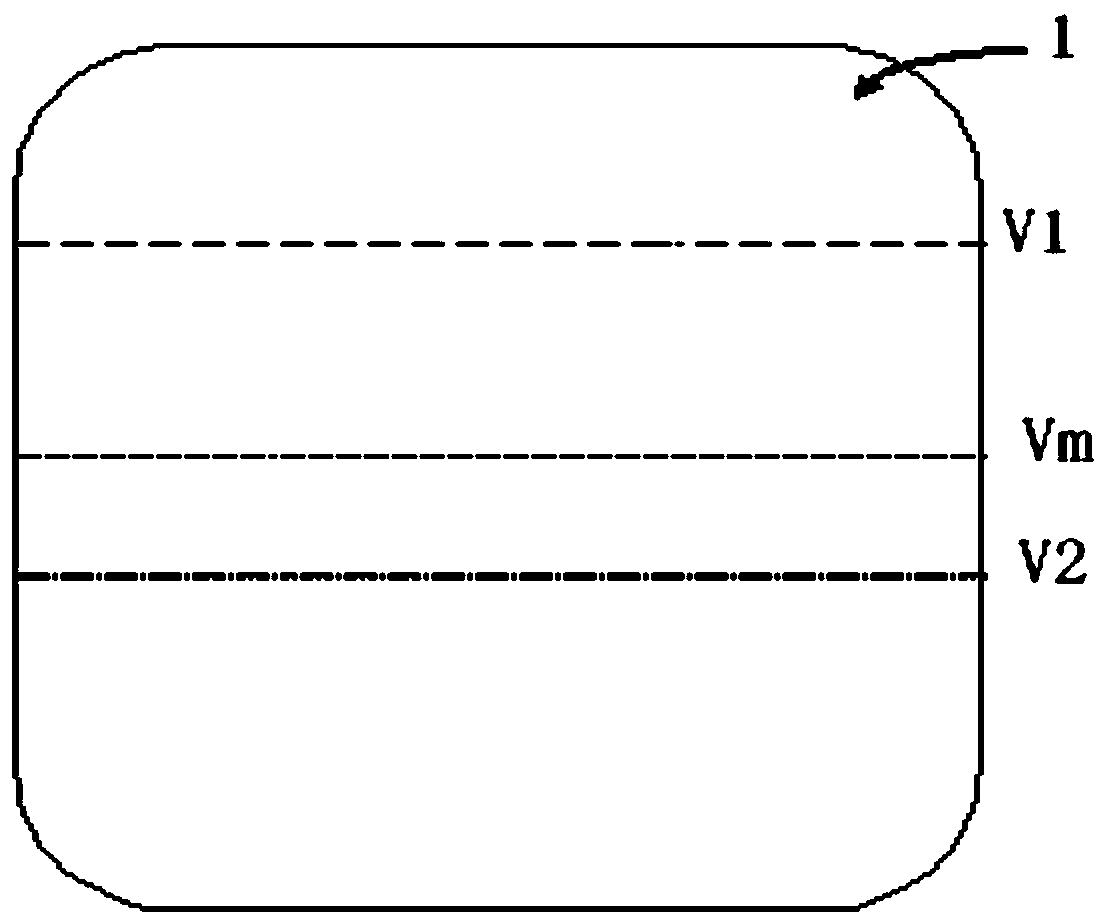

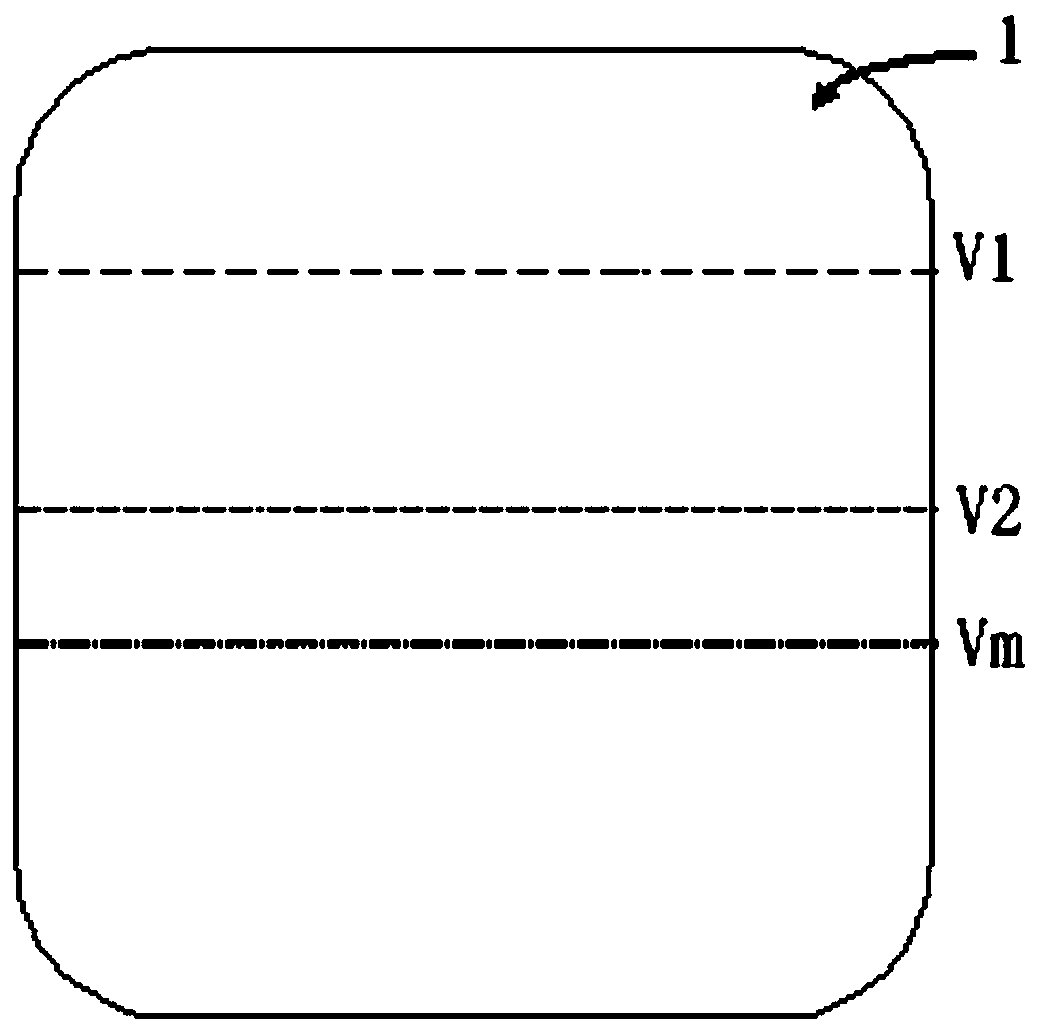

[0033] The invention provides a method for preventing freezing and cracking of a water tank, comprising the following steps: the control unit controls the valve to inject water into the water tank to the steady-state water level Vm; after the control unit detects the user's use signal or instruction, it continues to inject water into the water tank until flushing The water level Vn, n is a positive integer greater than or equal to 1; the steady-state water level Vm is at least lower than the maximum value of the flushing water level Vn. figure 2 As shown, when the toilet is a dual-flush toilet, the flushing water level Vn includes a large flushing water level V1 and a small flushing water level V2; the large flushing water level V1 is higher than the small flushing water level V2.

[0034] Such as figure 2 As shown, one of the preferred methods is that the steady-state water level Vm is lower than the flushing water level V1 of the large flush, and the steady-state water lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com