Self-weight falling prevention mechanism of lifting scaffold for building

A technology for lifting scaffolding and buildings, which is applied to building structures, accessories of scaffolding, scaffolding supported by house structures, etc., can solve the problems of high manufacturing precision requirements of clutch devices and automatic triggers, affecting product promotion, and high product costs. To achieve the effect of easy promotion and implementation, good anti-fall effect and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

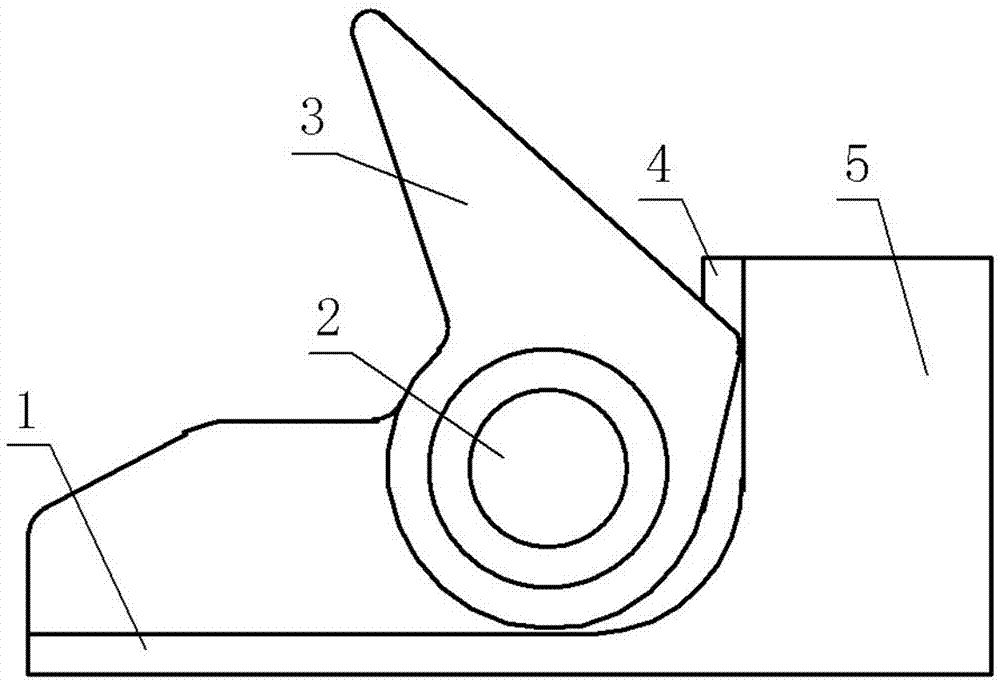

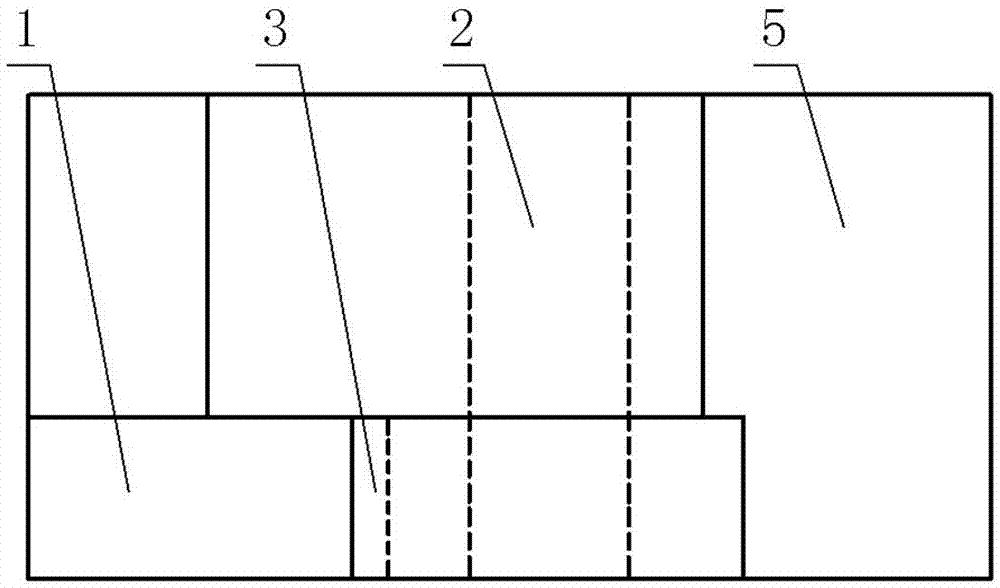

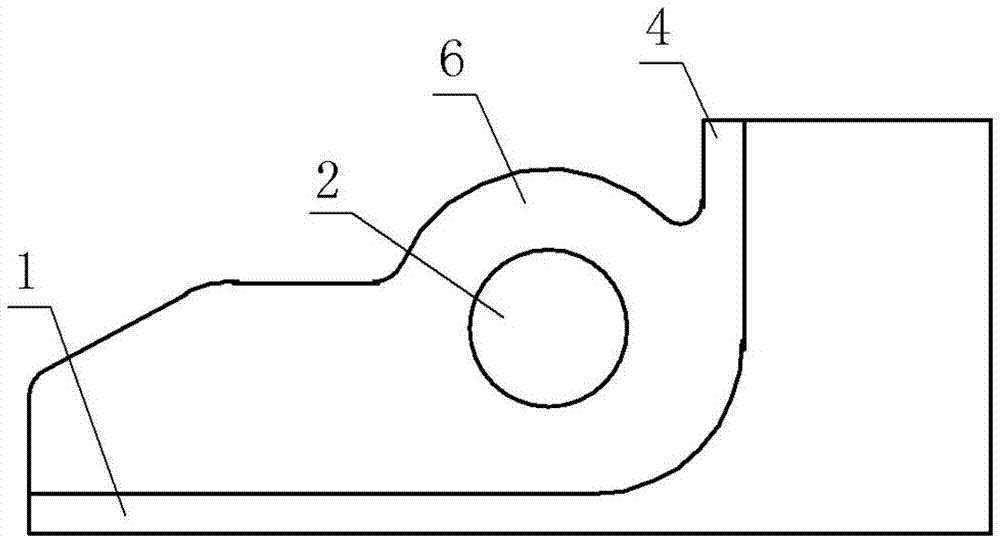

[0015] Example: see Figure 1-Figure 3 , in the figure, 1-bottom baffle, 2-axis hole, 3-swing needle, 4-side baffle, 5-swing needle seat.

[0016] The self-weight anti-falling mechanism of the building lifting scaffold includes a swing needle 3 and a swing needle seat 5, wherein: the swing needle seat 5 is a cuboid structure, and a groove is arranged on the swing needle seat 5, and the groove runs through one end surface of the swing needle seat 5 and a On the side, a bottom baffle 1 and a side baffle 4 are formed, and the side baffle 4 and the swing needle 3 are respectively provided with shaft holes 2, and a connecting piece (not shown in the figure) is arranged through the shaft hole 2, and the swing needle 3 can rotate around the connector, and the side of the shaft hole of the swing needle 3 is provided with a triangular limiting plate, and the top corner of the triangular fiber plate is in contact with the groove wall of the swing needle seat 5.

[0017] The connector i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com