A variable stiffness vibration isolator for vibration isolation of electronic equipment

A technology of electronic equipment and vibration isolator, applied in the field of intelligent vibration isolation, to achieve the effect of improving utilization, good vibration isolation effect, and expanding displacement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

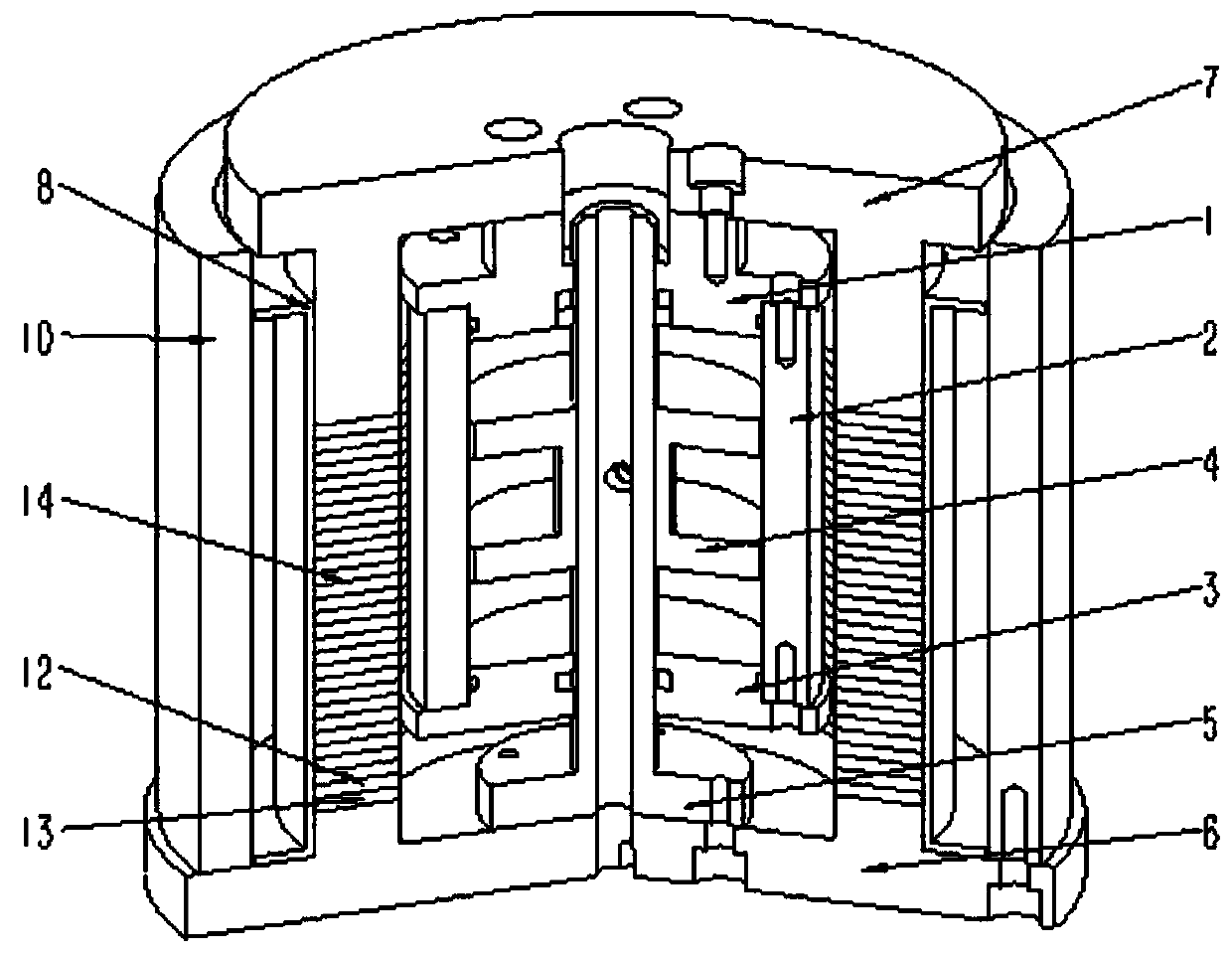

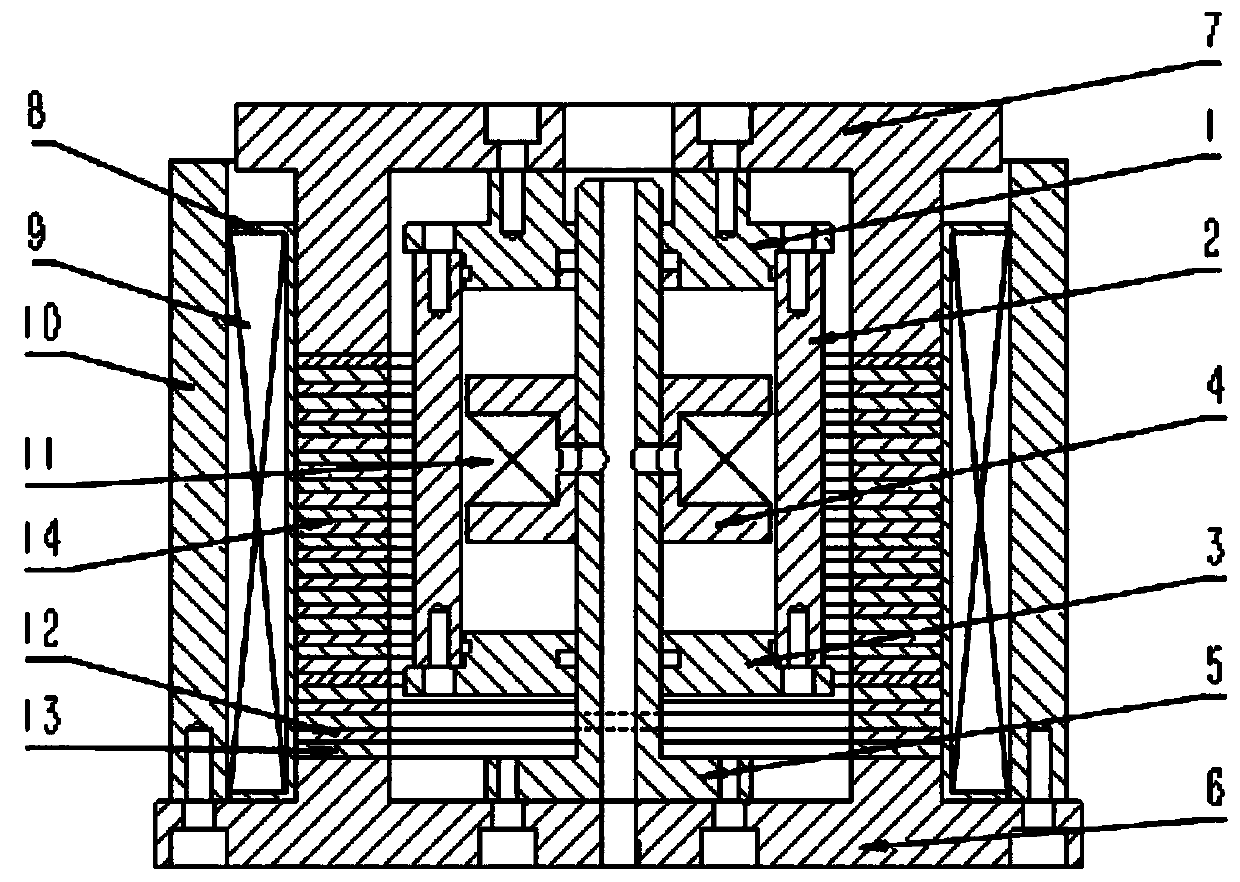

[0027] Such as figure 1 and figure 2 As shown, a variable stiffness vibration isolator for vibration isolation of electronic equipment includes: an upper base 7, a lower base 6, a magnetorheological damper unit and a variable stiffness unit; wherein:

[0028] The magnetorheological damper unit includes a cylindrical cylinder 2 , a piston rod 5 , a piston head 4 , an upper end cover 1 and a lower end cover 3 . The upper end cover 1 is fixed on the top of the cylinder 2, and the lower end cover 3 is fixed on the bottom of the cylinder 2; in this embodiment, the upper end cover 1 and the lower end cover 3 are respectively fixedly connected to the cylinder 2 by screws, but not limited thereto, It can also be fixed by welding or riveting. The upper end cover 1 is fixedly connected to the upper base 7; in this embodiment, the upper base 7 is fixedly connected to the upper end cover 1 by screws, but it is not limited thereto, and can also be fixed by welding or riveting. The insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com