Liquid gas storage tank safety filling and leakage prevention remote monitoring system and application method

A remote monitoring system and technology for liquefied gas tanks, applied in container filling methods, container discharge methods, equipment loaded into pressure vessels, etc. Standardization and other issues to achieve the effect of improving security and remote monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

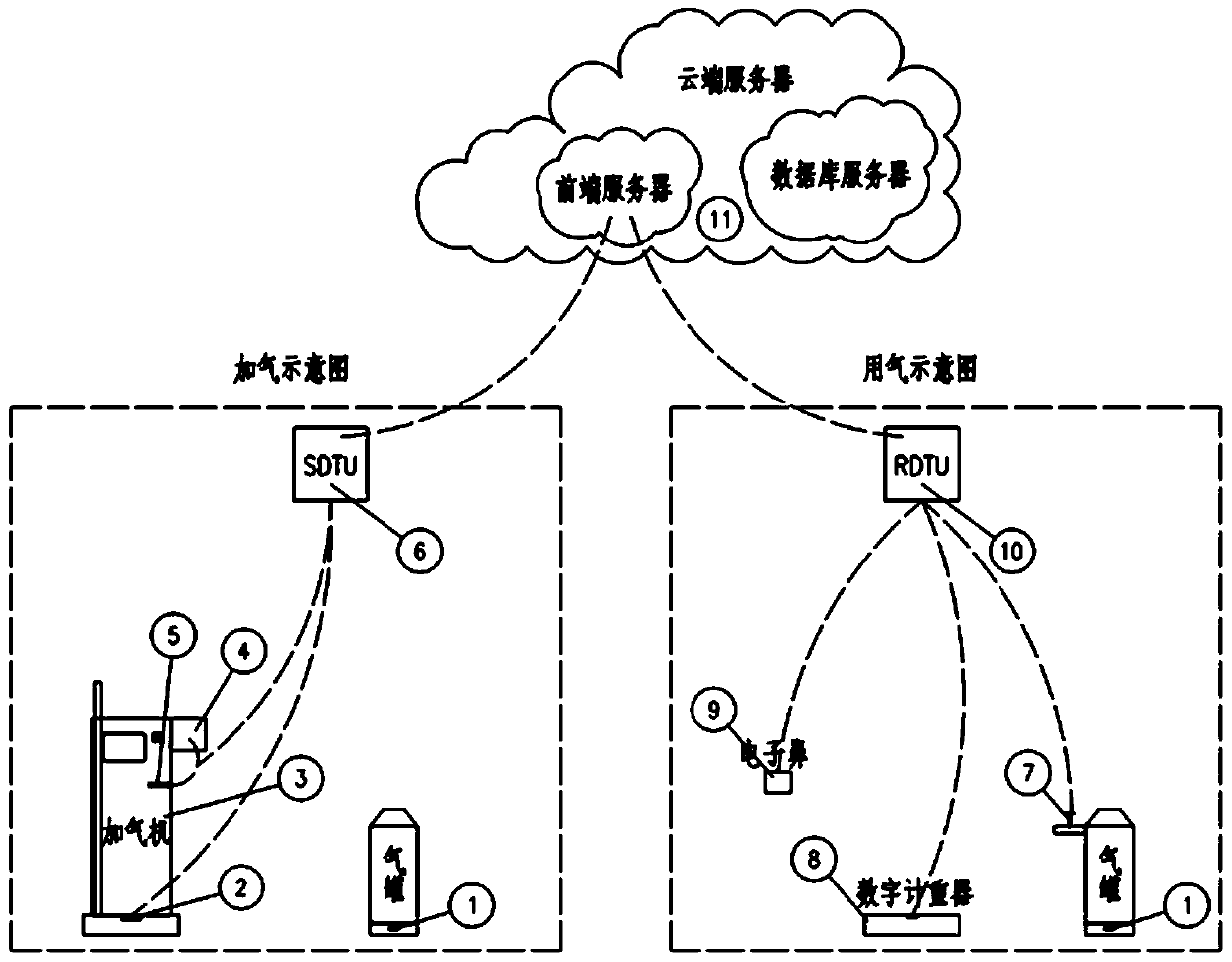

[0018] A remote monitoring system for safe filling and leak prevention of liquefied gas tanks, comprising: a gas tank, a liquefied gas filling unit, a user unit and a cloud server, characterized in that:

[0019] gas tank As a carrier gas container, a digital electronic tag based on RFID technology is installed at the bottom of the gas tank , as the gas tank ID card when liquefied gas is filled and used by the user, so that it can be identified.

[0020] The liquefied gas filling unit includes a filling machine, a gas tank identification unit , gas dispenser control unit , Dispenser display identification control center , Filler identification card , Wireless data transmission control unit based on SDTU technology . The liquefied gas filling unit may be a liquefied gas filling station. The filler identification card is worn by the filler at a designated position in the form of an ID card or a wristband.

[0021] gas tank identification unit , gas dispenser con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com