Large-scale vibration liquefaction test system and design method

A technology of vibration liquefaction and test design, applied in the field of civil engineering, can solve the problems of unformed design method, inability to guide large-scale vibration liquefaction test environment, artificial simulation, etc., and achieve low test economic cost, strong expandability, and accurate control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

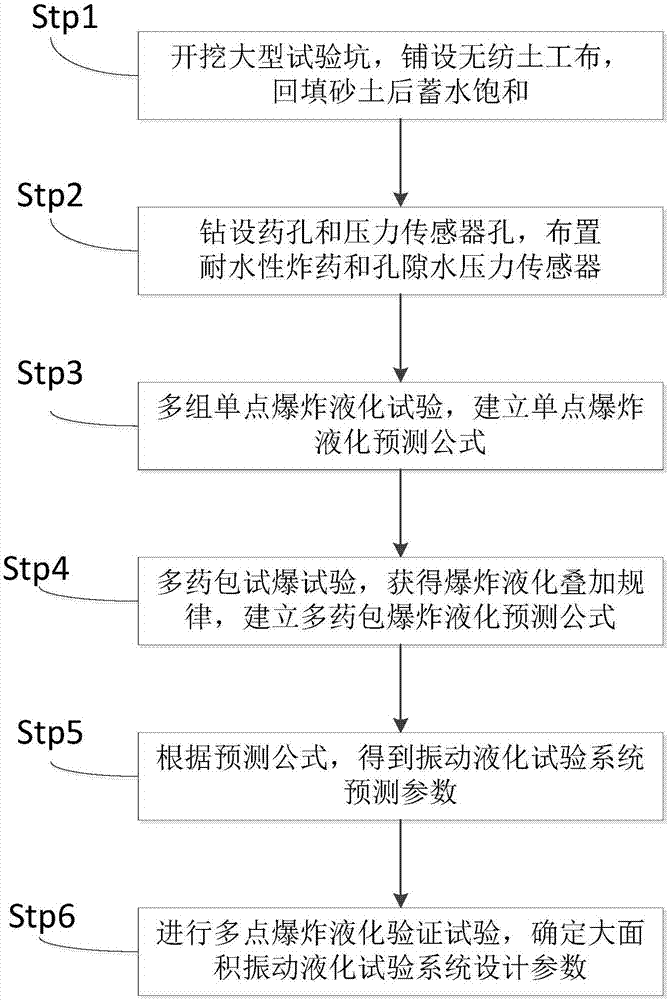

[0043] like figure 1 Shown, it is the flowchart of large-scale vibration liquefaction experiment design method of the present invention, and this design method comprises the following steps:

[0044] Stp1. Excavate a large test pit in the field, lay non-woven geotextiles on the pit wall to form a backfill area, and then fill the pit with sand and store water to saturate.

[0045] Stp2. Drilling a plurality of charge holes and pore water pressure sensor holes in the test pit, and arranging water-resistant explosives and pore water pressure sensors in the charge holes and pore water pressure sensor holes respectively.

[0046] Stp3. Adjust the charge and buried depth of water-resistant explosives to conduct multi-group single-point explosion liquefaction tests, use numerical models to analyze the effects of charge and burial depth on the degree and range of liquefaction, establish a single-point explosion liquefaction prediction formula, and obtain site closure Critical proport...

Embodiment 2

[0052] This embodiment includes the following steps on the basis of the foregoing embodiments:

[0053] Stp1. Excavate a large test pit in the field, lay non-woven geotextiles on the pit wall to form a backfill area, then backfill sand in the pit and store water to saturation, store water for 21 days, and determine the density of the site through the static penetration test. The backfill material of the present invention is controllable. The test pit is backfilled with fine sand by means of throwing and rolling by an excavator. The compactness of the site can be controlled by the backfill method, and other soil materials such as clay can be filled in the pit according to the test requirements. Filling conditions can more accurately grasp the law and characteristics of the actual soil liquefaction response.

[0054] Stp2. Drill a plurality of charge holes and pore water pressure sensor holes in the test pit, arrange water-resistant explosives and pore water pressure sensors in ...

Embodiment 3

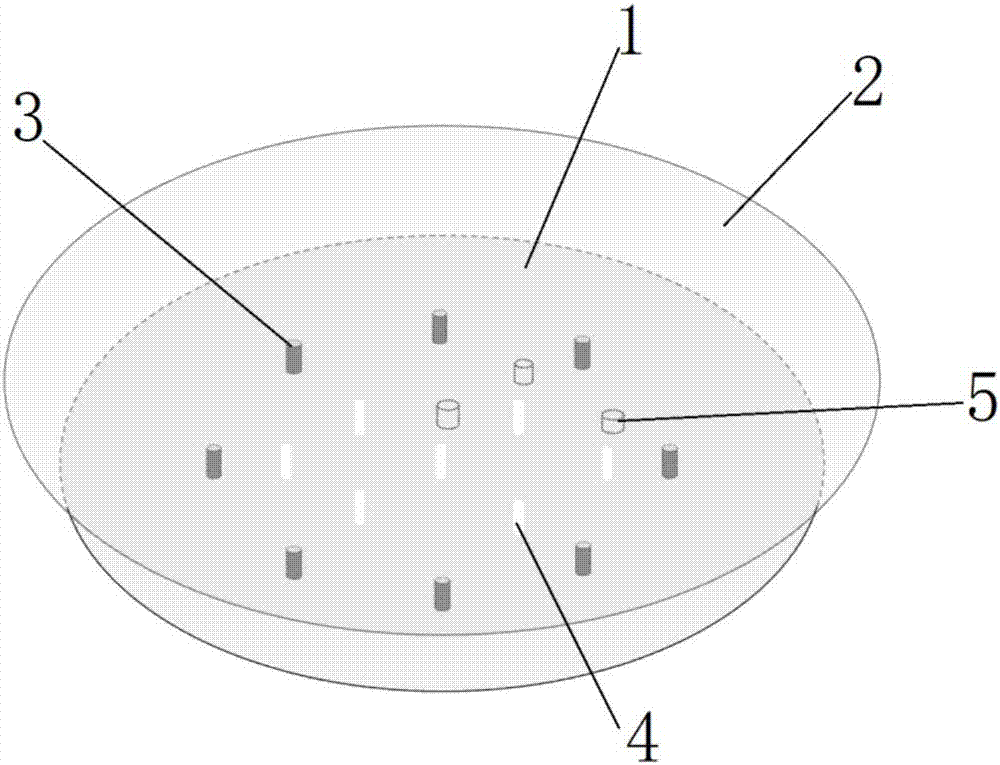

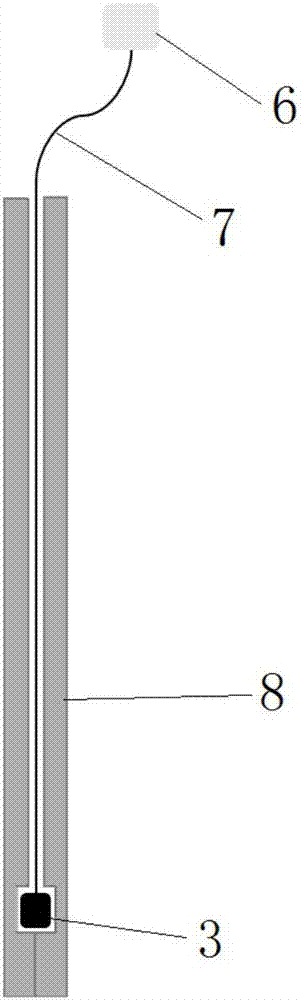

[0066] to combine figure 2 As shown, it is a structural diagram of a large-scale vibration liquefaction test design system of the present invention, and the system includes a test pit 1, an explosion module and a data acquisition module. The test pit 1 is used for vibration liquefaction test, the pit wall of the test pit 1 is covered with non-woven geotextile 2, and the pit is backfilled with saturated sand. The explosion module is used to form a large-area liquefaction site through explosion, and the explosion module includes a plurality of water-resistant explosives 3 . The data collection module is used to collect vibration liquefaction test data, which is arranged in the test pit 1 .

[0067] The test pit 1 is provided with an annular charge distribution ring, and a plurality of charge holes are drilled on the charge distribution ring, and the water-resistant explosive 3 is arranged in the charge holes. The data acquisition device includes a pore water pressure sensor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com