Assembly method of miniature thermal protector

A technology of thermal protector and assembly method, applied in the direction of thermal switch parts, electrical components, electrical switches, etc., can solve the problems of secondary abnormal conduction, small electrical insulation gap, risk, etc., and achieve long reset time, The effect of ensuring consistency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

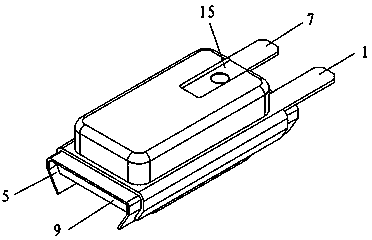

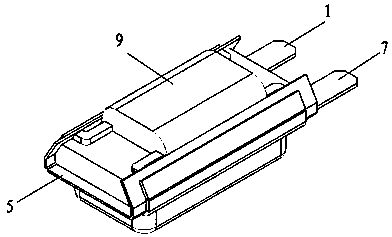

[0039] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

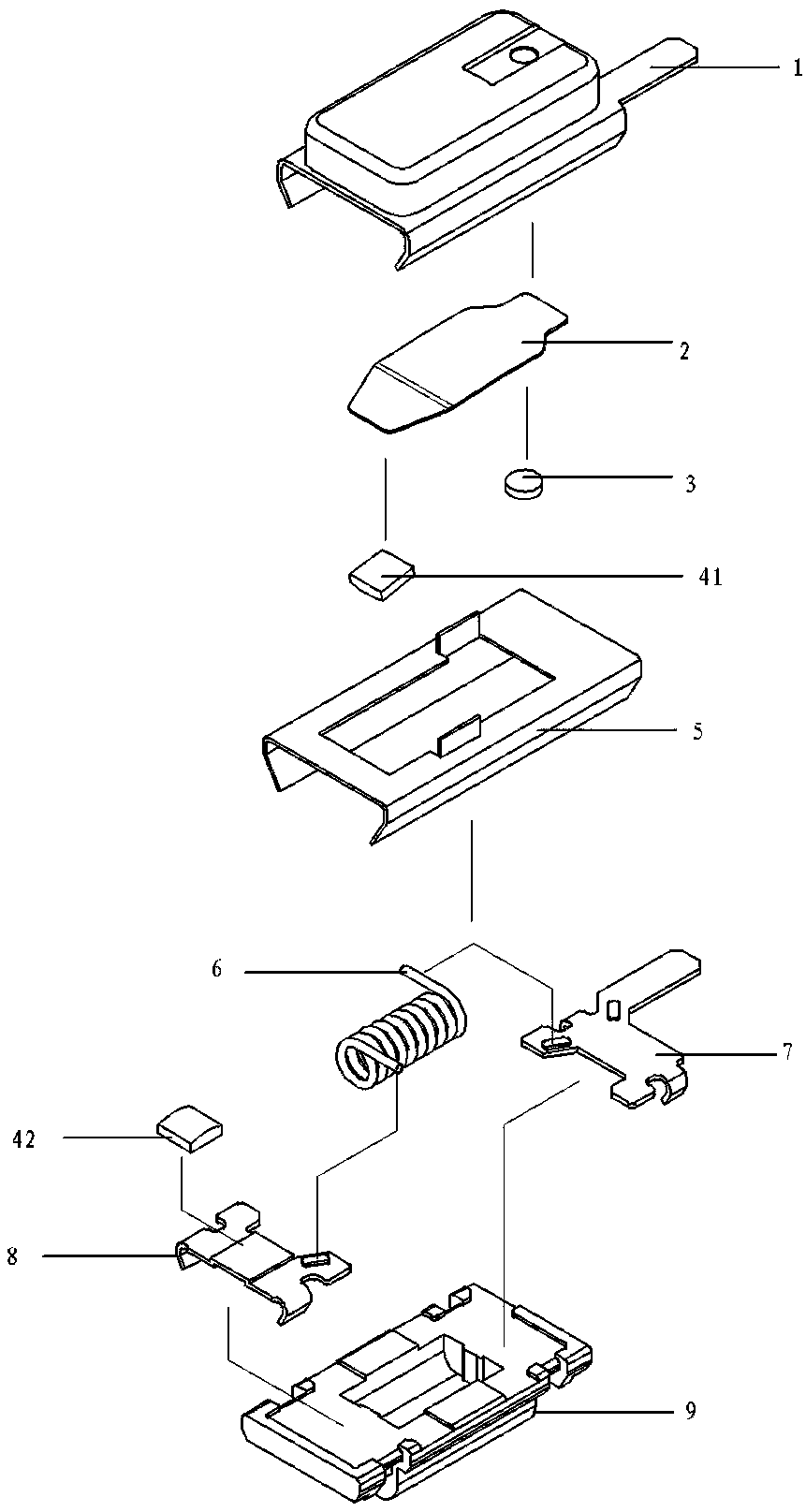

[0040] see Figure 1 to Figure 15 , the miniature thermal protector of the present invention includes a shell 1, a bimetallic sheet 2, a liner 3, a movable contact 41, a static contact 42, an insulator 5, a heating wire 6, an insert 7, a static foot 8, and a non-metallic base 9.

[0041] There is a rectangular boss 14 inside the casing 1, and a circular boss 13 is arranged on the rectangular boss 14. A group of bimetallic strips 2 with a movable contact 41 are reliably connected to the circular boss 13 through the gasket 3, forming a shell assembly 101, and make the effect of welding strength better.

[0042] The casing 1 is provided with a casing output end 11, and the casing 1 is directly connected with two inwardly bent casing corners 1 121 and 2 122, which are fastened to the non-metallic base 9 so as to facilitate the matching conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com