Releasably connected dust collector

A dedusting device and a detachable connection technology, which is applied in the field of detachable and connected dedusting devices, can solve the problems of small dust collection drawers, and achieve the effects of convenient disassembly, convenient handling, and large storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

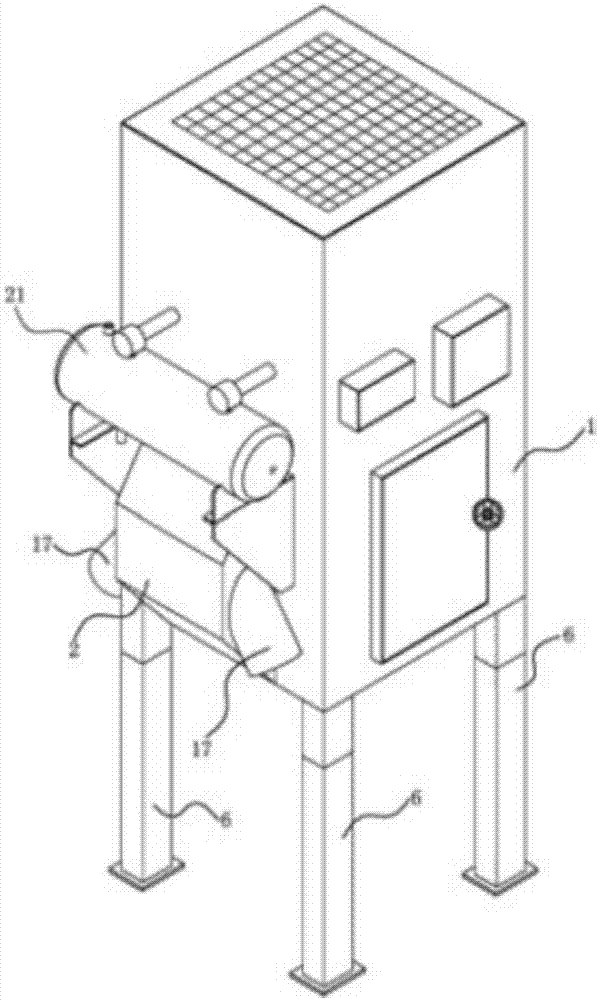

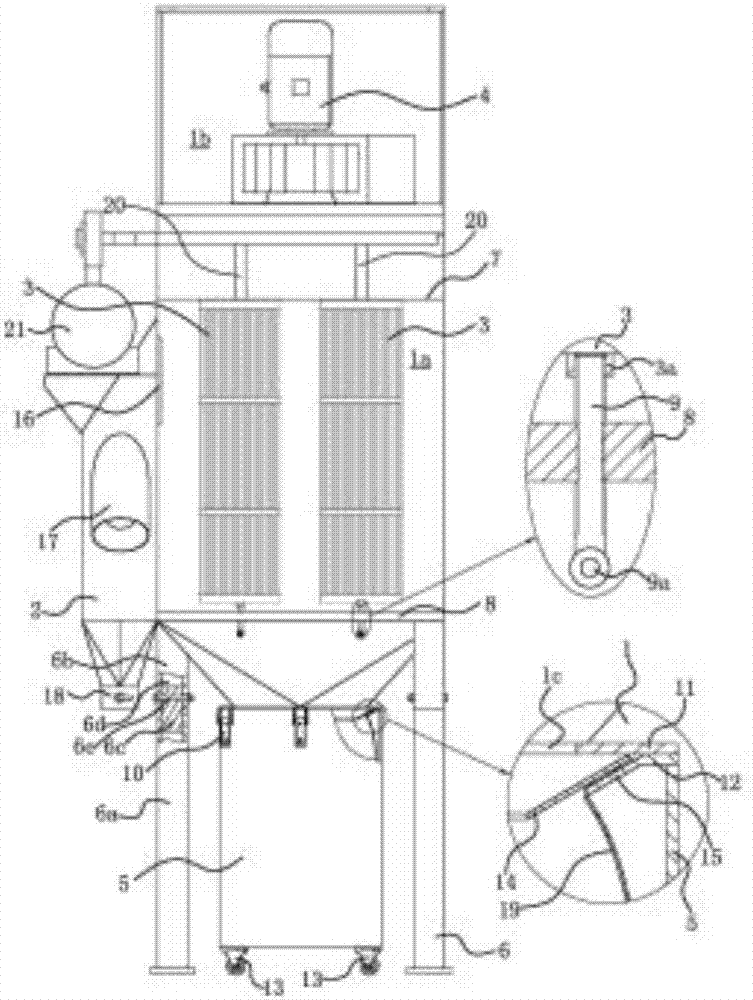

[0016] see figure 1 , 2 As shown, a detachable connection type dust removal device includes a main box body 1, an auxiliary box body 2, a filter cartridge 3, a fan 4, a dust storage barrel 5 and a support foot 6. The main box body 1 is roughly in the shape of a cuboid, and a horizontal partition 7 is fixedly connected to the main box body 1. The partition board 7 has air exhaust holes; the partition board 7 divides the inner cavity of the main box body 1 into dust removal chamber 1a and Fan installation cavity 1b. There is a dust outlet 1c on the bottom plate of the main box body 1. In order to avoid dust accumulation in the main box body 1, the bottom plate is conical, that is, the dust settled on the bottom plate will naturally slide down and be discharged from the dust outlet 1c. . The fan 4 is fixed in the fan installation chamber 1b of the main box body 1 . The filter cartridge 3 is arranged in the dust removal chamber 1a, and the figure in the specification shows tha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap