Drawer type dust collector

A dust collector, drawer-type technology, applied in the direction of dust removal, dispersing particle filtration, cleaning methods and appliances, etc., can solve the problems of poor adaptability, affecting the overall work, dust falling into the lower chamber, etc., to achieve enhanced adaptability ability, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

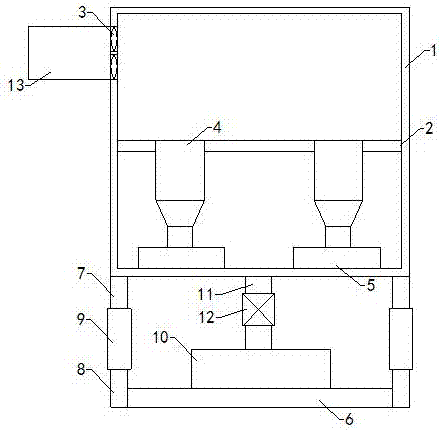

[0011] Such as figure 1 As shown, a drawer-type dust collector of the present invention includes a casing 1, a working chamber is arranged inside the casing, and a partition 2 is arranged transversely in the working chamber to divide the working chamber into an upper chamber and a lower chamber. , the casing is provided with an air inlet, and a fan 3 is arranged on the air inlet, the air inlet communicates with the upper chamber, the lower chamber is provided with a filter bucket 4, and the casing is provided with a dust collection drawer 5, the dust collection drawer is located in the filter bucket bottom, and the filter bucket communicates with the upper chamber; also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com