A kind of material vertical packing method

A vertical and material technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low packing efficiency, high cost of vertical packing, and large area of vertical packing, so as to ensure coherence. Stable effect of sex, out of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

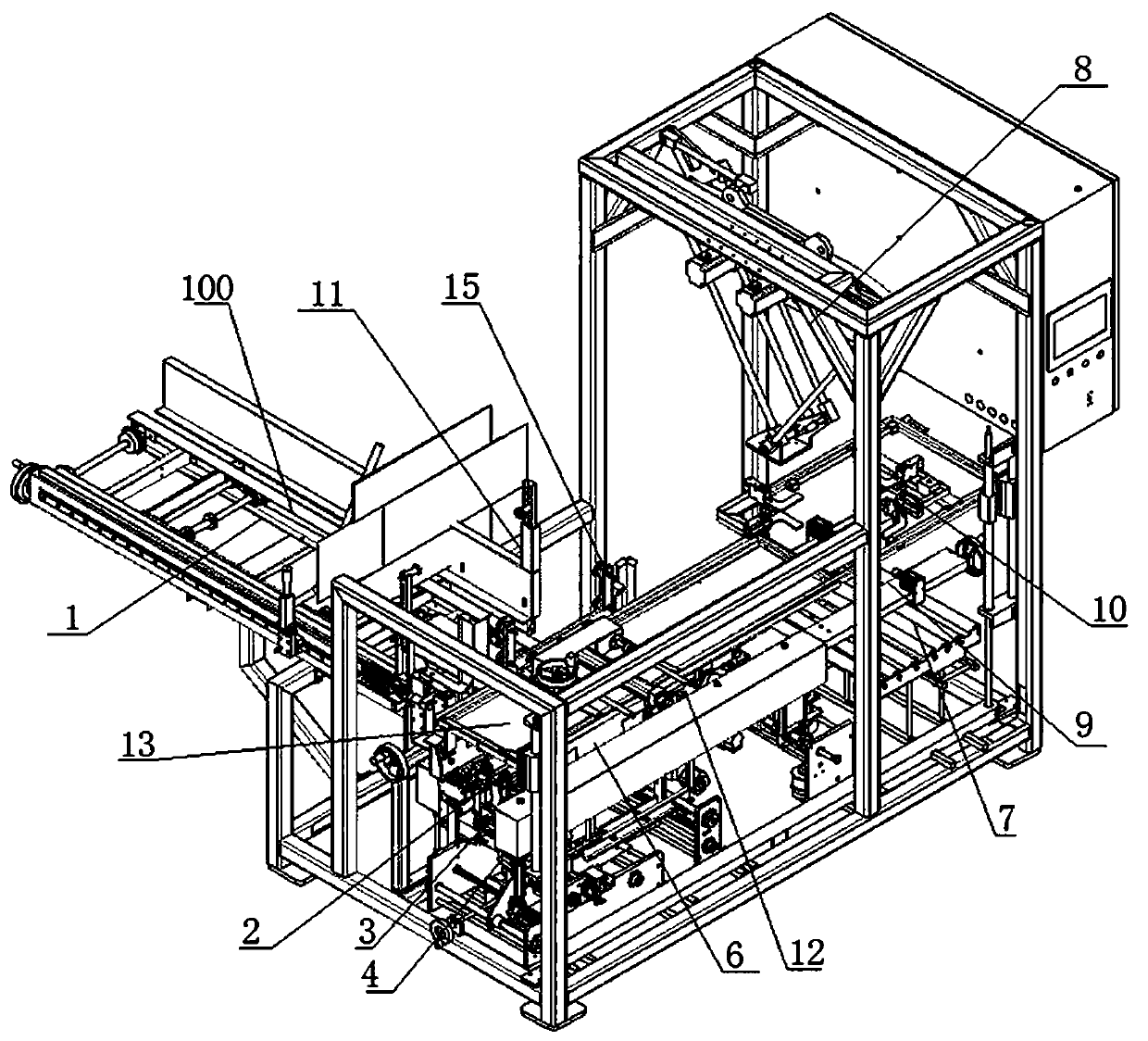

[0075] As a preferred embodiment of the present invention, the present invention discloses:

[0076] A vertical packing method for materials, comprising the following steps:

[0077] A. Box drop step: the folded box is dropped from the storage station to the bottom station of the unpacking and folding box;

[0078] B. Unpacking step: take the connection of the adjacent two sides of the box as the axis, rotate one of the adjacent two sides, open the folded box, and form a box with openings at both ends;

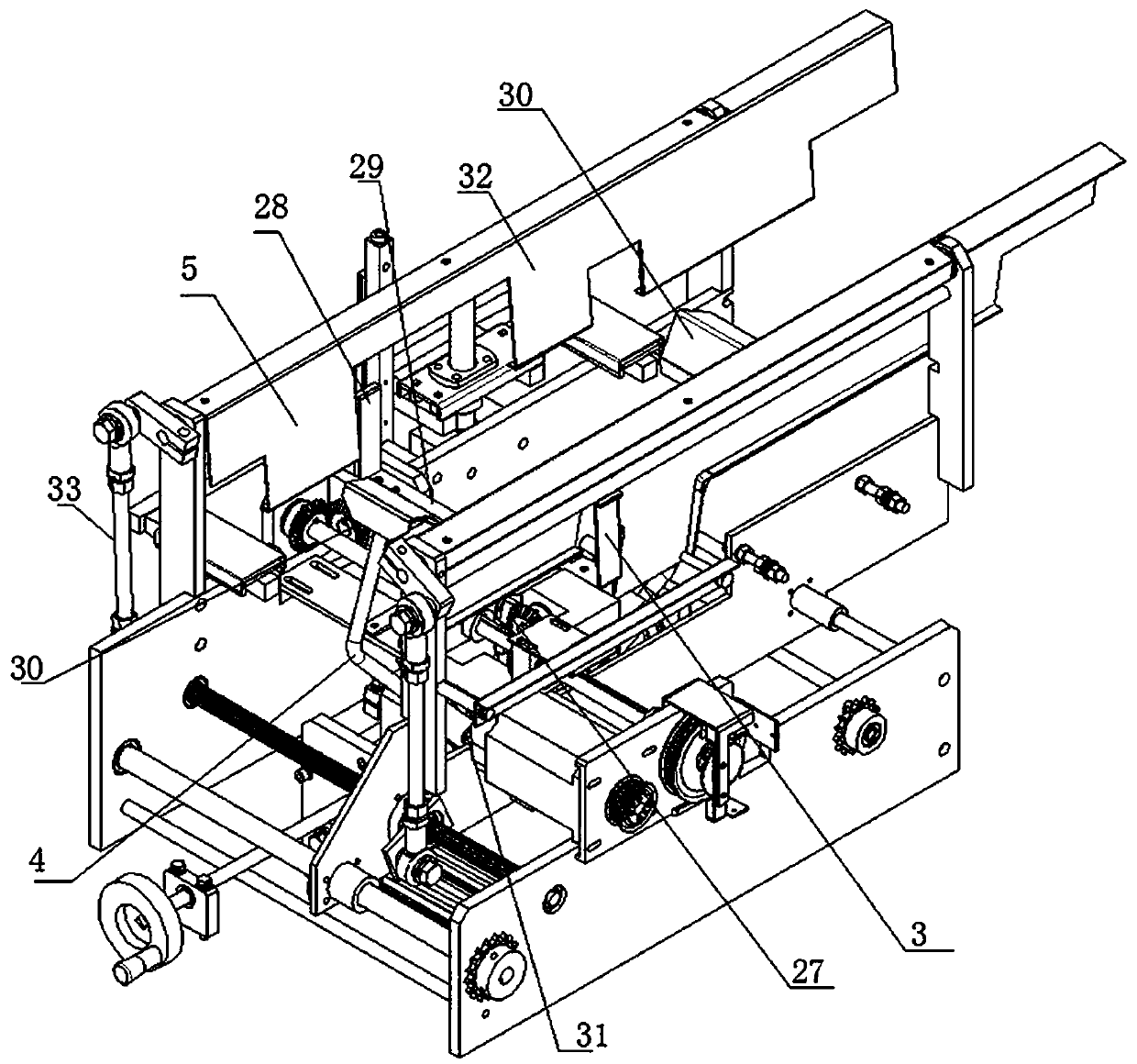

[0079] C. Pre-folding steps of box leaves at the bottom of the box: Fold the box leaves on both sides of the bottom of the box with upper and lower ends open at a certain angle outward, and turn the box leaves at both ends of the bottom of the box with upper and lower ends open inward Folding, the box leaves on both sides of the box bottom that are turned outward at a certain angle are turned inward, so that the box leaves on both sides are folded under the box leaves at both...

Embodiment 2

[0084] As another preferred embodiment of the present invention, this embodiment discloses:

[0085] A vertical packing method for materials, comprising the following steps:

[0086] A. Box drop step: the folded box is dropped from the storage station to the bottom station of the unpacking and folding box;

[0087] B. Unpacking step: take the connection of the adjacent two sides of the box as the axis, rotate one of the adjacent two sides, open the folded box, and form a box with openings at both ends;

[0088] C. Pre-folding steps of box leaves at the bottom of the box: Fold the box leaves on both sides of the bottom of the box with upper and lower ends open at a certain angle outward, and turn the box leaves at both ends of the bottom of the box with upper and lower ends open inward Folding, the box leaves on both sides of the box bottom that are turned outward at a certain angle are turned inward, so that the box leaves on both sides are folded under the box leaves at both...

Embodiment 3

[0094] As another preferred embodiment of the present invention, this embodiment discloses:

[0095] A vertical packing method for materials, comprising the following steps:

[0096] A. Box drop step: the folded box falls from the storage station to the unpacking bottom station through the box storage station and the unpacking and folding bottom station;

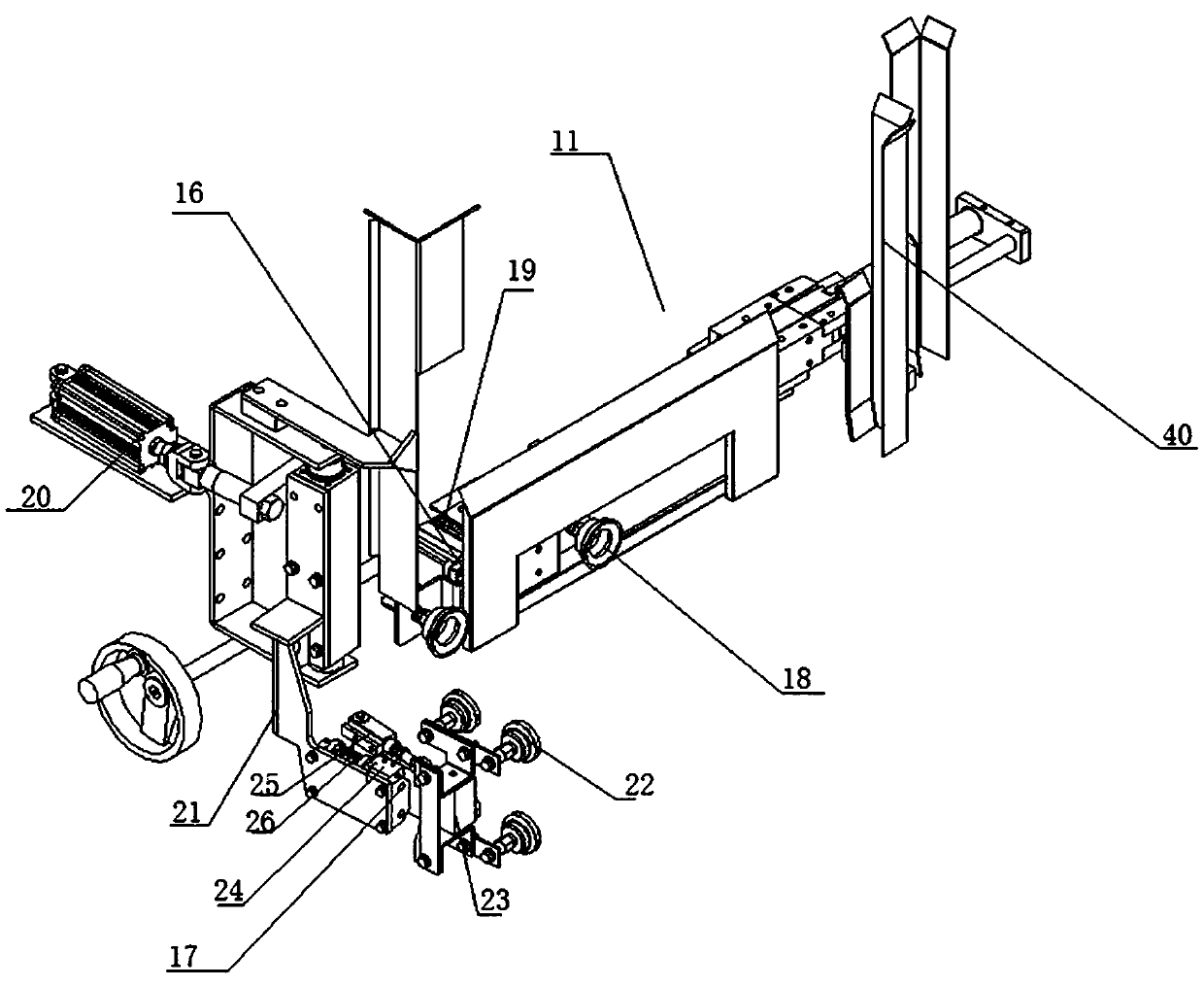

[0097] B. Unpacking step: Fix one side of the adjacent two sides through the solidifying unit of the unpacking mechanism, then suck the other side through the unpacking unit, and turn the unpacking unit so that the other side wraps around the joint of the two sides Rotate to make the folded box open to form a box with upper and lower ends open;

[0098] C. Pre-folding steps of the box leaves at the bottom of the box: through the pre-folded long leaf turning mechanism at the bottom station of the box opening and folding box, the box leaves on both sides are turned outward at a certain angle, and the bottom of the box with up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com