Method for reinforcing steel pipe compression resistance

A technology of compressive performance and steel pipes, which is applied in the direction of construction and building construction, can solve the problems that the cables occupy a large space, are not suitable, and the cables are easy to be damaged, so as to improve the efficiency of strength utilization, save steel, and strengthen The effect of compressive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

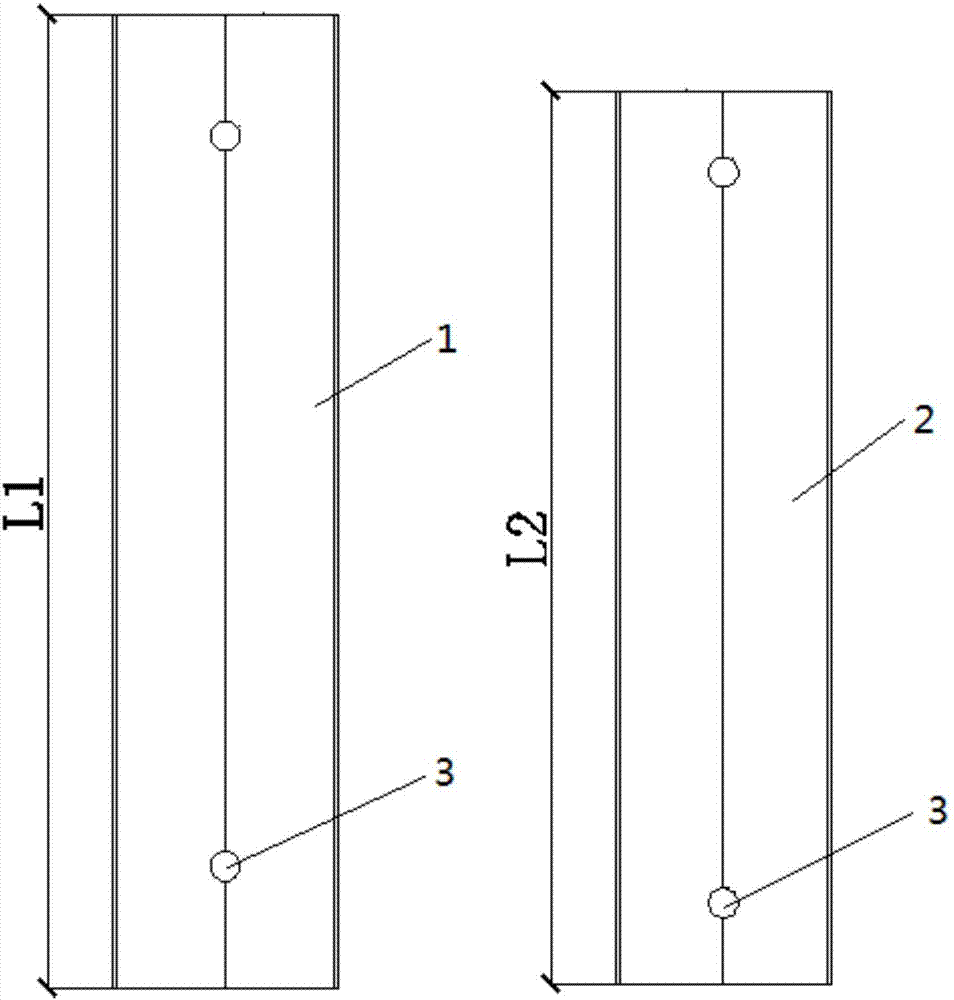

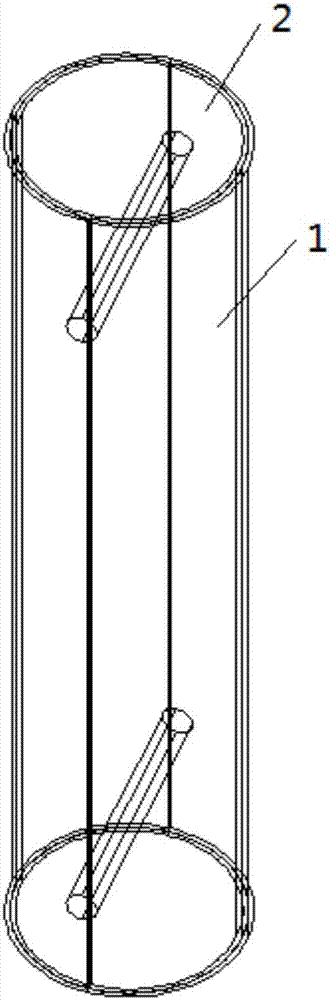

[0012] Such as figure 1 and 2 As shown, the steel pipe of the present invention is made up of inner core pipe 2 and steel pipe 1, and the corresponding position on inner core pipe 2 and steel pipe 1 is provided with pin shaft installation hole 3, under normal temperature condition (being room temperature), the length of inner core pipe 2 L2 is equal to the length L1 of the steel pipe 1 at room temperature, and the outer diameter R2 is greater than the inner diameter r1 of the steel pipe 1 at room temperature. After the inner core pipe 2 is treated with liquid nitrogen, the length L2 of the inner core pipe 2 is smaller than the length L1 of the steel pipe 1 , and the outer diameter R2 is smaller than the inner diameter r1 of the steel pipe 1 .

[0013] Before assembly, put the inner core tube 2 in liquid nitrogen and soak it for a period of tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com