Equipment hoisting transitional supporting platform on ultrahigh building floor and construction method thereof

A technology for supporting platforms and equipment, which is applied in the direction of construction, building structure, and building materials processing, etc., can solve problems such as impact, high risk of hoisting methods, time-consuming and cost-consuming main structure, etc., to achieve low risk and low construction cost. Small, labor cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

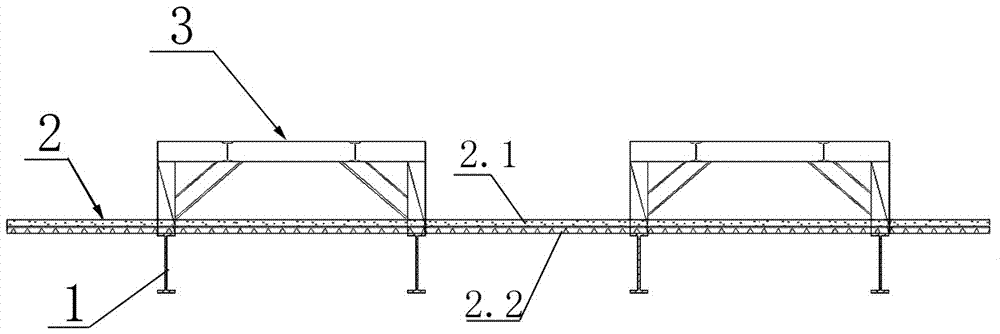

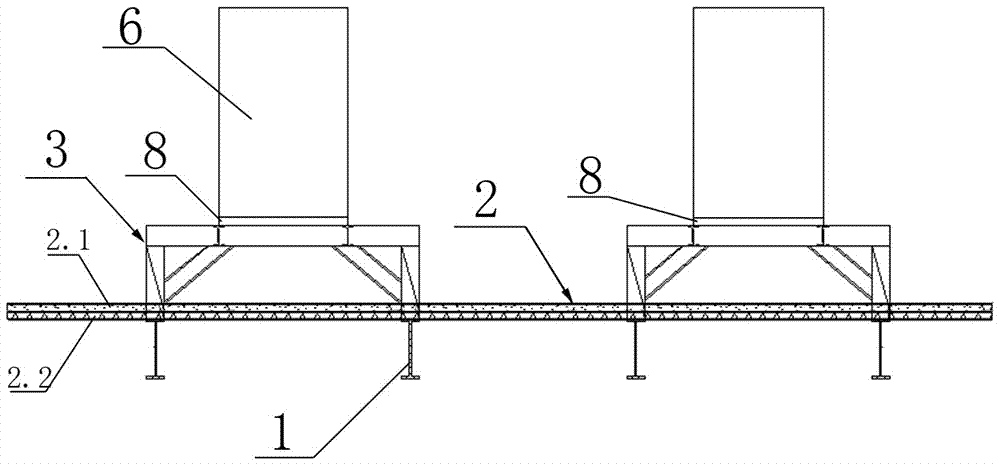

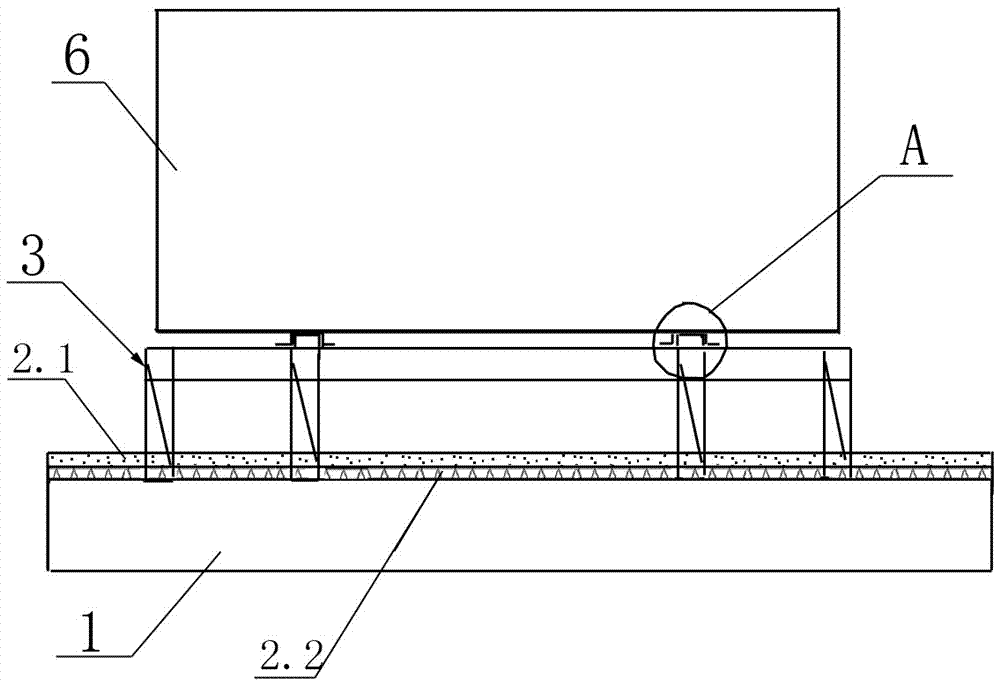

[0053] The invention relates to a support platform and its construction method, in particular to a transitional support platform for hoisting equipment on a super high building floor and its construction method; the transition support platform utilizes the characteristics of super high building structure construction and prefabricates the support during the structural construction stage The frame is pre-installed on the structural steel beam, and the equipment is hoisted by a tower crane. First, the equipment is placed on the supporting platform. On the basis of equipment; so as to solve the technical problems such as the load of the unloading platform cannot meet the requirements during the vertical transportation of large-scale equipment in super high-rise buildings, the multi-layer structure needs to reserve hoisting reserved holes, change the structural design and other technical problems; at the same time, it can also save costs and save construction time The goal.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com