Method for measuring geometrical shape of stratified interface of two-phase flow

A measurement method and interface technology, applied in measurement devices, analytical materials, surface/boundary effects, etc., can solve the problems of fluctuations in the response of dual-ring conductance sensors, unpredictable measurement errors, and large errors in the interface shape of oil-water layers. The effect of real-time dynamic imaging, disturbance avoidance, high sensitivity measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

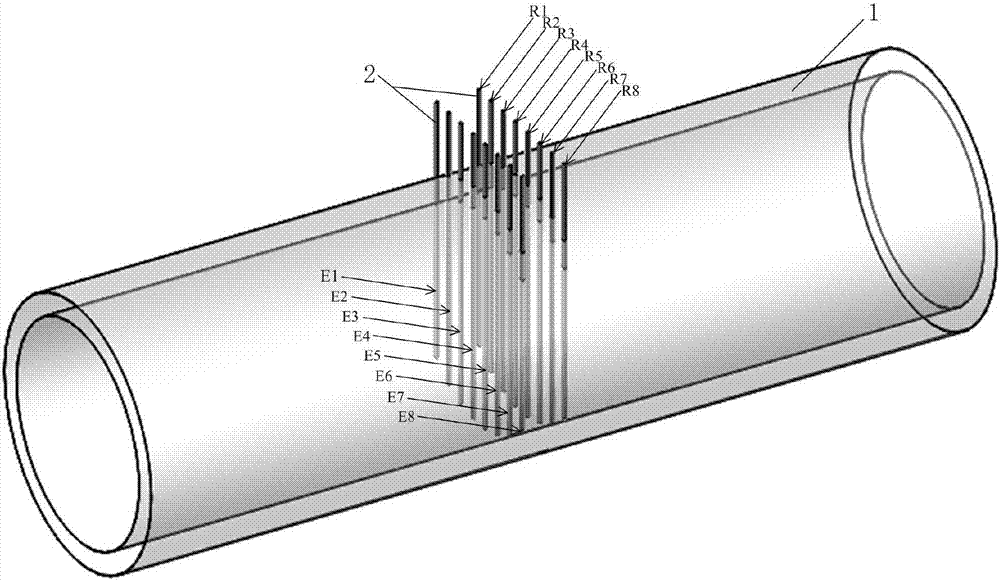

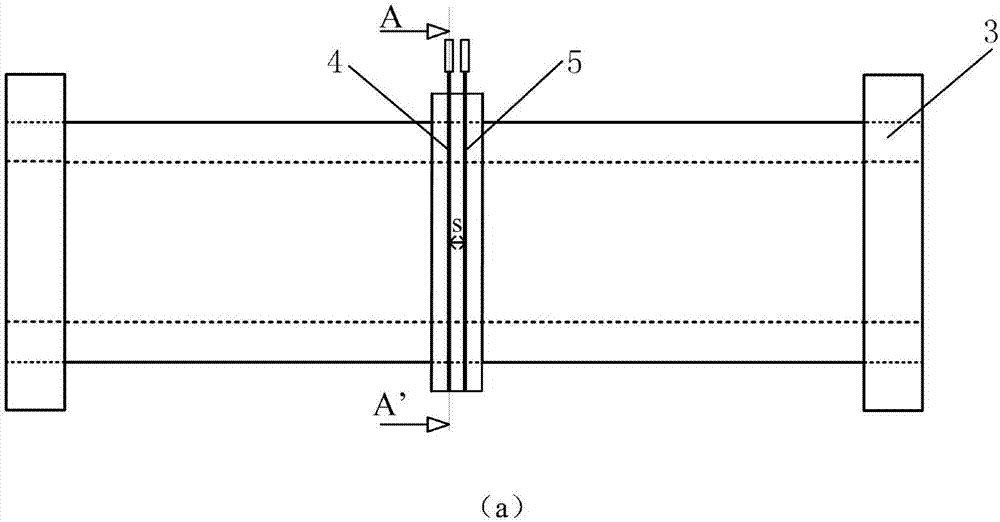

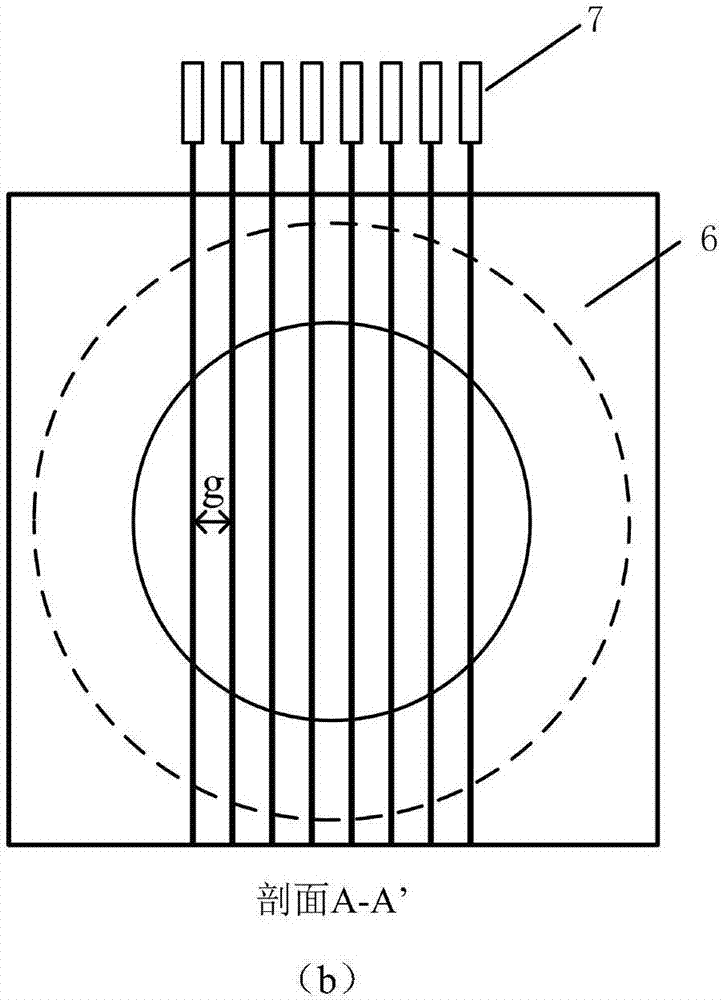

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The parallel line array sensor of the present invention is used to measure the layered interface morphology of two-phase flow with conductivity difference, and its structure is shown in figure 1 and figure 2 . The parallel line array sensor is composed of multiple pairs of parallel line metal electrodes. Taking 8 pairs of parallel line electrodes as an example, E1, E2, E3, E4, E5, E6, E7 and E8 are the excitation electrodes of the sensor, and R1, R2, R3 , R4, R5, R6, R7 and R8 are the receiving electrodes of the sensor. Each electrode presses figure 2 The position shown is mounted on a fixture made of plexiglass (see number 6), the excitation electrode is installed upstream and the receiving electrode is installed downstream. The two ends of the electrode holder are connected with a circular plexiglass pipe. The diameter of each wire electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com