Compressible wall function calculation method considering boundary layer combustion heat release effect

A calculation method and boundary layer technology, applied in calculation, computer-aided design, electrical digital data processing, etc., can solve the problems of not considering the exothermic effect of chemical reaction, reducing the amount of calculation, and the difficulty of applying scramjet wall function method, etc. To achieve the effect of improving the efficiency of numerical simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

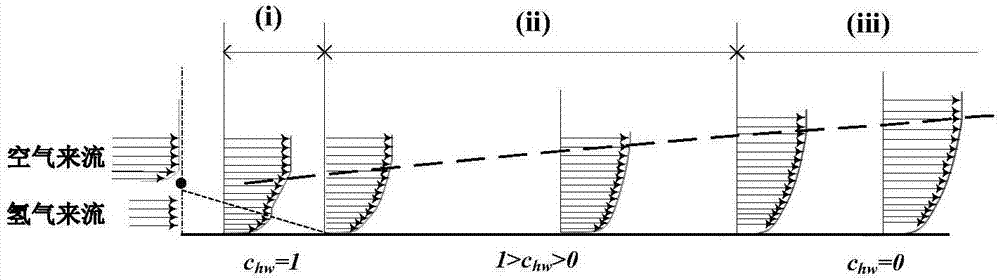

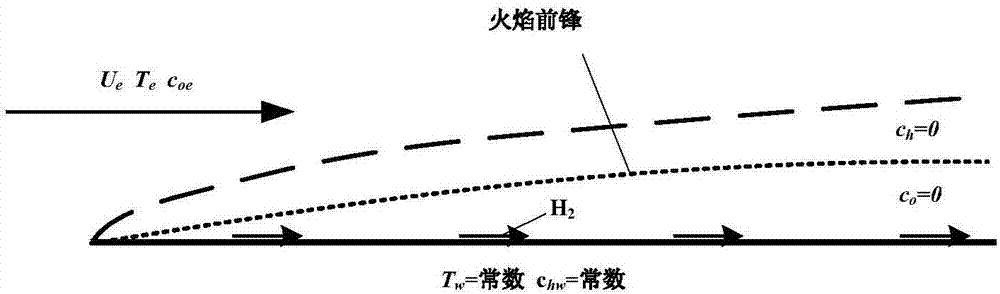

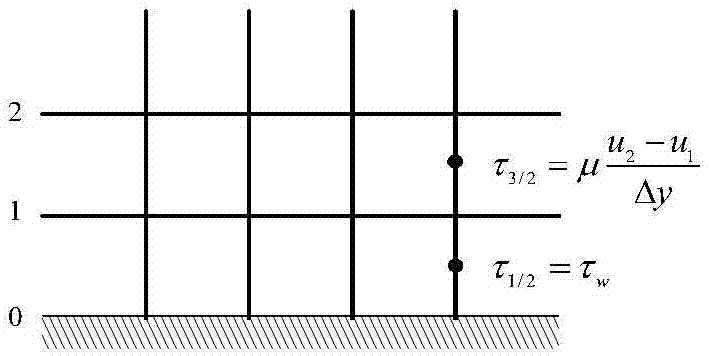

[0062] Embodiment: Based on the compressible wall function method considering the boundary layer combustion heat release effect proposed in the present invention, for Figure 4 An experimental case shown involving boundary layer combustion was simulated. Air flow conditions are: Mach number 4.42, temperature 1120K, pressure 83kPa. Hydrogen is injected into the supersonic compressible turbulent boundary layer formed by air at the speed of sound through a step with a height of 3mm on the upper wall, Figure 5 The temperature distribution nephogram obtained from the calculation given in can see the diffusion combustion flame formed in the boundary layer. Figure 6 Firstly, it is shown that in the dense grid (the grid scale of the first layer of the wall is 5×10 -7 m, the corresponding y + Comparing the ratio of friction resistance and heat flow with / without boundary layer combustion calculated without using wall function under the condition of about 1) with the experimental da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com