Insulated shell with integrated function and manufacturing method thereof

A technology of insulating shell and manufacturing method, which is applied in the field of insulating shell of vacuum interrupter and its manufacturing, and can solve problems such as development constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

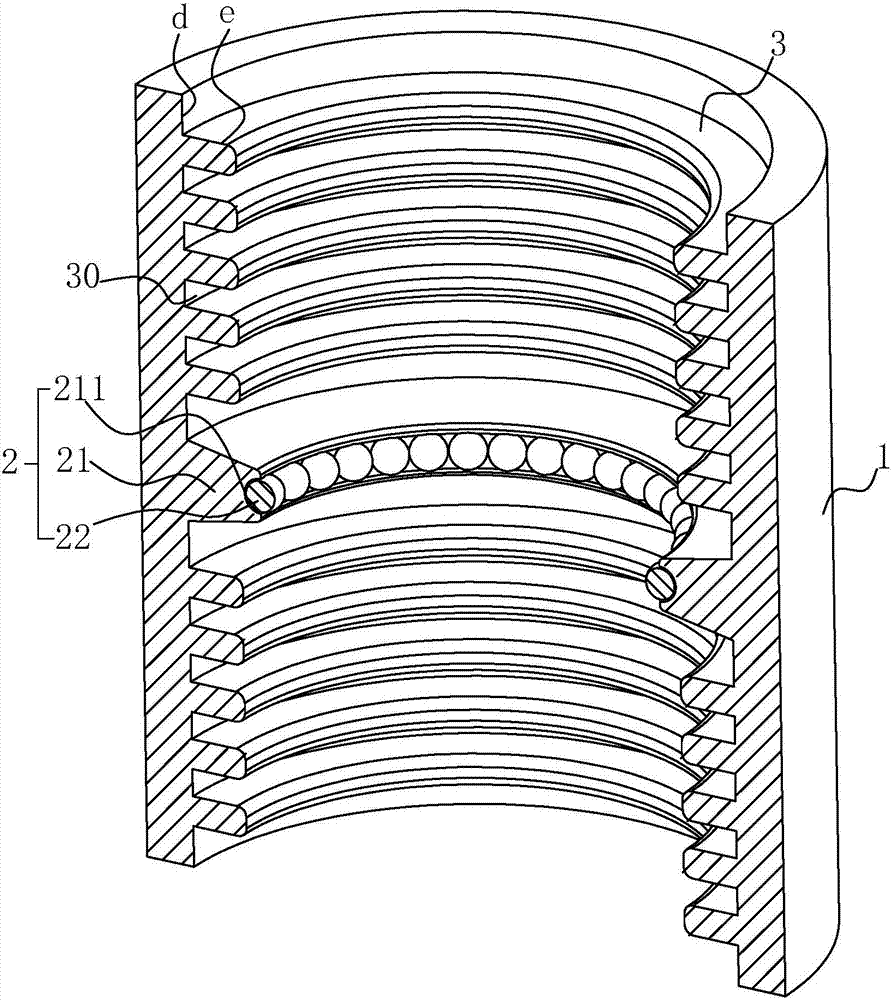

Embodiment 1

[0084] refer to figure 2 with image 3 , an insulating shell with integrated functions, including a cylindrical shell 1, where the "cylindrical" should include but not limited to three-dimensional shapes such as cylinders, spheres, ellipsoids, and spindles. Embodiment 1 uses cylinders The cylindrical shell 1 is an example, the cylindrical shell 1 can be made of glass, ceramics, glass-ceramic or plastic, and the first embodiment uses ceramic material as an example, and the openings at both ends of the cylindrical shell 1 are used to seal the metal cover plate to form a closed vacuum interrupter, figure 1 The arc pilot ring 2 located in the middle of the axial direction of the cylindrical shell 1 can be seen in the figure. The arc pilot ring 2 includes an annular mounting ring 21, and an annular fitting groove 211 is formed on the inner circumference of the mounting ring 21. The fitting groove 211 is used for To fit and connect the ball contacts 22, a plurality of ball contac...

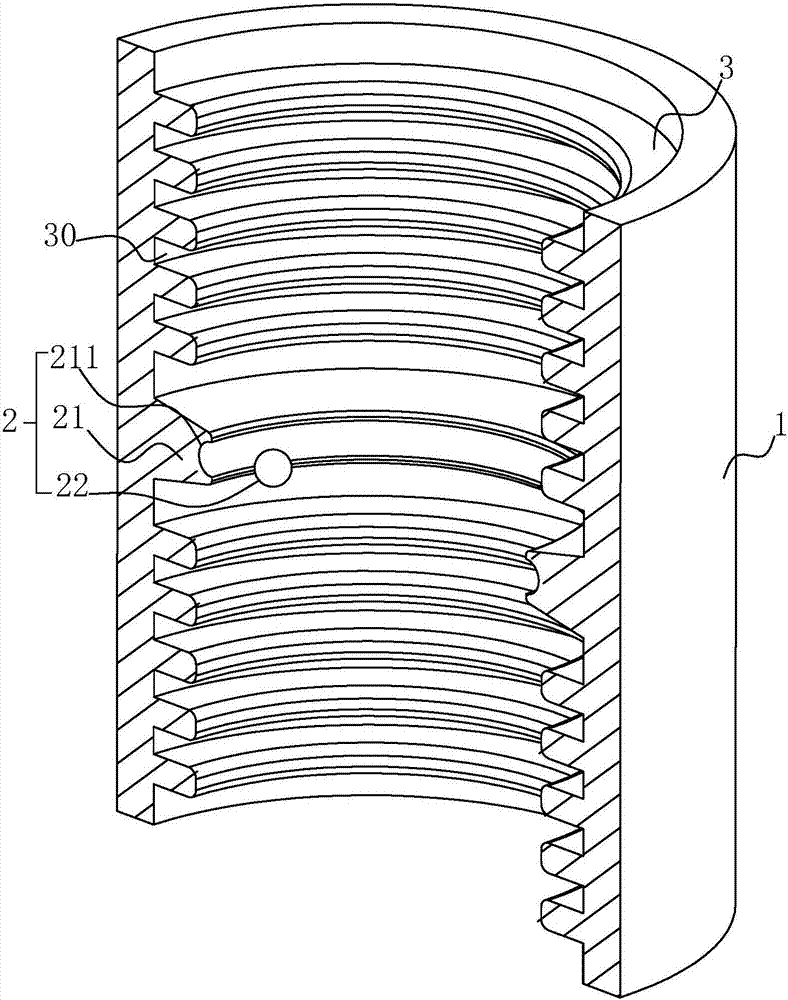

Embodiment 2

[0090] An insulating housing with integrated functions, see Figure 5 , the difference from Embodiment 1 is that the spherical contact 22 is replaced by a columnar contact 23, and the shape selection of the contact on the arc ring 2 for attracting the arc between the contacts should be avoided as much as possible. The burrs or corners are used to reduce the impact of the contacts on the magnetic field in the vacuum interrupter and improve the voltage resistance of the vacuum interrupter. The columnar contact 23 shown in the figure has a longer length in the axial direction of the cylindrical shell 1 Length, suitable for higher voltage vacuum circuit breakers with larger spacing between contacts.

Embodiment 3

[0092] An insulating housing with integrated functions, see Image 6 The difference between it and the second embodiment is that the cylindrical contact 23 is replaced by a ring contact 24. Since the outer diameter of the ring contact 24 matches the diameter of the fitting groove 211, it is difficult to install a complete ring into the fitting Therefore, the circular contact 24 is divided into three or more equal parts, which are installed and welded in the fitting groove 211 one by one to form a complete ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com