Motor flange drill jig

A motor flange and drill die technology, which is applied to the drill die for workpieces and other directions, can solve the problems of inconvenient drill sleeve replacement, complicated operation steps, fixed drill sleeve size, etc., and achieves simple structure, cost reduction, and simple positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

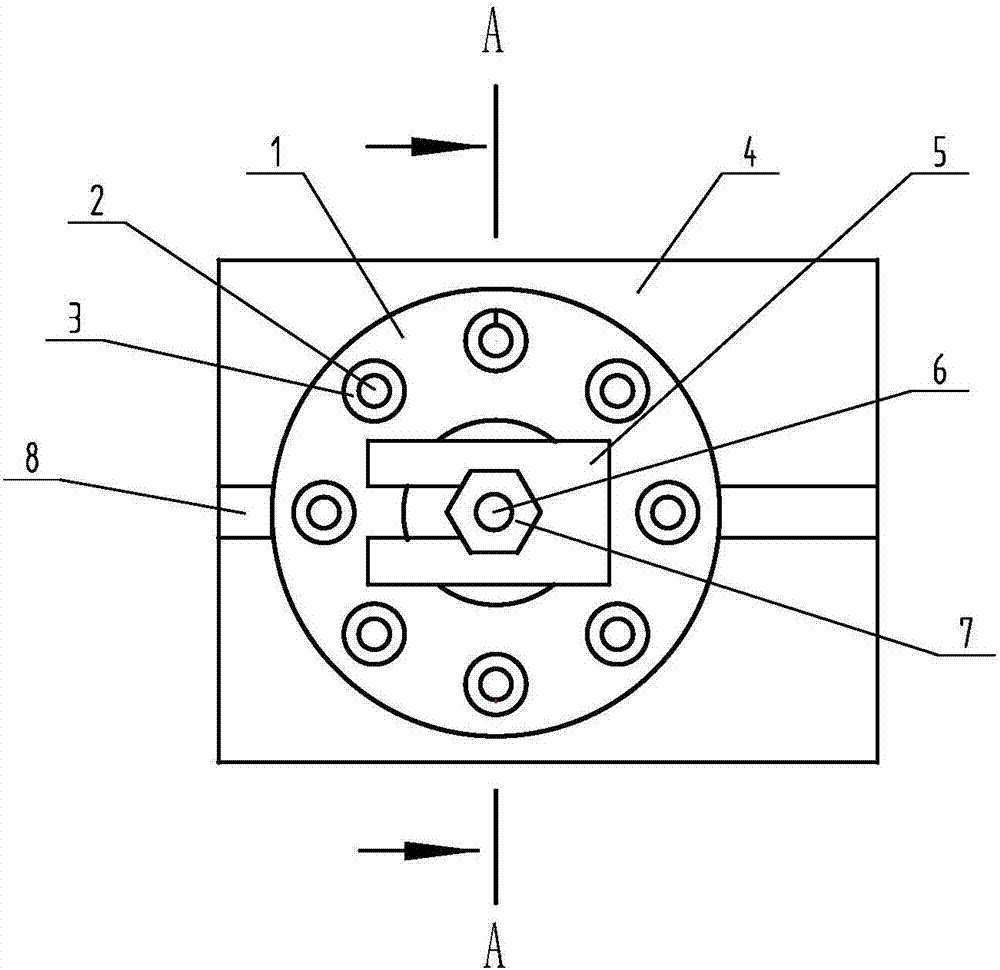

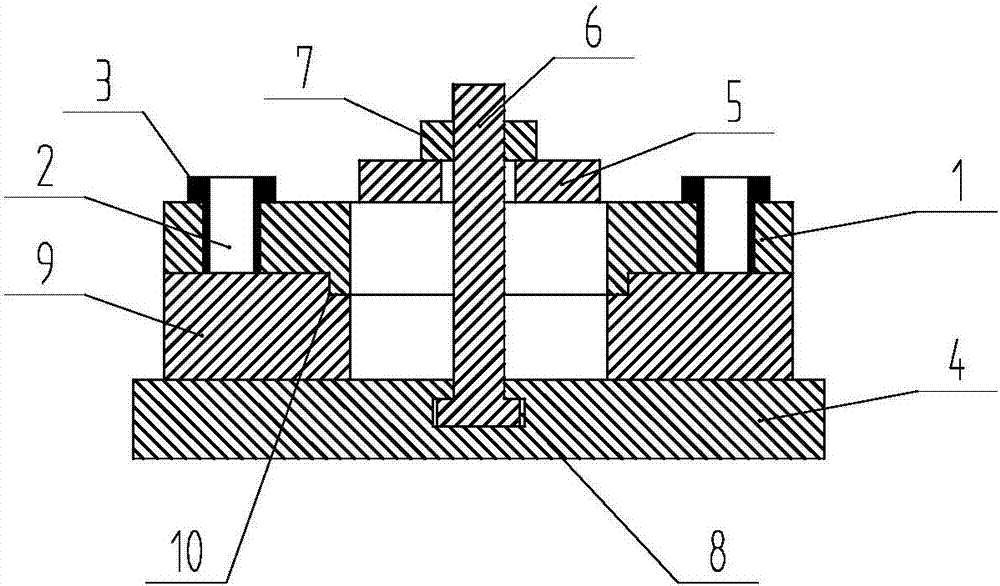

[0019] Such as figure 1 , figure 2 Shown, a kind of motor flange drilling template comprises drilling template 1, locating device and clamping device, and drilling template 1 is circular-shaped, and on the drilling template 1, more than one mold hole 2 is evenly arranged along the same circumference, and mold hole 2 A drill sleeve 3 is sleeved inside, and the clamping device includes a base 4, a U-shaped pressure plate 5, a locking bolt 6 and a locking nut 7. The base 4 is provided with an inverted T-shaped groove 8, and the head of the locking bolt 6 is clamped. In the inverted T-shaped slot 8, and can slide in the inverted T-shaped slot 8, the screw rod of the locking bolt 6 passes through the inner ring of the motor flange 9 placed on the base 4 and the inner ring of the drilling template 1 in sequence from bottom to top With the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com