Engine crankshaft storage rack

A technology for engines and storage racks, which is applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problems of not being able to meet the storage requirements of engine crankshafts of different models, a wide variety of storage racks, and low use efficiency, and achieve high reliability, convenient operation, and The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

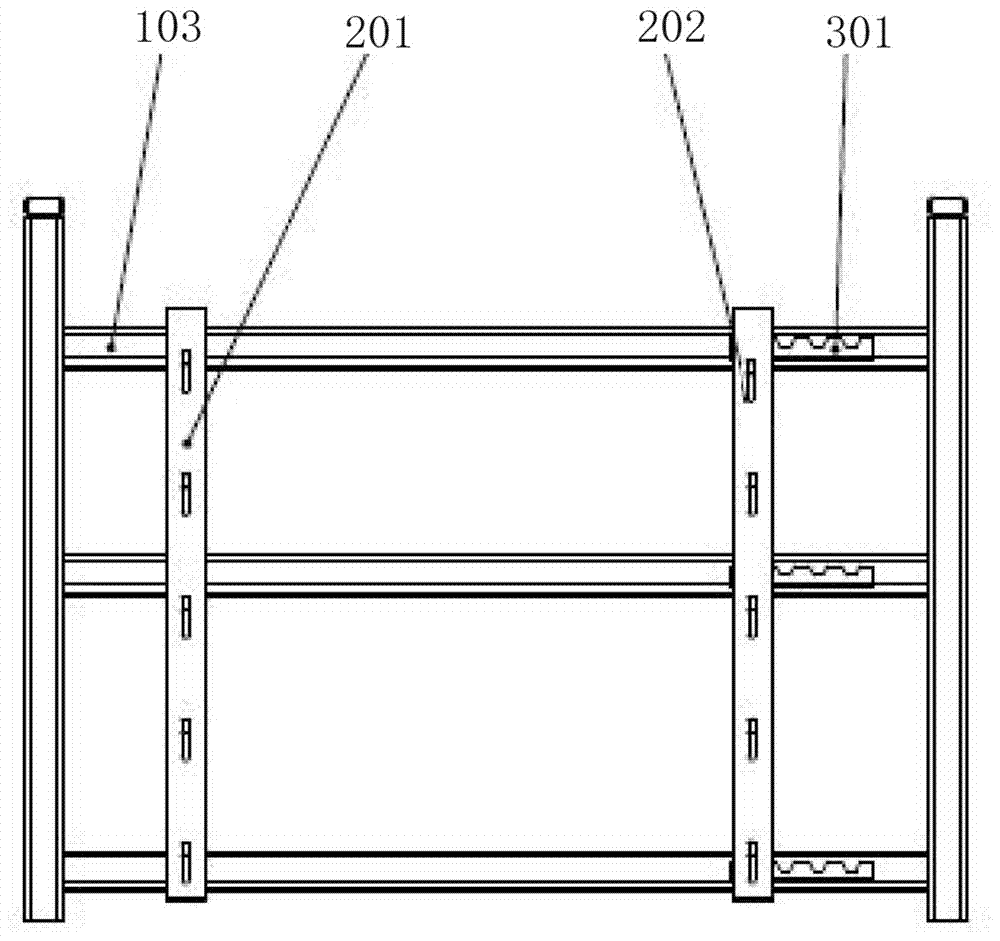

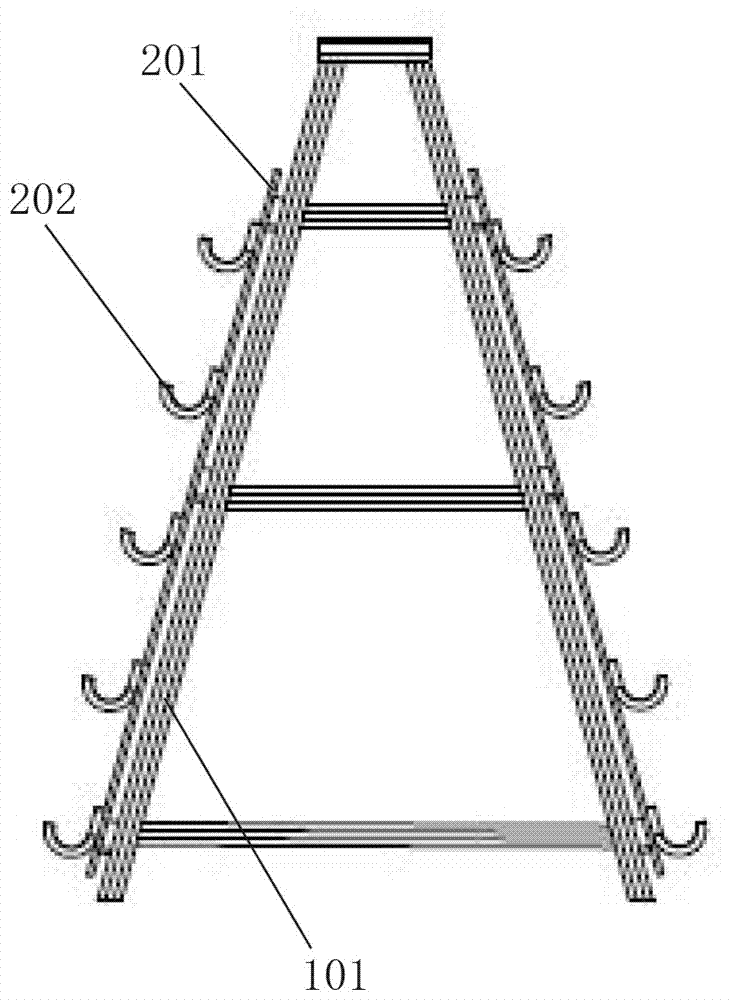

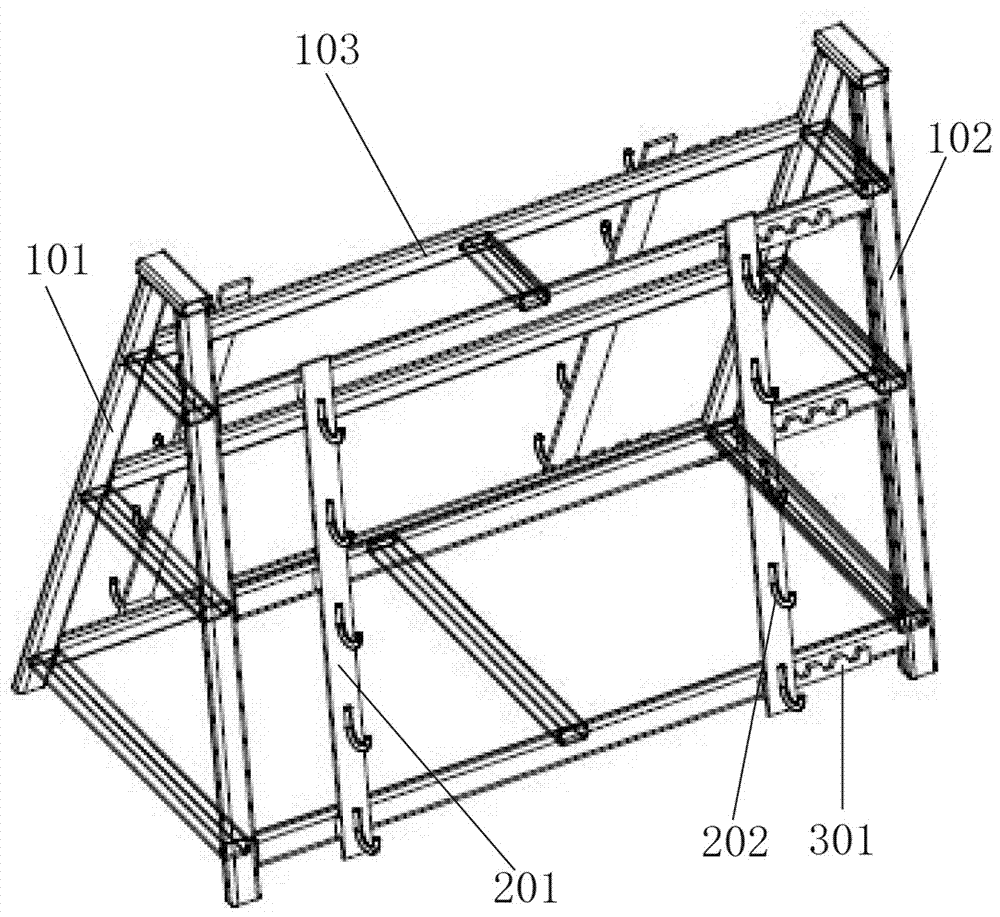

[0020] see Figure 1-Figure 5 , an engine crankshaft storage rack according to the present invention, comprising a left bracket 101 and a right bracket 102, the left bracket 101 and the right bracket 102 are both in a herringbone structure, and the two are arranged correspondingly on the left and right; between the left bracket and the right bracket A plurality of cross braces 103 are arranged at intervals, and the cross braces 103, the left bracket 101 and the right bracket 102 form a support frame; two support brackets 201 are correspondingly arranged on each side of the support frame, and the two supports The bracket 201 is provided with multiple groups of corresponding hooks 202, and the engine crankshaft is matched and placed on the two corresponding hooks 202; at least one of the two support brackets 201 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com