Welding seal adhesive tape and preparation method thereof

A welding sealing and tape technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve problems such as inconvenient operation, and achieve the effect of solving inconvenient operation, protecting the bonding effect and ensuring the welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing the welding sealing tape according to the present invention, comprising the following steps:

[0032] Extrude the raw materials of the base layer, spray hot-melt glue on the surface of the base layer in situ, and cool down to obtain the welding sealing tape.

[0033] Among them, the pressure of the nozzle when spraying hot melt adhesive wire is 2.5-4.5kgf / cm 2 .

Embodiment 1

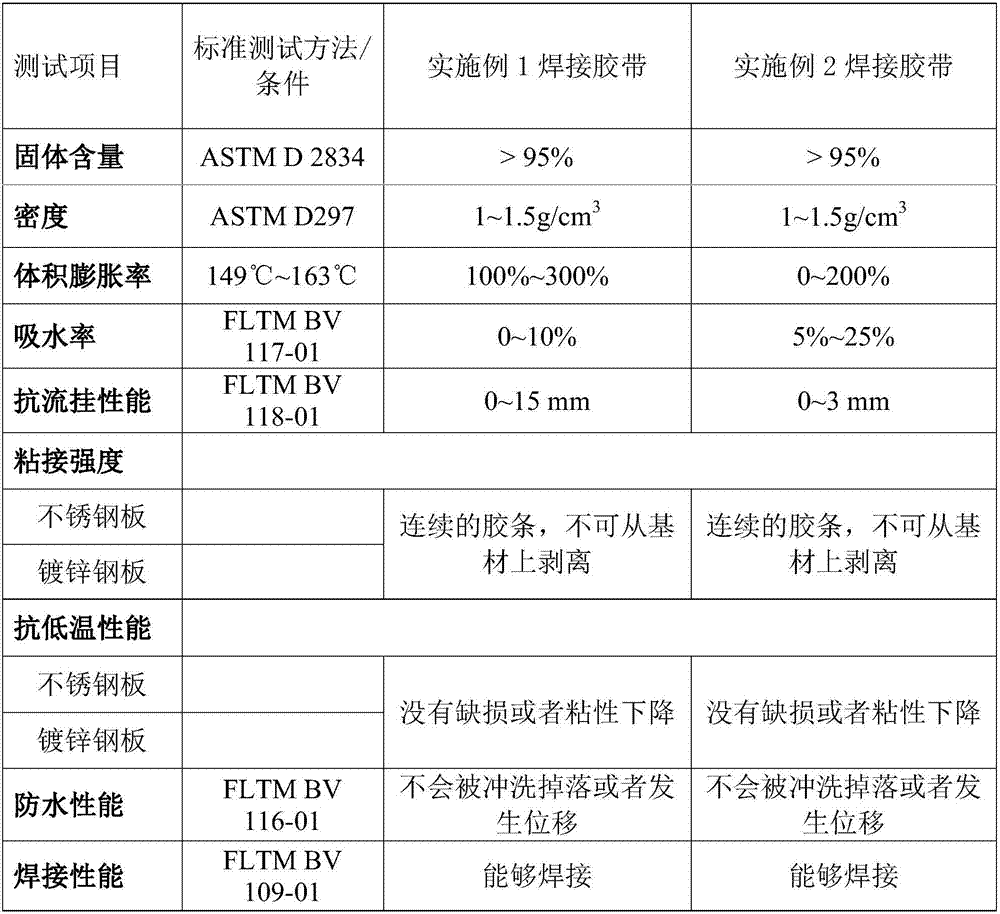

[0037] Use ethylene-vinyl acetate copolymer (EVA) as the base material, extrude EVA into a 1.5mm thick sheet at 110°C, and spray EVA hot-melt glue online at 160°C, where the nozzle pressure is 3.5kgf / cm 2 , Welding sealing tape was obtained after cooling, and the test results are listed in Table 1.

Embodiment 2

[0039] Use EPDM as the base material, extrude EPDM into a 1.3mm thick sheet at 110°C, spray EVA hot-melt glue online at 160°C, and the nozzle pressure is 3.5kgf / cm 2 , Welding sealing tape was obtained after cooling, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com