Copper alloy and method for producing complex special-shaped end face bar

A copper alloy and special-shaped technology, applied in the field of metal materials, can solve problems such as uneven deformation stress and deformation, and achieve the effect of uniform alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

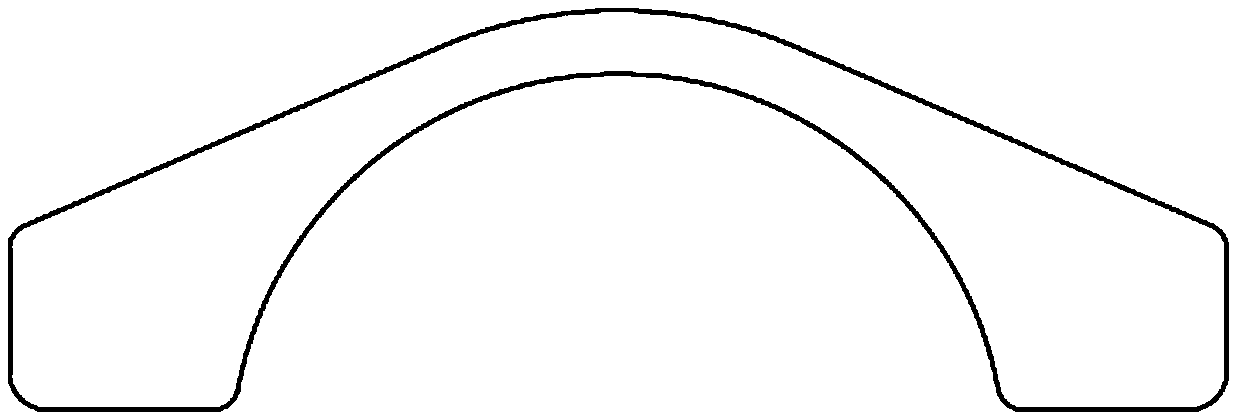

[0029] Curved extruded rods (see figure 1 ) manufacture. The width of the profile is 96mm, and the minimum arc thickness is 5mm. With such an aspect ratio of arc size, it is easy to produce arc deformation, depression, asymmetry, etc. during the hot extrusion process.

[0030] The special-shaped bar production steps are as follows:

[0031] (1) Batching: take scrap copper as raw material, carry out batching according to the elemental composition (see Table 1) of the copper alloy of producing complex special-shaped end face;

[0032] (2) Refining ingot casting: The configuration of melting furnace + refining furnace + heat preservation casting furnace is adopted. The refining furnace is connected to the melting furnace and heat preservation furnace through a diversion groove. The melt is diverted to the refining furnace through the diversion groove for refining. It is refined at 1020-1120°C by combining boiling physical methods and chemical flux refining. During the refining ...

Embodiment 2

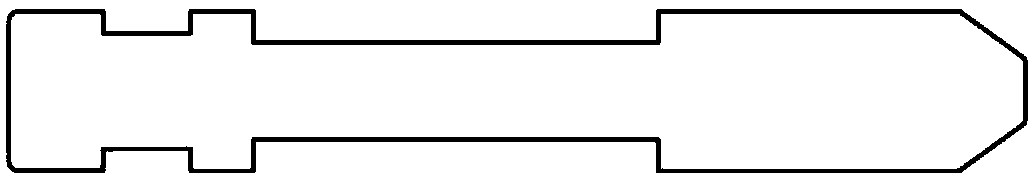

[0036] Flat processed materials (see figure 2 ) manufacture. The product is characterized by wide, flat and complex shapes. The width is 25mm, the minimum thickness is 2.4mm, the symmetrical surface has six parallel surfaces, the two sides of the edge are asymmetrical, and one end has a tapered flat head, the minimum size is only 1.6mm, and the dimensional accuracy is high. This is a processed product, which requires material removal and local plastic deformation to ensure its shape and accuracy. The processing process is most prone to uneven and twisted problems. Alloy materials need to have a blank with good machinability and plasticity, and the resistance is small when planing. , When the deformation is small, the production can be smooth.

[0037] The difference between the production method of the flat processed material in this embodiment and that of Example 1 is: (1) the element composition of the copper alloy is different (see Table 1); (2) the extrusion die pass de...

Embodiment 3

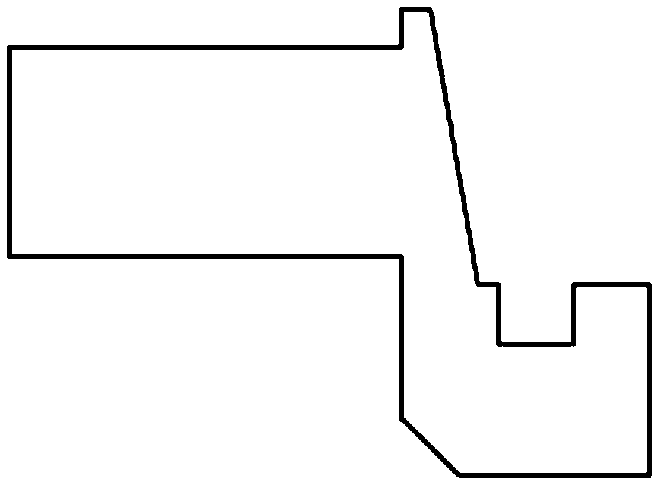

[0039] Shaped rods for instrument brackets (see image 3 ) manufacture. Mainly used for instrument brackets. After the downstream manufacturing of this product is interrupted, there is no need to process the shape, the efficiency is improved, and the material utilization rate is improved. The shape of this product is characterized by small edges, slopes and grooves. The key to production is to ensure size, smoothness, no defects, and no cracks.

[0040] The difference between the production method of the special-shaped bar for the instrument bracket in the present embodiment and the embodiment 1 is: (1) the elemental composition of the copper alloy is different (see Table 1); (2) the ingot extrudes the near-net blank, The head is driven by automatic control of limit, centering and jacking, and the head is directly produced, and the finished product is produced by planing and shaping. The products produced by this process method meet the application requirements, and the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com