Guideway for trailers used for coal mining

A guide rail and trailer technology, which is applied in the field of trailer guide rails, can solve the problems of high maintenance cost and easy bending deformation, and achieve the effects of reducing maintenance costs, improving support stability, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

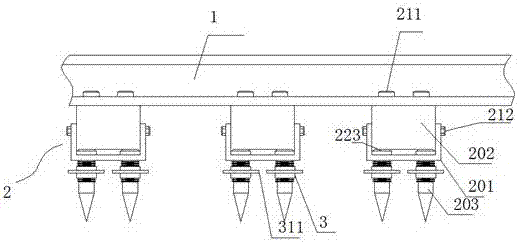

[0012] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

[0013] see figure 1 The shown trailer guide rail for coal mine development includes a guide rail body 1, and a support assembly 2 supported under the guide rail body 1. The support assembly 2 includes a U-shaped base 201 and is fixed on the base 201. The sleeper 202 inside, and the insertion rod 203 fixed in the base 201 and passing through the base 201, a screw 211 is matched between the sleeper 202 and the guide rail body 1, and the insertion rod 203 has External thread, the insertion rod 203 is connected with a limit sleeve 3 through the external thread, the limit sleeve 3 is provided with a limit piece 311 outside, and the limit piece 311...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com