Method for measuring dynamic liquid surface of oil well with frequency difference infrasonic wave generator

A technology of infrasonic wave and generator, which is applied in the field of oil and gas field development, can solve the problems of signal strength depletion, uncontrollable infrasonic wave, discontinuity, etc., and achieve the effect of low operation cost and construction intensity, more precise reflection wave position, and definite reflection wave position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The operating method of the present invention will be discussed in detail below in conjunction with the accompanying drawings.

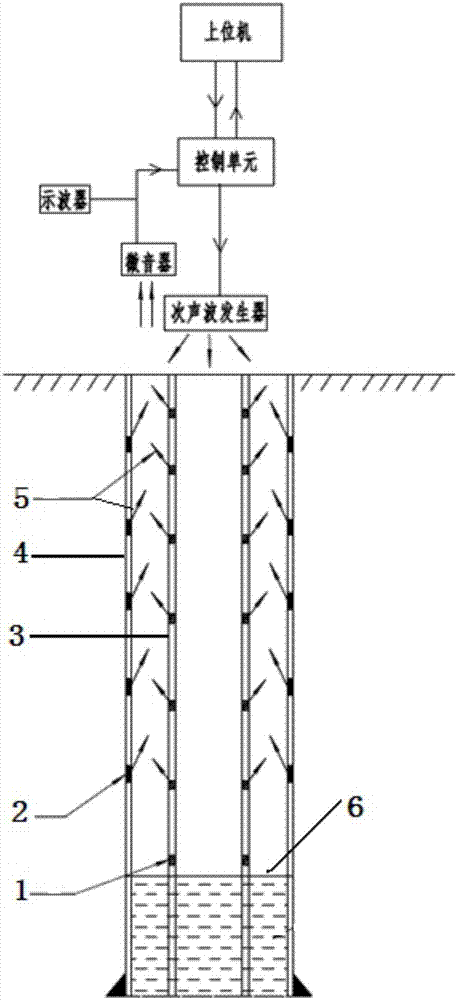

[0027] Such as figure 1 As shown, a method for measuring the dynamic liquid level of an oil well with a frequency difference type infrasonic generator comprises the following steps:

[0028] (1) Pre-installed echo

[0029] During casing and tubing operations in oil wells, a casing echo 2 is installed on the inside of each casing collar, and a tubing echo 1 is pre-installed on the outside of each tubing collar, and the echo is used as a reflector of infrasonic waves at the wellhead , can accurately measure the position of the coupling;

[0030] (2) Install frequency difference infrasonic generator

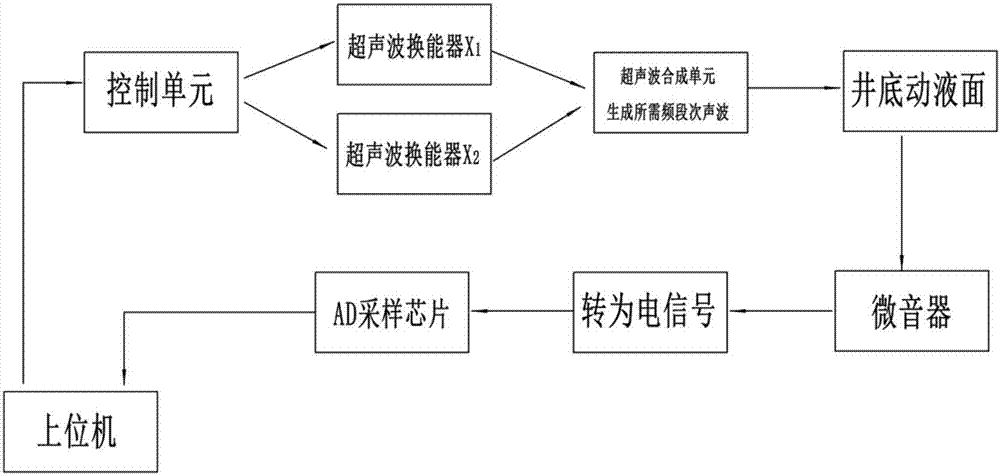

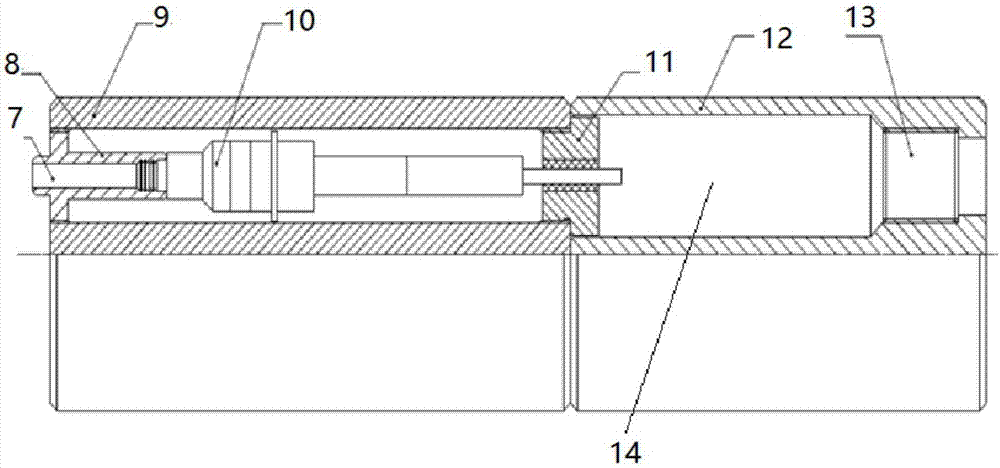

[0031] see Figure 4 The frequency difference infrasonic generator is installed above the wellhead and connected to the control unit. The control unit is connected to the microphone at the wellhead and the remote host computer and oscilloscope r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap