Detection method for quick estimation based on inherent frequency of damaged beam

A technology of natural frequency and detection method, applied in the field of detection based on the rapid estimation of the natural frequency of damaged beams, can solve the problem that the complexity is not easily accepted by enterprise engineers, and achieve the effect of overcoming the complexity of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

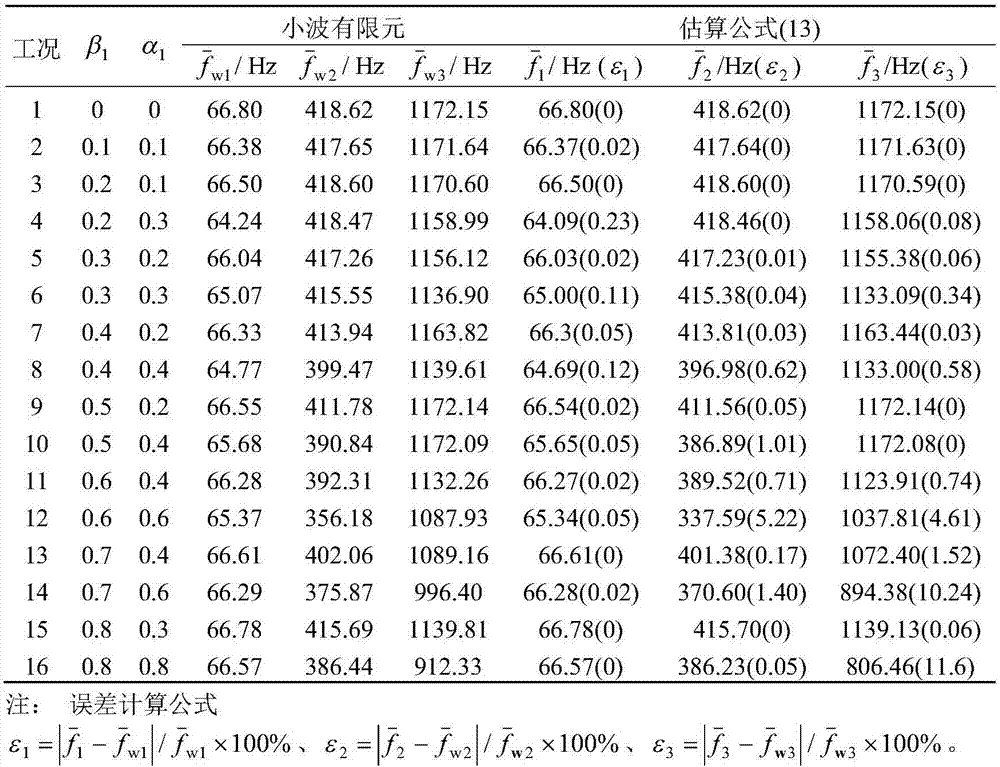

[0084] Implementation case 1: In order to verify the effectiveness of the natural frequency estimation formula (13) of the damaged beam structure in the method of the present invention for single damage, the frequency estimation of the cantilever rectangular section beam structure with single damage in this implementation case and high-precision wavelet finite element calculation results Comparing the results with Figure 4 shown. The calculation parameters are as follows: beam length L=0.5m, elastic modulus E=2.1×10 11 N / m 2 , beam height h=0.02m, beam width b=0.012m, Poisson’s ratio μ=0.3, material density ρ=7860kg / m 3 . Figure 4 In addition to case 12(α 1 =0.6), 14(α 1 =0.6) and 16(α 1 =0.8), the third-order natural frequency of single-damage cantilever beam structural frequency estimation is in good agreement with the high-precision wavelet finite element calculation results. In an actual beam structure, if the relative degree of damage reaches 0.5, the structur...

Embodiment example 2

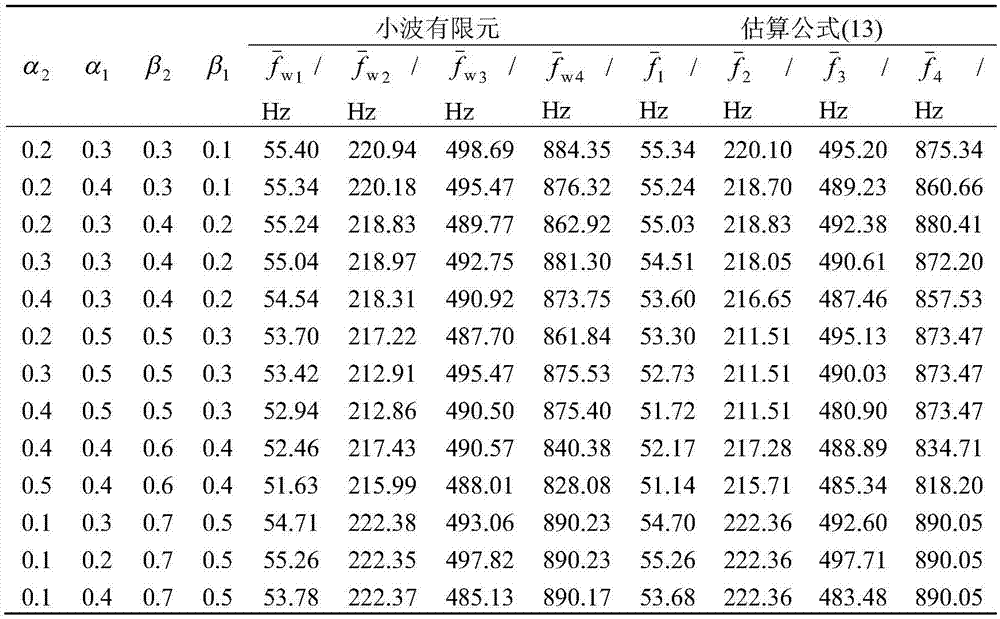

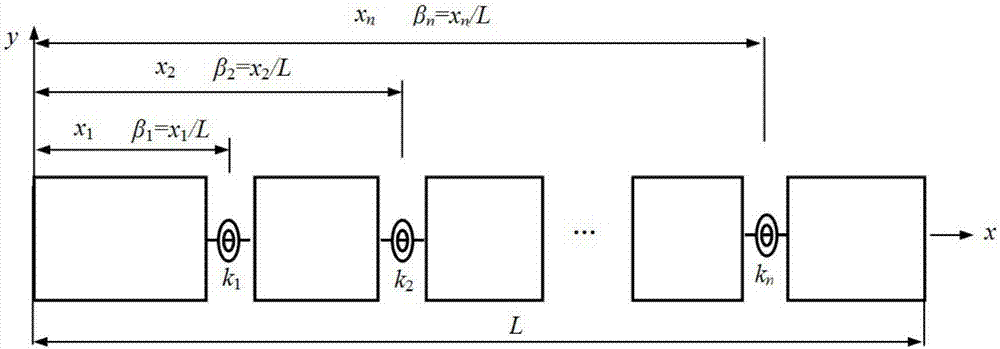

[0085] Implementation case 2: In order to verify the validity of the natural frequency estimation formula (13) of damaged beam structures in the method of the present invention to multiple damages, the frequency estimation of two damaged circular cross-section simply supported beam structures in this implementation case and high-precision wavelet finite element calculation results Comparing the results with Figure 5 shown. Calculation parameters are as follows: beam length L=0.85m, modulus of elasticity E=2.06×10 11 N / m 2 , circular section radius r 1 =0.01m, Poisson's ratio μ=0.3, material density ρ=7860kg / m 3 . The fourth-order natural frequencies estimated by the frequency estimation of two damaged circular cross-section simply supported beams are in good agreement with the high-precision wavelet finite element calculation results. Therefore, the natural frequency estimation formula (13) can be used to quickly estimate the frequency of multi-damage beam structure...

Embodiment example 3

[0086] Implementation case 3: In order to verify the effectiveness of the detection method based on the rapid estimation of the natural frequency of the damaged beam in this invention, this implementation case conducts detection based on the method of the invention for two actual damaged rectangular cross-section cantilever beam structures. The geometric parameters of the beam structure are as follows: beam length L=0.5m, beam height h=0.019m, beam width b=0.012m. Elastic modulus E=2.06×10 11 N / m 2 , Poisson's ratio μ=0.3, material density ρ=7860kg / m 3 . There are two damages on the beam structure, and the relative position of the damage is: β 1 =0.16, β 2 =0.76, the relative degree of damage is: α 1 =0.42, α 2 = 0.42. Hammer-excited modal experiments such as image 3 As shown, for the actual two cantilever beam structures with damaged rectangular section, the sampling frequency f s =5000Hz, the number of sampling points is 10000, while the beam structure is being str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com