Winding-type cell

A winding type battery technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of waste of separator 3, reduce the energy density of batteries, increase the thickness of batteries, etc., to save costs and realize automation The effect of production and energy density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The wound battery core of the present invention will be described in detail below with reference to the accompanying drawings.

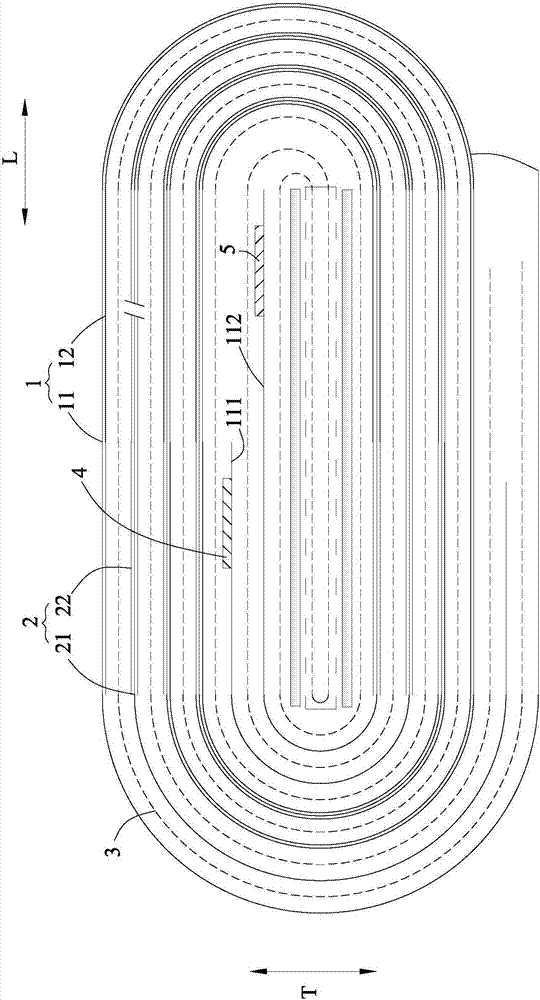

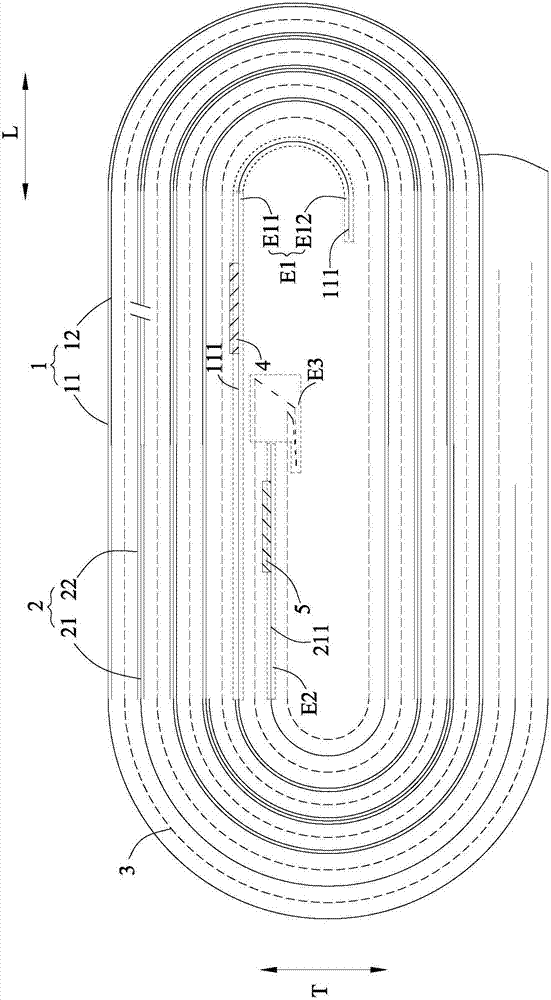

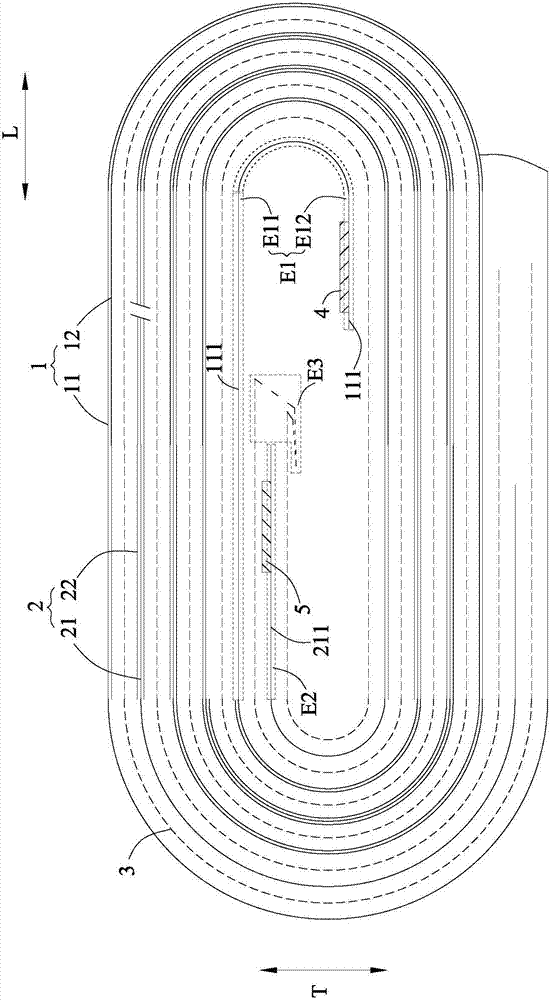

[0030] refer to Figure 2 to Figure 5 , according to the present invention, the winding type electric core comprises: a first pole piece 1 having a first current collector 11 and a first active material layer 12 coated on at least one surface of the first current collector 11; a second pole piece 2 , has a second current collector 21 and a second active material layer 22 coated on at least one surface of the second current collector 21, and the second winding start segment E2 of the second pole piece 2 has an uncoated second active material The blank second current collector 211 of the layer 22; the isolation film 3 is arranged between the first pole piece 1 and the second pole piece 2, so as to isolate the first pole piece 1 and the second pole piece 2; the first pole piece 4, electrically connected to the first current collector 11; the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com