Short-distance branch terminal tightening and automatic locking strained tensioner

A technology of branch lines and tighteners, applied in the direction of overhead lines/cable equipment, etc., can solve the problem that branch wires cannot be completed at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

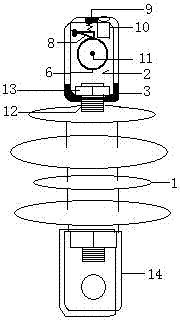

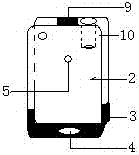

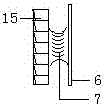

[0010] attached figure 1 shows the structure of the present invention, the figure 1 The top of terminal tension insulator 1 is provided with terminal locking tensioner 2, the bottom of terminal locking tensioner 2 is provided with first reinforced tension plate 3, and the bottom of first reinforced tensioner 3 is set at the middle position figure 2 Threading hole 4, pin hole 5 is set in the middle of the front, and pin hole 5 is set inside image 3 Tension ratchet 6, anti-slip ribs 7 are set on the winding shaft surface in the middle of the tension ratchet 6, and the top of the tension ratchet 6 is set figure 1 Ratchet pawl 8, figure 1 A second reinforced tension plate 9 is arranged at the middle position on the top of the terminal lock tightening device 2, and a three-jaw clamp 10 with inverted tooth pattern inside is arranged at one end of the second reinforced tension plate 9.

[0011] The assembling process of the present invention is: at first will image 3 Tension r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com