Cooling mold frame

A formwork and cooling fan technology, applied in the field of casting, can solve the problems of large floor area and serious environmental pollution, achieve good mechanical properties, and reduce the effect of cooling floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

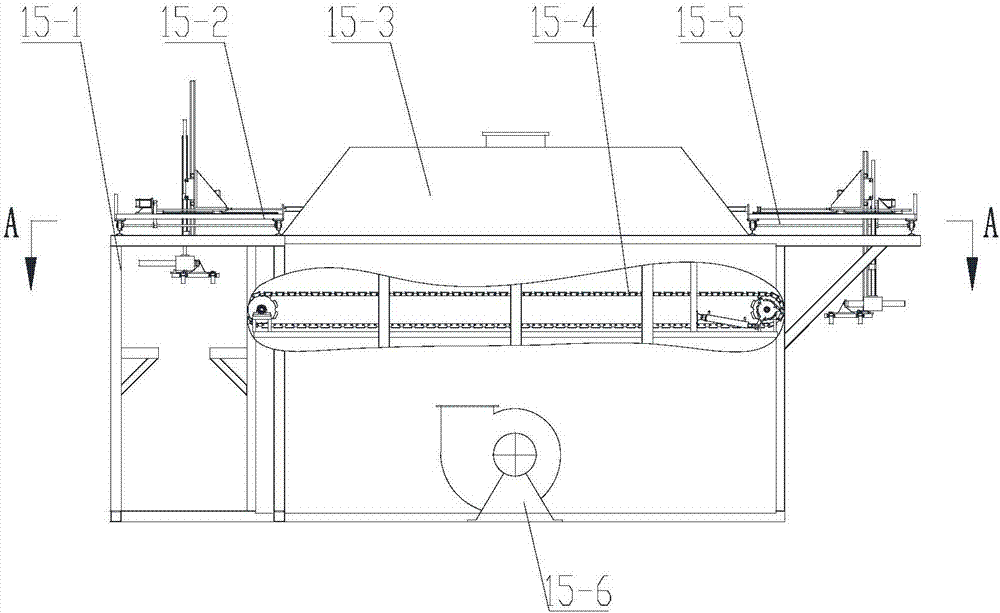

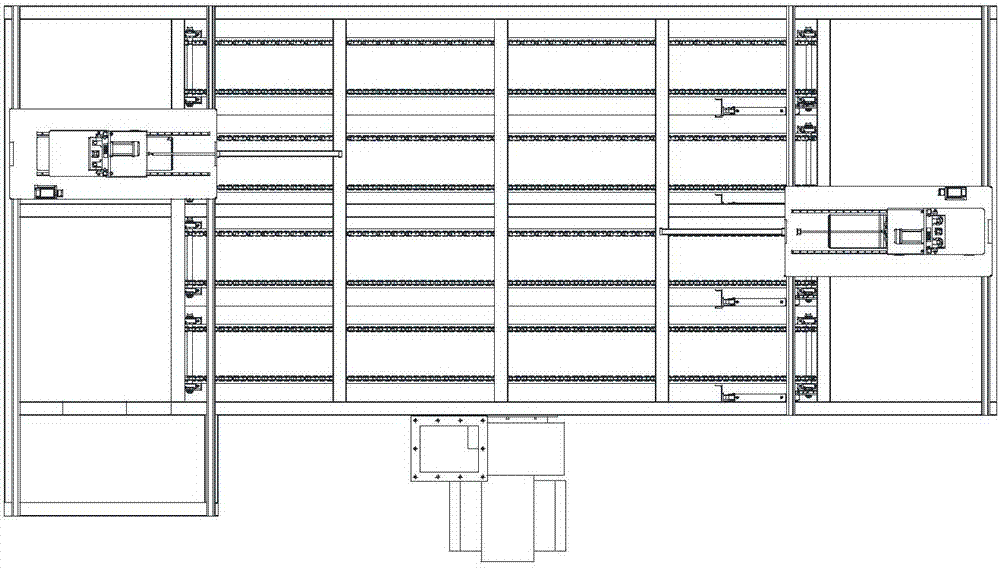

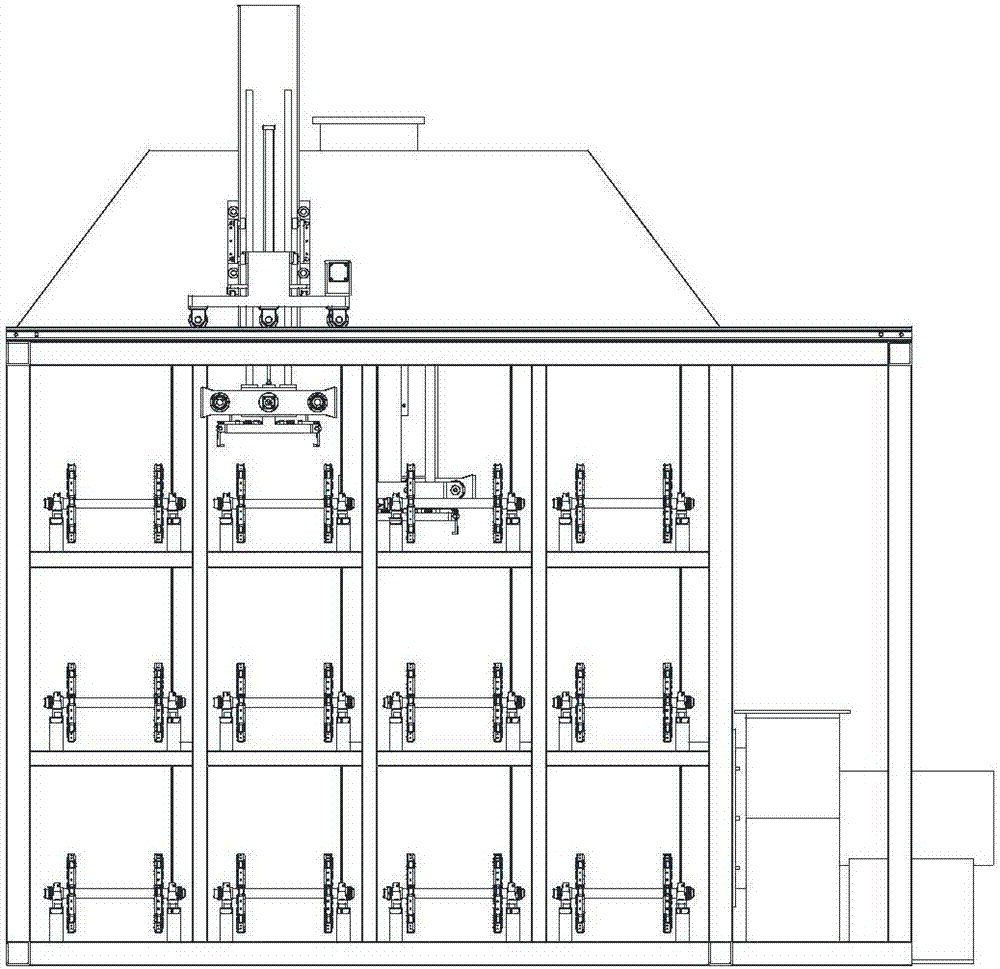

[0030] Present embodiment cooling formwork ( Figure 1-4 ) includes cooling mold frame frame 15-1, cooling mold frame input manipulator 15-2, cooling dust removal system (including suction hood 15-3, cooling fan 15-6), conveyor chain 15-4, cooling mold frame output Box manipulator 15-5, etc., the box-in side of frame 15-1 is installed into box manipulator 15-2, the box-out side is installed with box-out manipulator 15-5, the interior is installed with conveyor chain 15-4, and the top is installed with suction cover 15- 3. Cooling fans 15-6 are installed outside.

[0031] The cooling formwork frame 15-1 is made of square steel, has 3 layers in total, and each layer has 4 entry positions, and each case position is equipped with a conveyor chain 15-4 in the horizontal direction, and each conveyor chain Can place 9 sand boxes. The front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com