Integrated waterway module and water purifying device

An integrated waterway and waterway technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increasing the weight of the whole machine, low assembly reliability, and low molding reliability. Achieve the effect of improving installation efficiency, convenient installation and production, and avoiding hidden dangers of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following combination Attached The present invention will be further described by showing the examples.

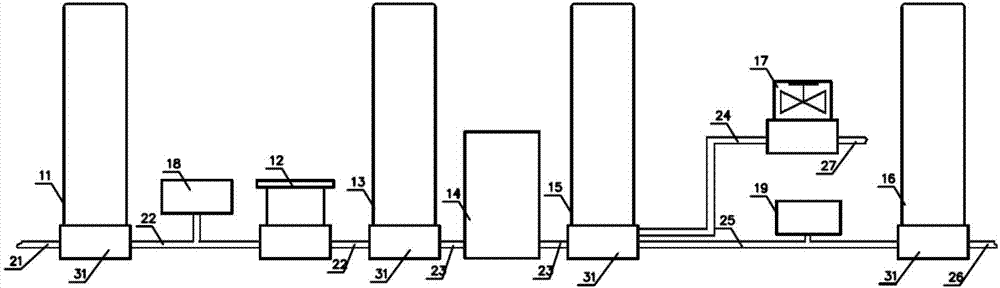

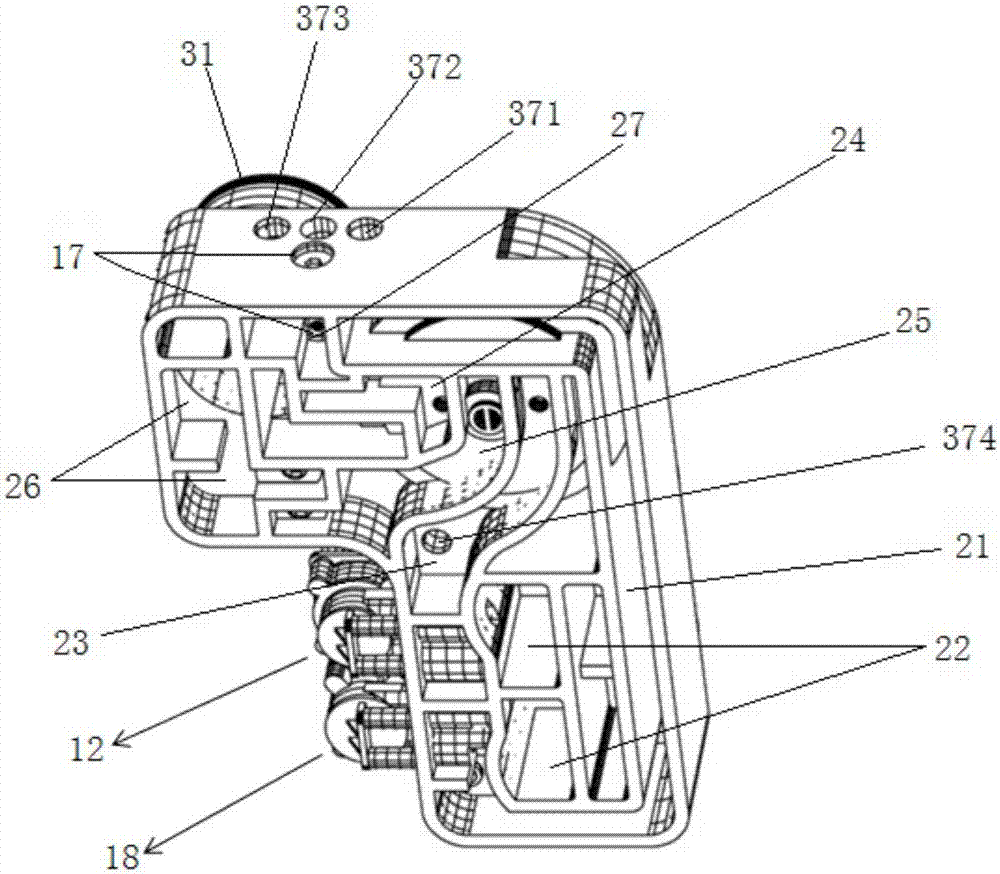

[0029] picture 1 For the water purification equipment connection arrangement principle of the present invention picture , which includes a first-stage filter element 11, a water inlet solenoid valve 12, a first-stage filter element 13, a booster device 14, a third-stage filter element 15, and a post-filter element 16;

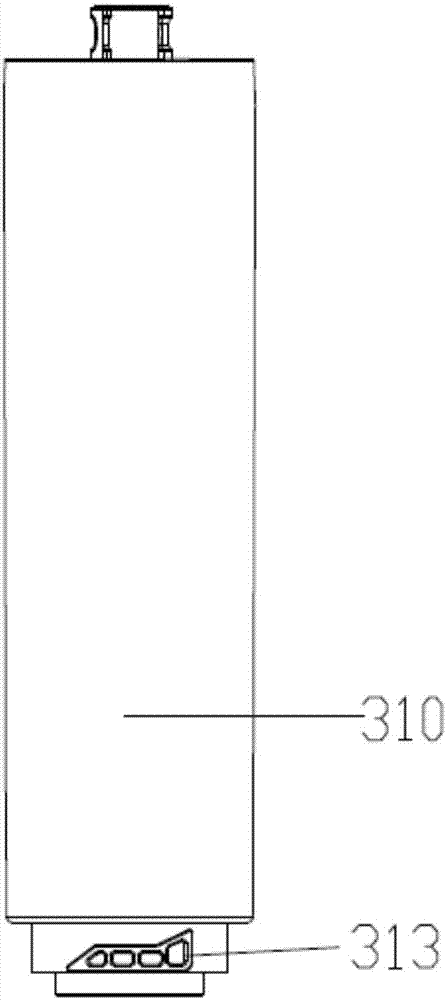

[0030] The first stage filter element 11 is arranged on the first stage filter element seat 111; the second stage filter element 13 is arranged on the second stage filter element seat 131; the third stage filter element 15 is arranged on the third stage filter element seat 151; The filter element 16 is arranged on the rear filter element seat 161; it also includes the following parts:

[0031] The raw water flow channel 21 is formed by connecting pipeline components and pipeline joints. The inlet end of the raw water flow channel 21 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com