Double-sided type anti-sliding cement speed reducer cover with baffle block

An anti-skid belt, double-sided technology, applied in mechanical equipment, belts/chains/gears, transmission parts, etc., can solve problems such as insufficient connection, failure of reducer, and easy detachment of reinforcing ribs, so as to improve work efficiency. , prolong the service life, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

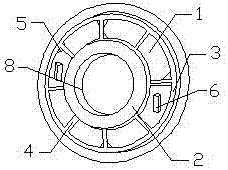

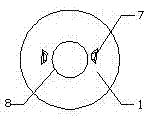

[0018] see figure 1 and figure 2 , the present invention is a double-sided non-slip cement reducer cover with stoppers, which includes a reducer cover body 1, the reducer cover body 1 is in the shape of a ring, and the surface of the reducer cover body 1 is provided with different Adhesive layer, the front of the reducer cover body 1 is respectively provided with an inner flange 2 and an outer flange 3 from the inside to the outside, and the inner flange 2 and the outer flange 3 are all in the shape of a ring, and the inner flange 2 and the outer flange 3, and on the reducer cover body 1, there is at least one block 6, and the inner flange 2 and the outer flange 3 are connected by at least two reinforcing ribs 4, each of which A connector 5 is provided at the connection between the rib 4 and the inner flange 2 or the outer flange 3; the back of the reducer body 1 is provided with a handle 7, and the surface of the inner flange 2 is provided with an anti-skid layer 8, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com