Automatic roll replacing device

An automatic detection device technology, applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of high safety hazard, high labor intensity, long time, etc., to reduce operation intensity, high degree of automation, The effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

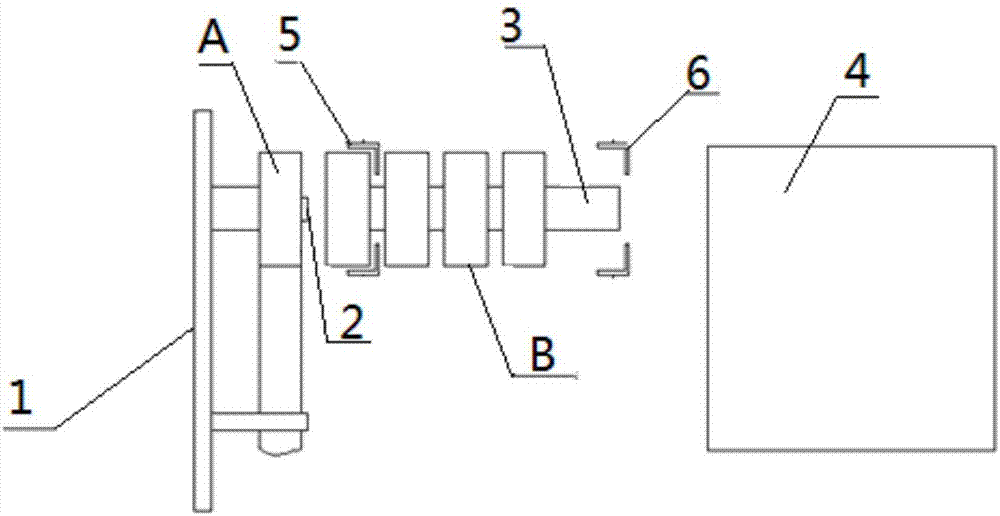

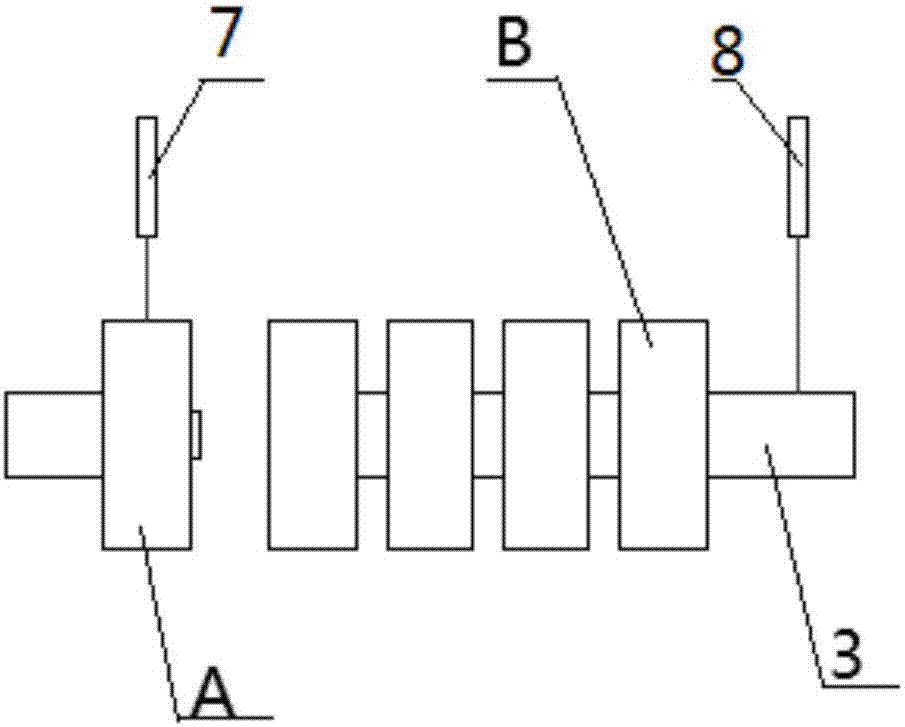

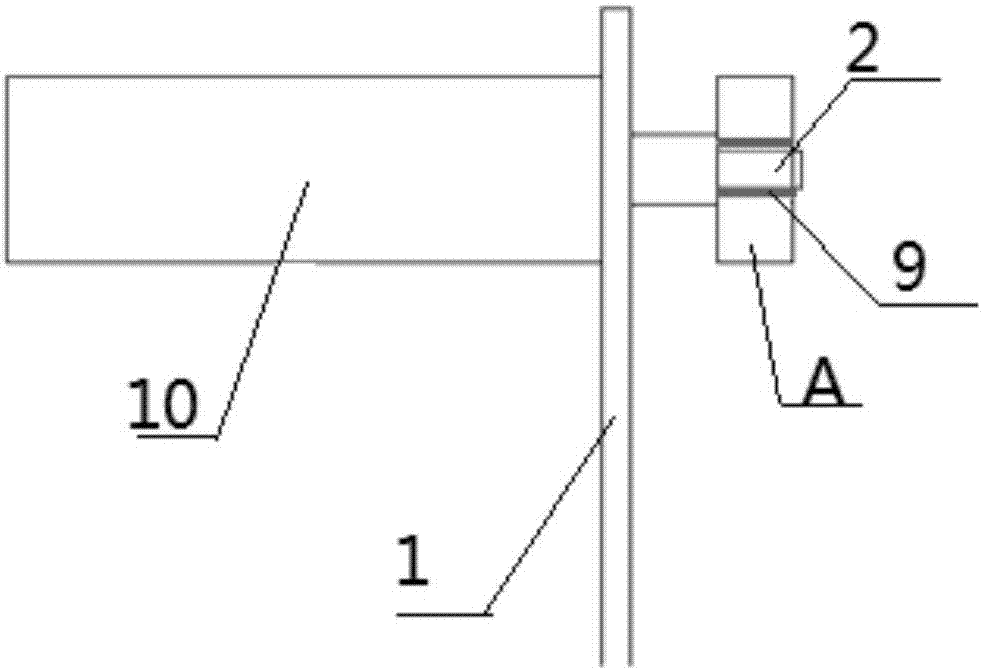

[0021] refer to figure 1 , an automatic roll changing device proposed by the present invention, comprising: a vertical plate 1, a roll support shaft 2, a guide post 3, a roll frame 4, a feeding manipulator 5, a pushing manipulator, a reclaiming manipulator 6, a first detection Device 7, second detection device 8 and control module.

[0022] The vertical plate 1 serves as a supporting mechanism and provides a unified installation plane and installation reference for the installation of other mechanisms. In this embodiment, the surface of the vertical board is coated or oxidized to fully eliminate stress, and the flatness of the vertical board installation is controlled at 0.02mm.

[0023] The roll support shaft 2 is a telescopic structure, and it is horizontally installed on the vertical plate 1 . The material roll support shaft 2 is used to fix the material roll A in the extended state, and is used to unload the material roll A in the contracted state. In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com