Plate type aerating spreading device capable of automatic cleaning

An automatic cleaning and diffusion device technology, applied in the direction of sustainable biological treatment, water aeration, special treatment goals, etc., can solve the problems of affecting the aeration effect and blockage of aeration diffusion parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

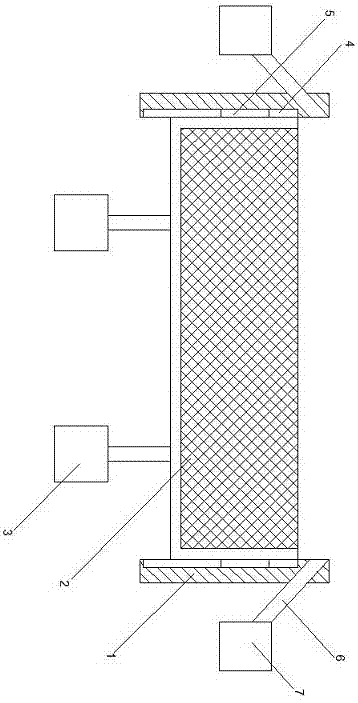

[0014] like figure 1 A plate type aeration diffusion device that can realize automatic cleaning treatment is shown, which includes a diffusion frame 1, and a diffusion packing layer 2 arranged inside the diffusion frame 1; the lower end surface of the diffusion packing layer 2 is connected with a plurality of The lifting motor 3 arranged outside the diffusion frame, a plurality of lifting tanks 4 are arranged on the inner wall of the diffusion frame 1, a plurality of lifting end bodies 5 are arranged on the side end surface of the diffusion packing layer 2, and a plurality of The lifting end body 5 and the plurality of lifting tanks 4 correspond to each other one by one, and each lifting end body 5 extends into the corresponding lifting tank body 4;

[0015] As an improvement of the present invention, at least four lifting motors 3 are arranged on the lower end surface of the diffusion packing layer 2, which are evenly distributed along the edge of the diffusion packing layer....

Embodiment 2

[0018] As an improvement of the present invention, auxiliary cleaning pipes 6 are arranged on both sides of the diffusion frame 1, which are connected to the air compressor 7 arranged outside the diffusion frame 1, and each auxiliary cleaning pipe 6 is provided by the diffusion frame The outer wall of the diffusion frame 1 extends obliquely upwards into the inner wall of the diffusion frame 1. Adopting the above-mentioned technical scheme, it can carry out airflow output treatment on the upper end of the diffusion packing layer through the setting of the auxiliary cleaning pipeline, so that the dirt that sinks and floats to the corresponding position of the diffusion packing layer can be floated under the action of the above-mentioned air flow to avoid its sedimentation To the inner area of the diffusion packing layer to cause blockage.

[0019] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0021] As an improvement of the present invention, the distance between the upper end of the auxiliary cleaning pipeline 6 and the upper end of the diffusion frame 1 is at most 1 centimeter, which can make the airflow output by the auxiliary cleaning pipeline clean the dirt on the upper end of the diffusion packing layer. The effect can be further improved.

[0022] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com