Composite material laminated board and preparation method thereof

A composite material layer and joint technology, which is applied in the field of composite material laminates and its preparation, shopping mall shelves and storage goods, can solve the problems of variability and damage, paint is not environmentally friendly, load-bearing and easy to deform, and achieve high promotion value , good fire performance, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

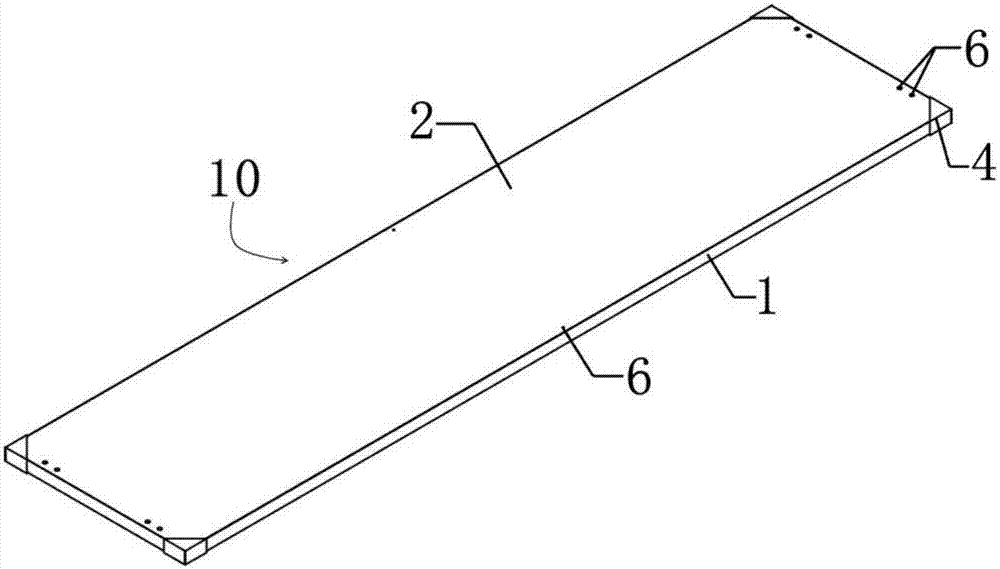

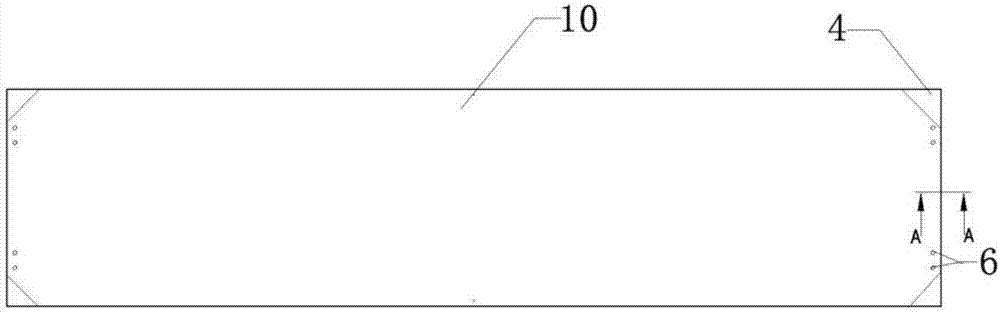

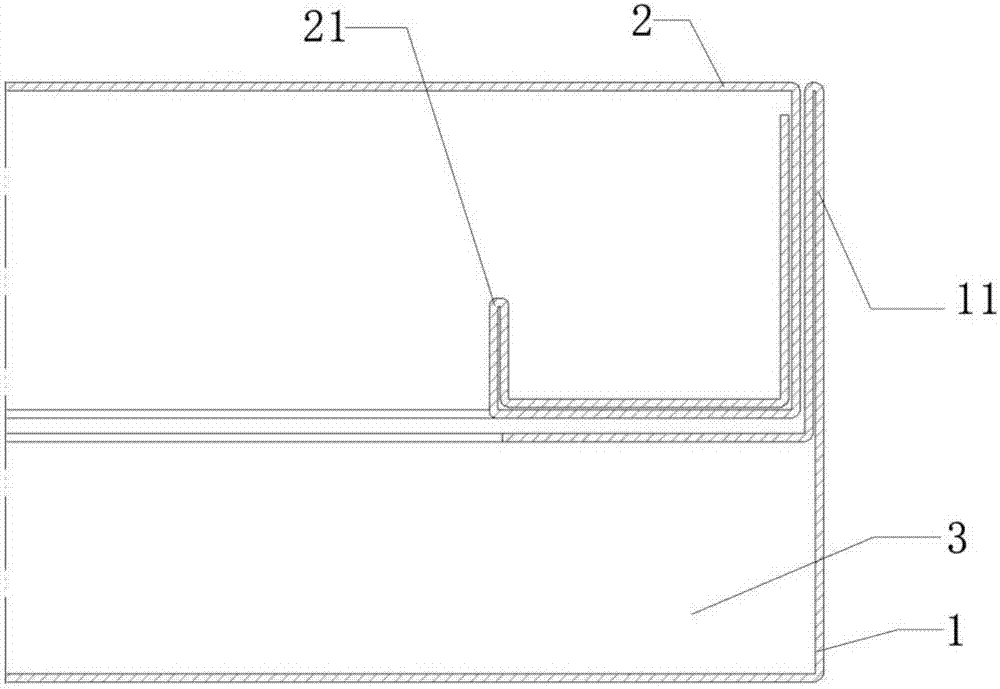

[0036] Such as Figure 1-2 The composite material laminate shown includes a laminate body 10 , and the laminate body 10 includes an outer bent iron box 1 , an inner bent iron box 2 and a filling layer 3 . Wherein, the outer bending iron box 1 and the inner bending iron box 2 are made of coated iron, and the coated iron includes an iron layer and a PVC film layer, and the iron layer and the PVC film layer are laminated together, The filling layer 3 is a polyurethane filling layer 3 . Such as image 3 As shown, the edge of the outer bending iron box 1 is provided with an outer bending 11, and the edge of the inner bending iron box 2 is provided with an inner bending 21, and the outer bending iron box 1 and the inner bending iron box 2 They are buckled together, and a filling layer 3 is provided between the outer bent iron box 1 and the inner bent iron box 2 . Moreover, corner protectors 4 are provided on the four corners of the laminate body 10 . Among them, such as Figure...

Embodiment 2

[0038] Such as Figure 1-2 The composite material laminate shown includes a laminate body 10, and the laminate body 10 includes an outer bent iron box 1, an inner bent iron box 2 and a filling layer 3, wherein the outer bent iron box 1 and The inner bending iron box 2 is made of coated iron, and the coated iron includes an iron layer and a PVC film layer, and the iron layer and the PVC film layer are laminated together. The filling layer 3 includes the following components in terms of weight components: Component A: 0.8 parts of polyether polyol, 0.1 part of silicone oil, 0.2 parts of diethanolamine, 2 parts of ethylene glycol, 0.2 parts of water, 5 parts of cyclopentane Parts; B component: 0.8 parts of isocyanate. Such as image 3As shown, the edge of the outer bending iron box 1 is provided with an outer bending 11, and the edge of the inner bending iron box 2 is provided with an inner bending 21, and the outer bending iron box 1 and the inner bending iron box 2 They are ...

Embodiment 3

[0048] Such as Figure 1-2 The composite material laminate shown includes a laminate body 10, and the laminate body 10 includes an outer bent iron box 1, an inner bent iron box 2 and a filling layer 3, wherein the outer bent iron box 1 and The inner bending iron box 2 is made of coated iron, and the coated iron includes an iron layer and a PVC film layer, and the iron layer and the PVC film layer are laminated together. The filling layer 3 includes the following components in terms of weight components: Component A: 1.2 parts of polyether polyol, 0.5 parts of silicone oil, 4.5 parts of diethanolamine, 8 parts of ethylene glycol, 3 parts of water, 20 parts of cyclopentane Parts; B component: 1.3 parts of isocyanate. Such as image 3 As shown, the edge of the outer bending iron box 1 is provided with an outer bending 11, and the edge of the inner bending iron box 2 is provided with an inner bending 21, and the outer bending iron box 1 and the inner bending iron box 2 They are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com