End-groping basin

A technology of Suoxu pot and silkworm cocoon, which is applied in the field of Suoxu pot, can solve the problems of aggravating the uneven cooking of cocoons, poor penetration uniformity, and failure to achieve uniform cooking, so as to ensure contact, improve quality, and improve the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

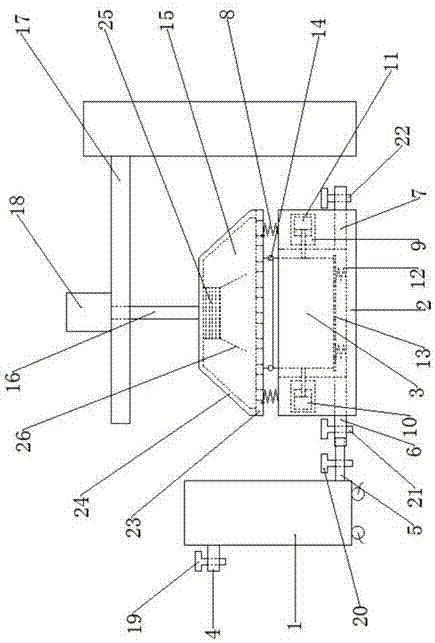

[0028] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0029] In order to achieve the above object, the present invention adopts the following technical solutions: a Suoxu pot, comprising a Suoxu soup storage tank 1, a Suoxu pot body 2 and a silkworm cocoon frame 3, the top side wall and the bottom surface of the silkworm cocoon frame 3 are reticular;

[0030] The Suoxu soup storage tank 1 is provided with a first liquid inlet pipe 4 and a first liquid outlet pipe 5;

[0031]The Suoxu pot body is provided with a second liquid inlet pipe 6 and a second liquid outlet pipe 7, and the second liquid inlet pipe 6 and the first liquid outlet pipe 5 are connected by threads; the Suoxu pot body 2 has two Top elastic bodies 8 are arranged on the side walls, and a traversing mechanism 9 is respectively arranged inside the two side walls, and a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com