Composite driving pipe robot based on fluid and motor

A pipeline robot and driving mechanism technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of insufficient driving force, increased frictional resistance, and limited robot travel, and achieve the effect of large driving force and long travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

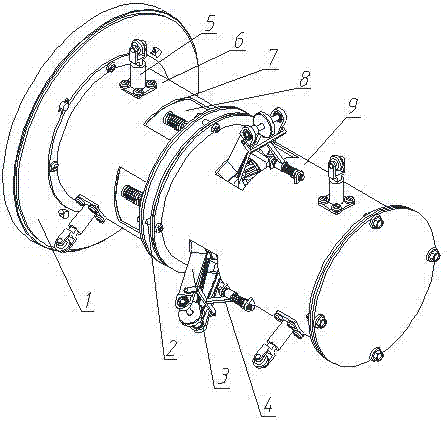

[0026] Such as figure 1 As shown, the present invention mainly consists of a cup mechanism (1), cylinder I (6), throttling mechanism (8), support wheel frame (5), bolt (2), motor drive mechanism (3), coordination mechanism ( 4) and other parts; the bolt (2) connects the flange plate of the cylinder body I (6) and the cylinder body II (9); the cylinder body II (9) has a sealed cavity inside, and is fixed with a motor (14), a battery (15 ) and motor controller (13).

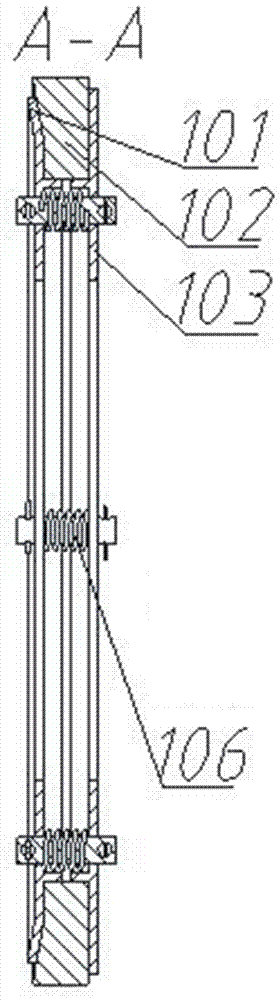

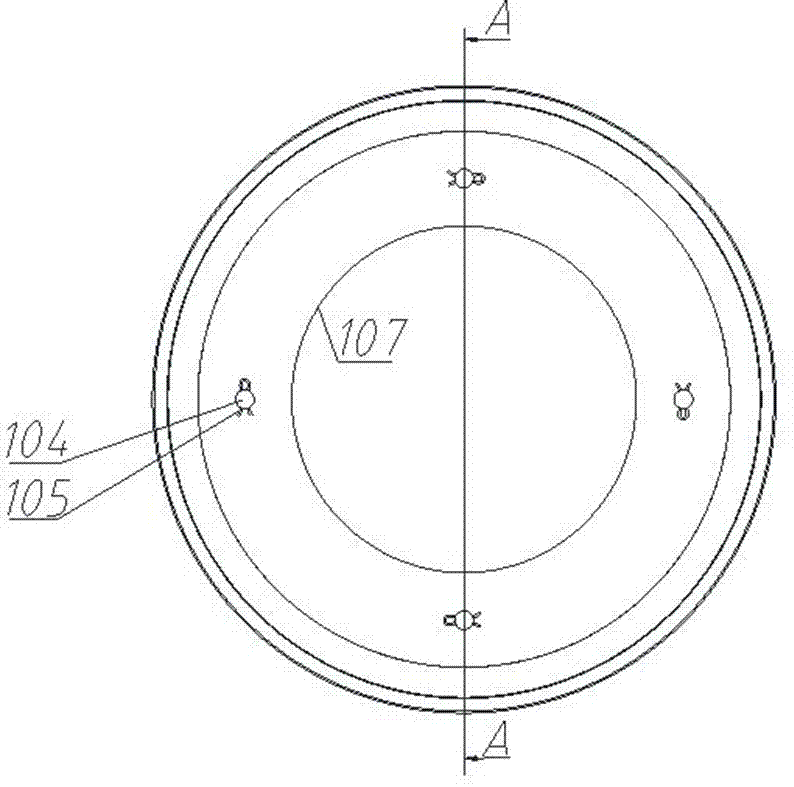

[0027] Such as figure 1 , figure 2 and image 3 As shown, the leather cup mechanism (1) is fixed on the end of the cylinder body I (6), and the leather cup mechanism (1) is mainly composed of a leather cup (102), splint I (101), splint II (103), pins ( 104), cotter pin (105) and pre-tension spring (106), the splint I (101) and splint II (103) are connected by pins (104), and the outside of the two plates is limited by the cotter pin (105) , the pin is covered with a pre-tension spring (106), and the cup (102)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com