Device for testing breaking tenacity in long and narrow space and using method of device

A fracture toughness, in-space technology, used in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., to achieve the effect of simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

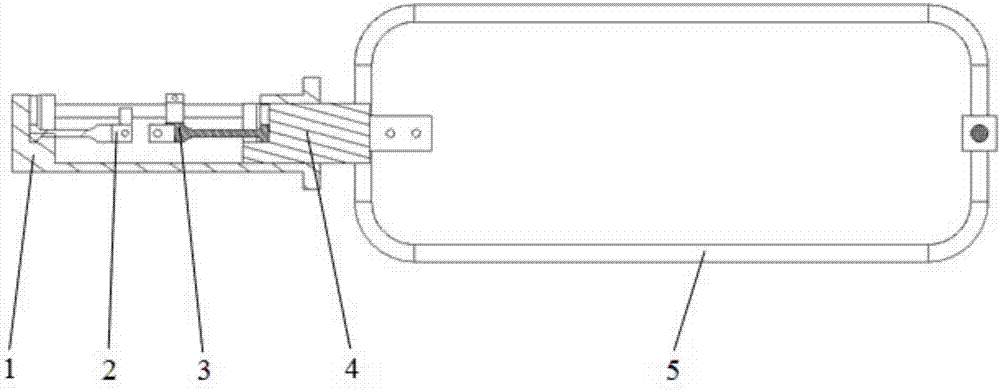

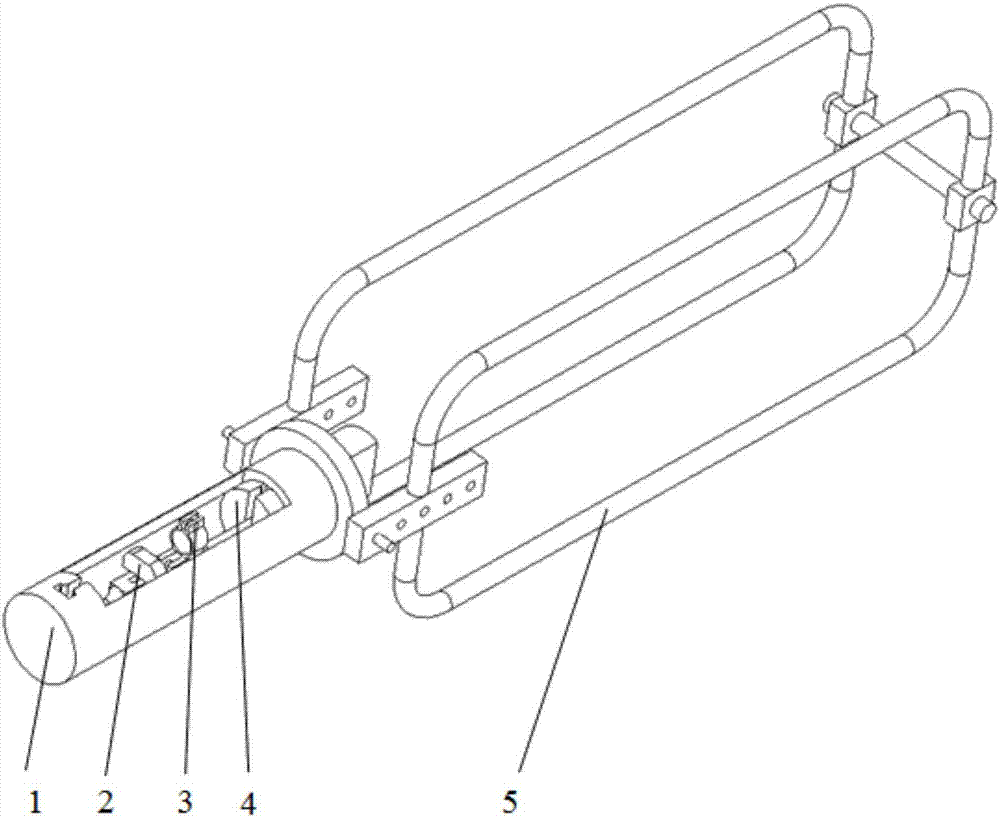

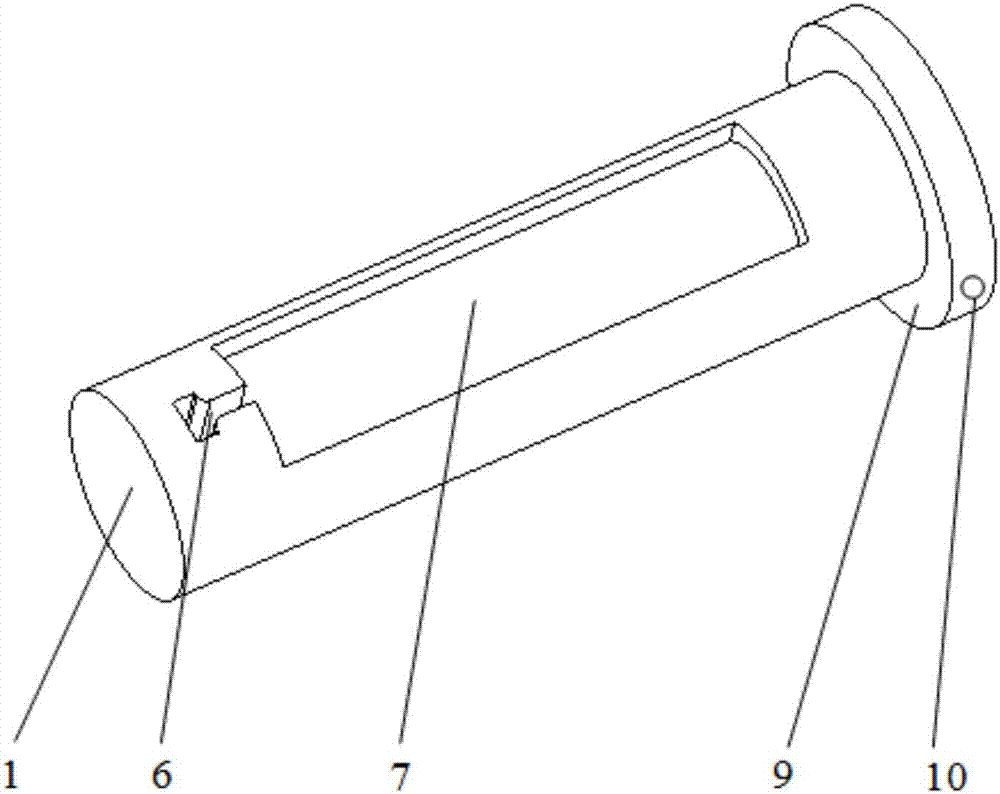

[0037] Such as figure 1 , figure 2 As shown, a device for fracture toughness testing in a long and narrow space is characterized in that it includes a sleeve 1, a left chuck 2 installed inside the sleeve 1, a right chuck 3 and a slider 4, and a Push rod fixing rod 5 other than 1; as image 3 As shown, the middle part of the sleeve 1 is provided with a functional window 7, the tail end is provided with a sleeve slot 6, the front end is provided with a sleeve thick wall 9, and the outer surface of the sleeve thick wall 9 is provided with a sleeve pin hole 10; as Figure 6 As shown, the front end of the slider 4 is provided with a slider slot 17, and its upper end is provided with a horizontal slot 18 and a vertical slot 19, the horizontal slot 18 and the vertical slot 19 are T-shaped as a whole, and the tail end There are threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com