Method for identifying absolute stress of steel component based on transverse wave spectrum analysis

A technology of frequency spectrum analysis and identification method, which is applied in the field of absolute stress identification of steel components, can solve the problems of high sampling rate of sampling equipment, limited application, and high-frequency noise influence of test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

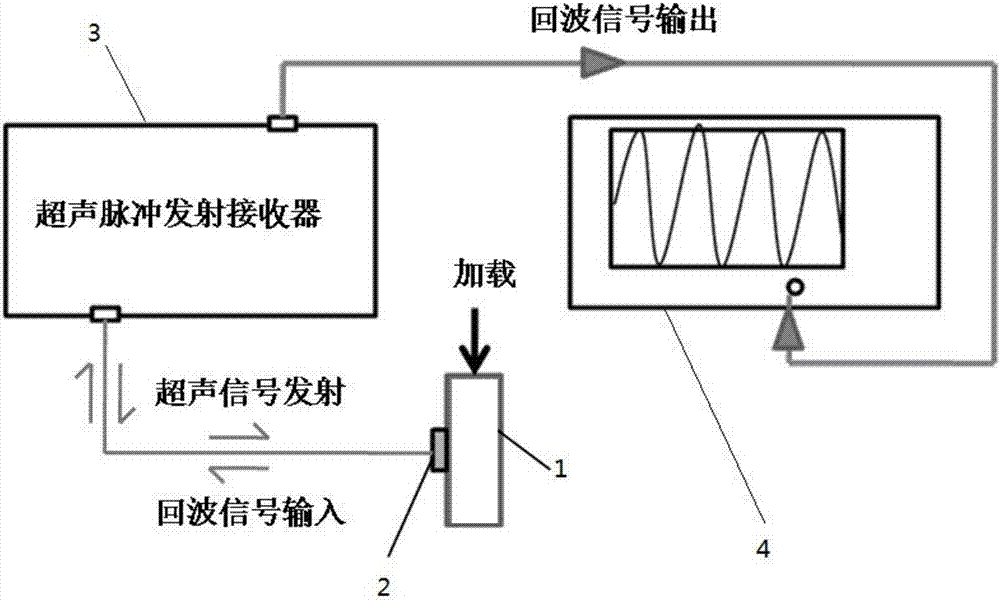

[0043] Embodiment 1 Test method of the present invention and relevant principle explanation

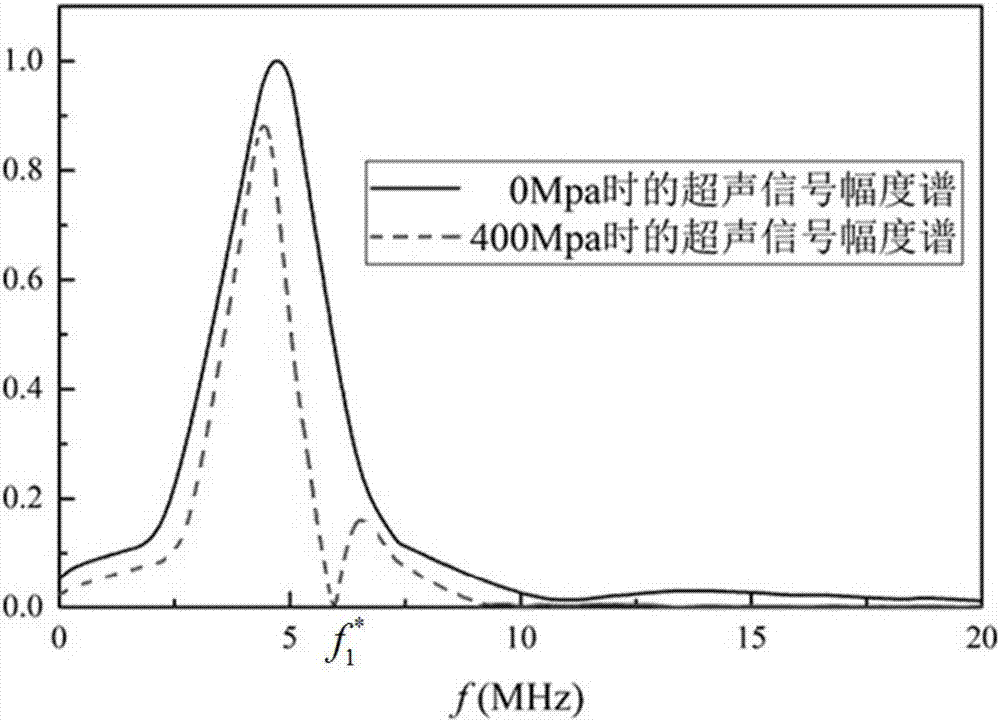

[0044] The principle of the absolute stress identification method of steel members based on shear wave spectrum analysis is as follows.

[0045] When absolute stress exists in the steel member under test, the stress induces acoustic anisotropy of the material. When a beam of shear wave propagates along the direction perpendicular to the stress, the shear wave can be decomposed into two wave components, among which, the wave component whose polarization direction is parallel to the stress direction and the wave component whose polarization direction is perpendicular to the stress direction have different propagation speeds, this phenomenon It is called birefringence, and it is a phenomenon unique to transverse waves.

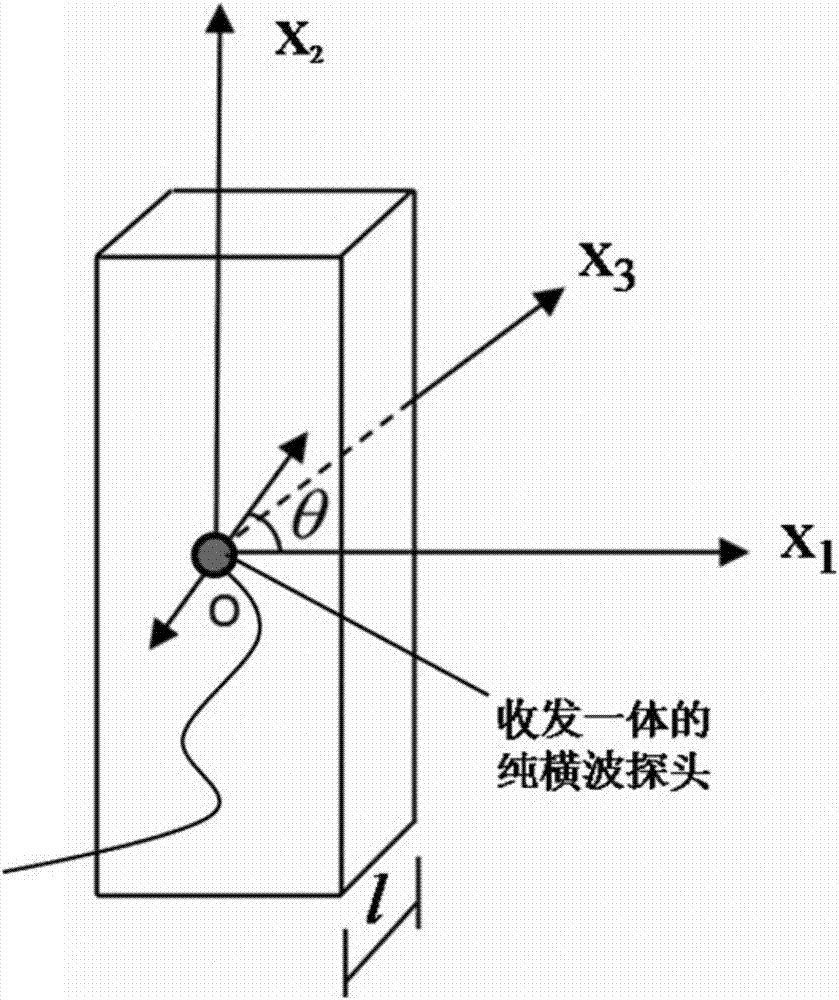

[0046] Such as image 3 Shown is a schematic diagram of the shear wave propagating in the steel member, where the contact point of the shear wave probe and the steel m...

Embodiment 2

[0098] Embodiment 2 The method for identifying the absolute stress of steel components based on shear wave spectrum analysis in the present invention is used for testing the absolute stress of steel components

[0099] In order to further verify the accuracy of the method of the present invention for detecting the absolute stress of steel components, the following tests and comparative tests for detecting the absolute stress of steel components were done.

[0100]No. 65 high-quality structural steel can not only be used in load-bearing components of building steel structures, but also widely used in mechanical welding and parts processing. Therefore, the study on the identification of absolute stress of steel members by using the spectrum analysis method with No. 65 high-quality structural steel as the object has reference significance for the study of welding residual stress detection and loading stress detection. A series of steel components were manufactured and processed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com