Parametric modeling production method for precast beam

A technology of parametric modeling and production methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as error-prone, heavy workload, and time-consuming, and achieve strong linkage and steel bar position correct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following example illustrates a parametric modeling production method for prefabricated beams, in which the parameters of the parametric model can be modified and adjusted according to the design, so as to facilitate the production of other prefabricated beams of the same type with various sizes.

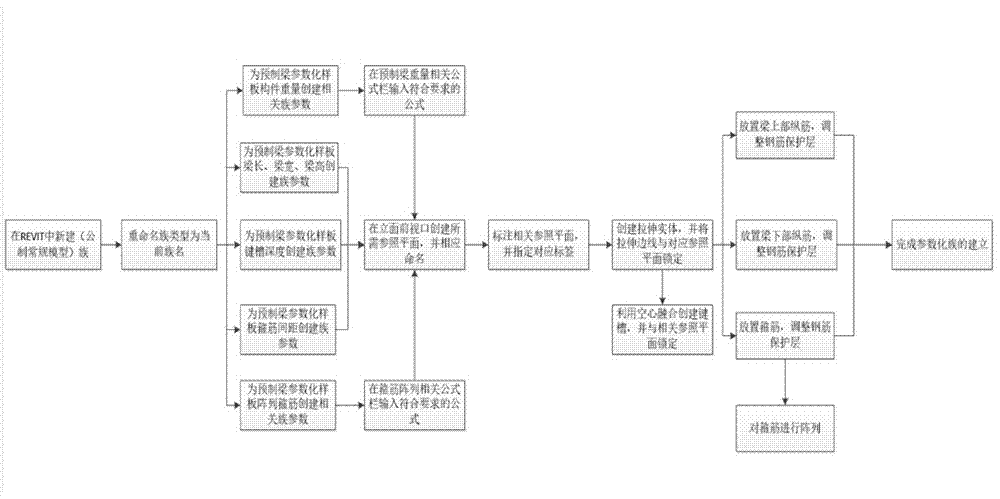

[0032] A parametric modeling production method of prefabricated beams, the process of which is as follows: firstly establish a parametric model of prefabricated beams, then produce construction drawings from the parametric models, and finally process prefabricated beams in factories according to the construction drawings.

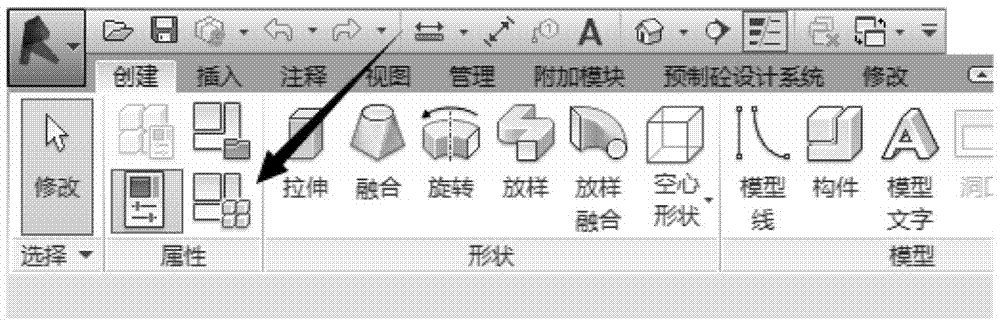

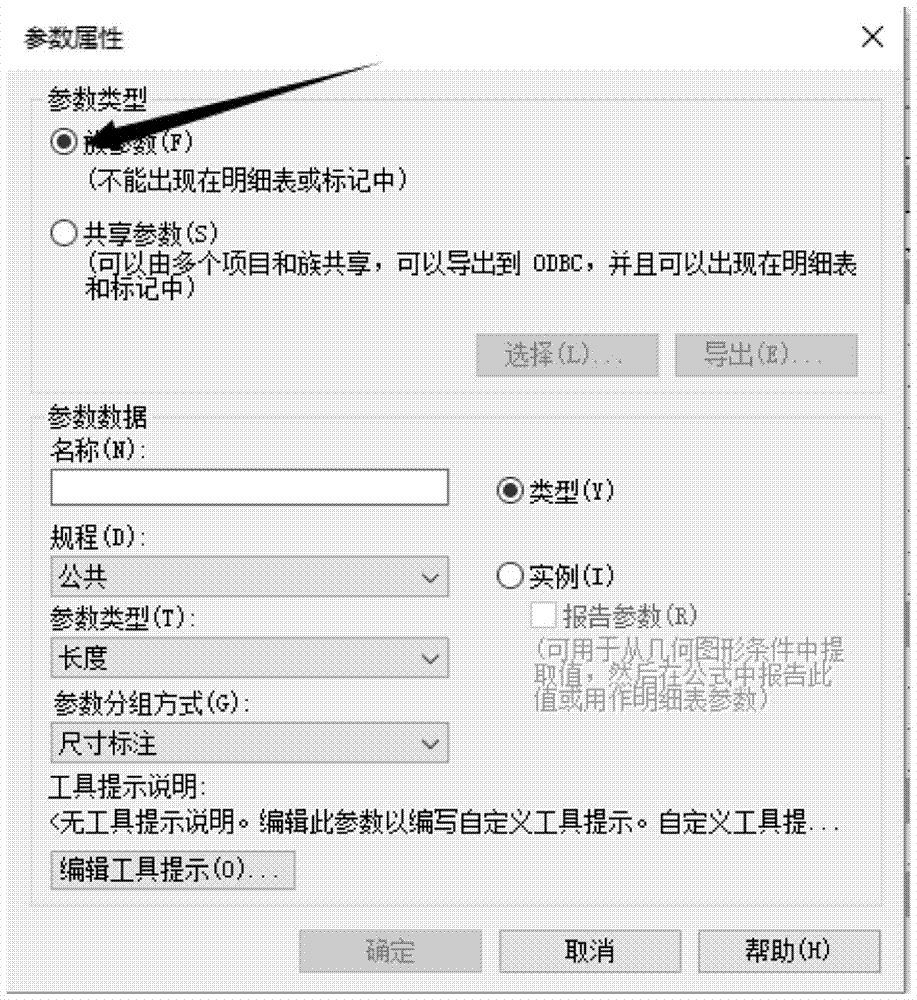

[0033] The parametric model of the prefabricated beam is driven by parameters, and the logical relationship driven by parameters: first set the family parameters (for the family parameter interface, see Figure 10 shown), that is, the driving parameters involved in the parametric driving. Then create a reference plane, label the reference plane, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com