The wire passing guide wheel of the stranding machine and the stranding machine

A technology of stranding machine and guide wheel, which is used in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of easy-running outer ring of bearings, deformation of finished wire rods, small R angle at the bottom of guide wheel grooves, etc. The effect of passing rate, prolonging service life and increasing product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

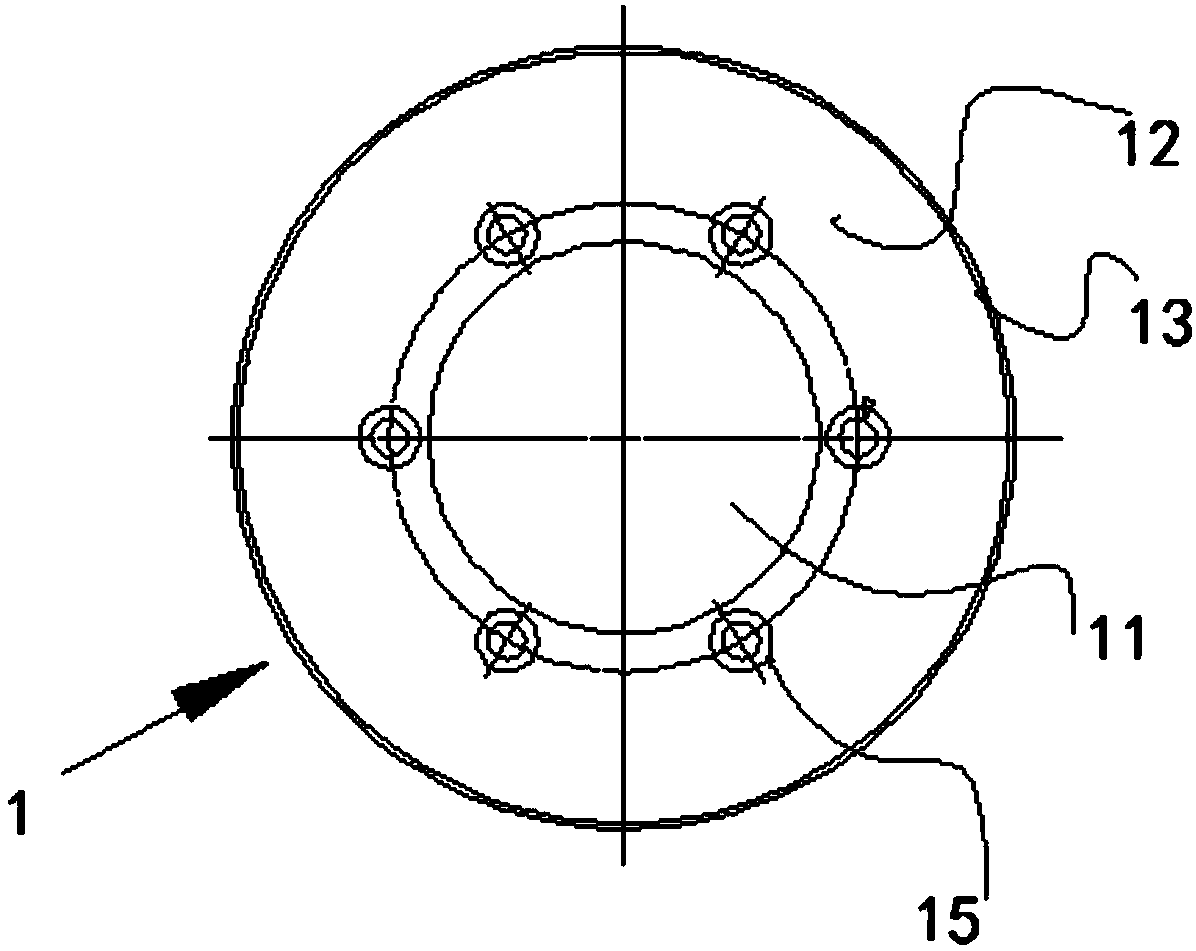

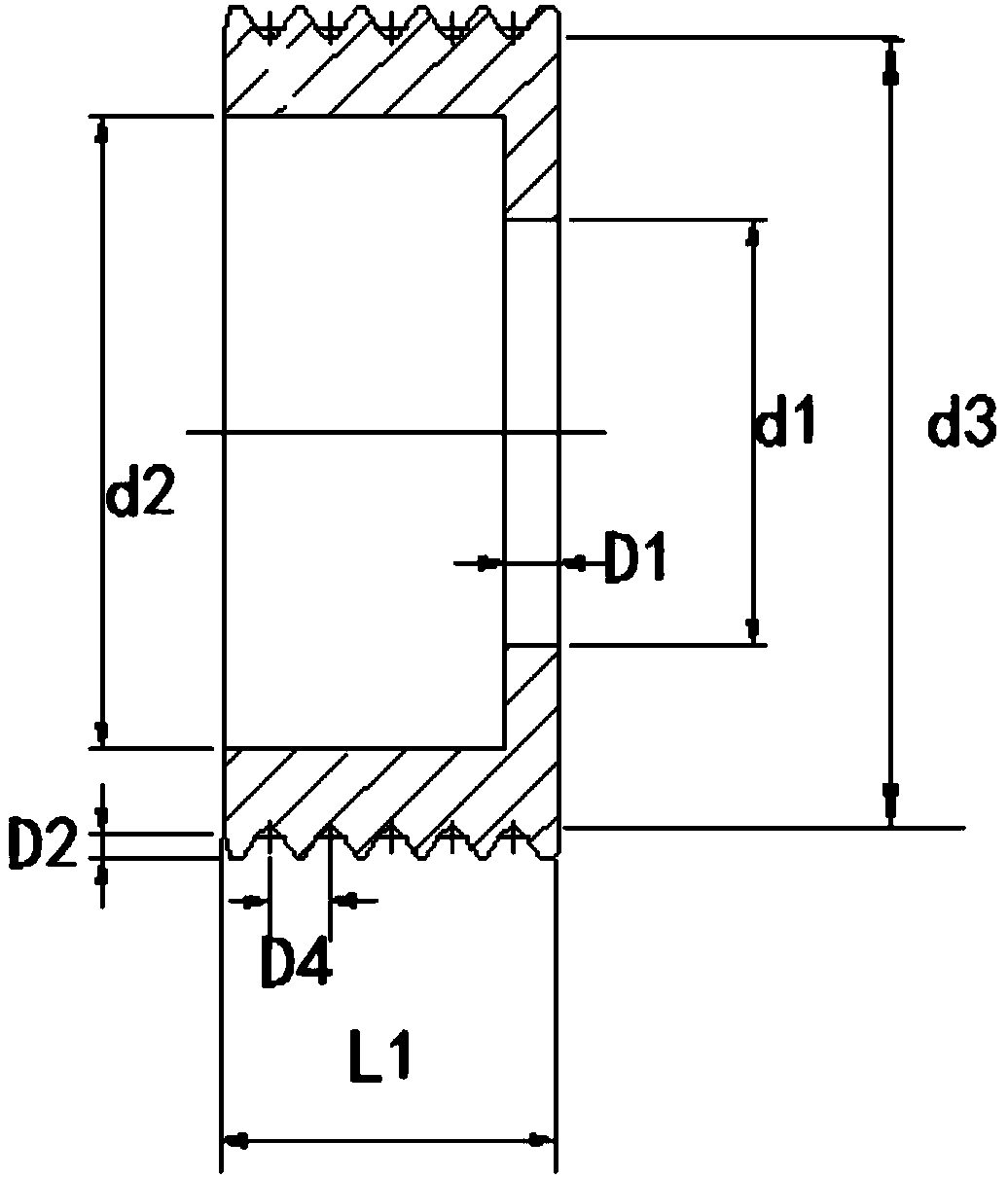

[0048] Embodiment 1: a kind of active drawing wheel, as Figure 2-Figure 3 As shown, one end of the rim is perpendicular to the wheel surface, and the side of the rim is flush with the wheel surface;

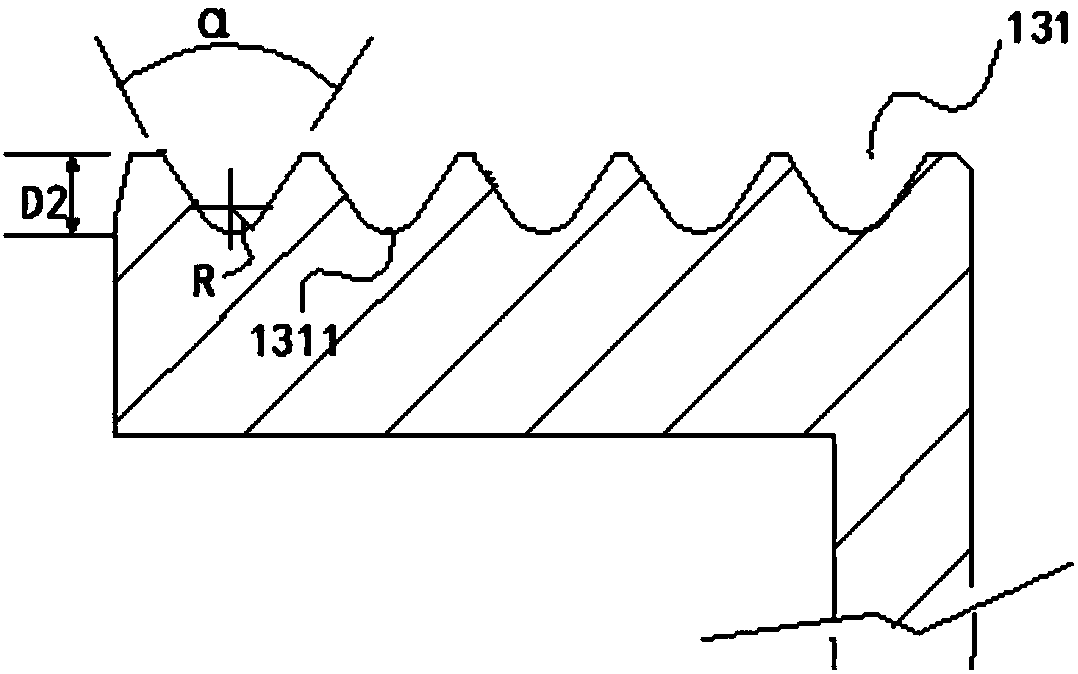

[0049] The surface of the rim is concavely formed with 5 V-shaped wire grooves, the bottom surface of the V-shaped wire grooves is an arc surface, the radius R of the arc surface is 3mm, and the included angle of the V-shaped wire grooves is 72.9 °;

[0050] The distance D4 between the centers of two adjacent V-shaped wire grooves is 10mm;

[0051] The thickness of the ceramic layer is 0.8mm;

[0052] The diameter d1 of the shaft-through hole is 70 mm, the width L1 of the rim is 55 mm, the thickness D1 of the wheel surface is 9 mm, the diameter d2 of the outer circumference of the wheel surface is 104 mm, and the groove of the wire groove The diameter d3 of the circle surrounded by the bottom is 130 mm, and the distance D2 between the top and the bottom of the V-shaped wire g...

Embodiment 2

[0053] Embodiment 2: 1. A wire arranging wire passing guide wheel, such as Figure 4 As shown, the outer circumference of the wheel surface is integrally connected with the wheel rim, and a fixed angle β is formed between the side surface of the wheel rim and the wheel surface, and the fixed angle is an obtuse angle;

[0054] The surface of the rim is concavely formed with a V-shaped wire groove, the bottom surface of the V-shaped wire groove is a plane, the width of the plane is 3mm, and the included angle of the V-shaped wire groove is 75°;

[0055] The distance D3 between the upper end of the groove wall of the V-shaped wire groove and the outer edge of the rim is 3 mm, and the thickness of the ceramic layer is 0.8 mm;

[0056] The inner circumference of the wheel surface is provided with a fastening ring 14 of a fixed shaft, the fastening ring is fixedly connected with the wheel surface, the width L2 of the fastening ring is 9mm, and the thickness D5 of the fastening ring ...

Embodiment 3

[0058] Embodiment 3, a kind of wire arrangement guide wheel, such as Figure 5 As shown, the outer circumference of the wheel surface is integrally connected with the rim, and an included angle is formed between the side surface of the rim and the wheel surface, and the included angle is an obtuse angle;

[0059] The surface of the rim is concave to form a V-shaped wire groove, the bottom surface of the V-shaped wire groove is an arc surface, the radius R of the arc surface is 3mm, and the included angle of the V-shaped wire groove is 47° ;

[0060] The distance D3 between the upper end of the groove wall of the V-shaped wire groove and the outer edge of the rim is 3 mm, and the thickness of the ceramic layer is 0.8 mm;

[0061] The thickness of the ceramic layer is 0.8mm;

[0062] The inner circumference of the wheel surface is provided with a fastening ring with a fixed shaft, the fastening ring is fixedly connected with the wheel surface, the width L2 of the fastening rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com