A half-chord plate steel for ultra-thick offshore petroleum machinery and its preparation method and application

A technology of offshore oil and half-chord plate type, which is applied in the direction of metal rolling, artificial islands, underwater structures, etc., and can solve problems such as the inability to apply half-chord plate steel production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

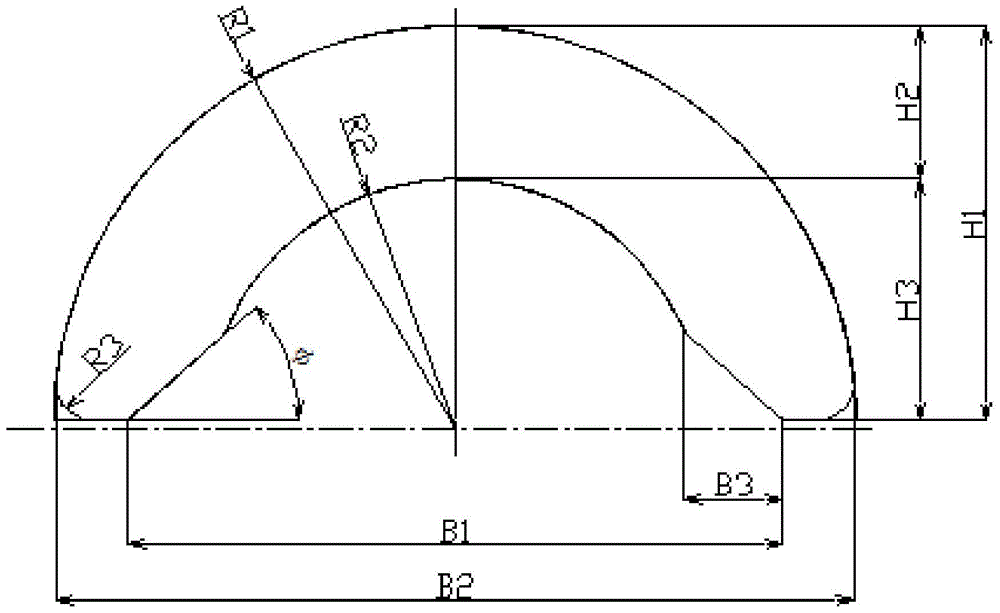

[0065] An ultra-thick semi-chord plate steel for offshore petroleum machinery, the structure is as follows figure 1 As shown, the longitudinal section of the half-chord shaped steel is arc-shaped as a whole and symmetrical with the center line as the axis. The upper surface of the half-chord shaped steel is R1 arc-shaped, and the lower surface of the half-chord shaped steel is R2 arc-shaped. The arc shape of R1 and the arc shape of R2 are concentric circles, the upper surface and the lower surface of the half-chord plate section steel are connected through the bottom side, and an inner groove is provided at the connection between the bottom surface and the bottom side of the half-chord plate section steel. The difference H2 between the arcs of R1 and R2 is 85mm, which is the thickness of the half-chord plate steel. The ultra-thick half-chord plate steel for offshore oil machinery should be suitable for the pile leg structure with a height of 400 feet.

[0066] The included ang...

Embodiment 2

[0077] With the ultra-thick semi-chord plate steel for offshore petroleum machinery described in Example 1, the difference is that

[0078] The difference H2 between the R1 arc shape and the R2 arc shape radius is 50 mm, which is the thickness of the half-chord plate steel. This ultra-thick half-chord plate steel for offshore oil machinery should be suitable for the pile leg structure with a height of 400 feet.

[0079] The included angle φ between the inner groove and the bottom side is 41.5°, and the width B3 of the inner groove is 2 / 5 of the thickness of the half-chord steel. The outer arc and the bottom side are connected by a smooth arc R3, and the vertical height between the lowest point and the highest point of the arc is 15mm.

Embodiment 3

[0081] With the ultra-thick semi-chord plate steel for offshore petroleum machinery described in Example 1, the difference is that

[0082] The difference H2 between the R1 arc shape and the R2 arc shape radius is 30mm, which is the thickness of the half-chord plate steel. This ultra-thick half-chord plate steel for offshore oil machinery should be suitable for the pile leg structure with a height of 300 feet.

[0083] The included angle φ between the inner bevel and the bottom side is 41°, and the width B3 of the inner bevel is 2 / 5 of the thickness of the half chord steel. The outer arc and the bottom side are connected by a smooth arc R3, and the vertical height between the lowest point and the highest point of the arc is 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com