Anchor chain system, with power buffer function, of single-point-anchoring net cage

An anchor chain and mooring technology, applied in the field of anchor chain system, can solve the problems of easy damage to the cage frame and anchoring foundation, and achieve the effects of cheap treatment measures, prevention of friction and mutual entanglement, and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

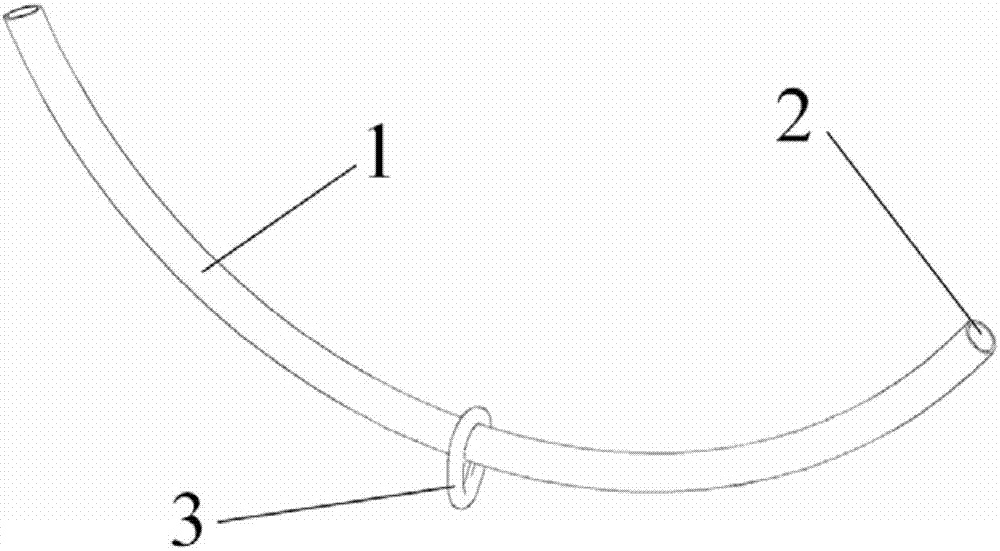

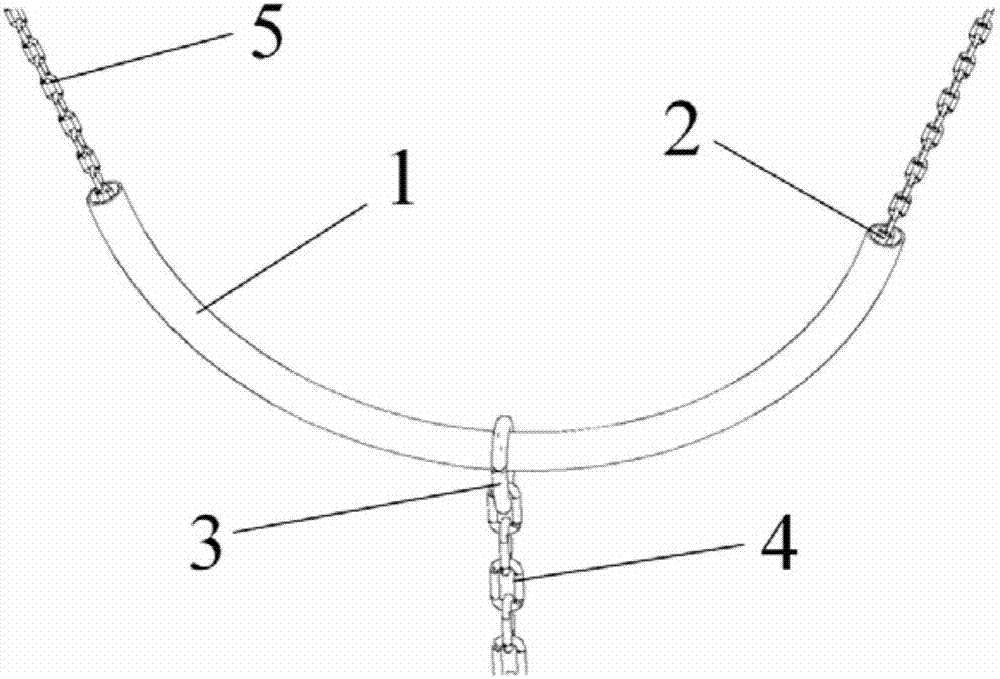

[0053] Embodiment 1: the situation of using the primary anchor chain 4 and the secondary anchor chain 5, such as Figure 5 shown. One end of the primary anchor chain 4 is moored on the mooring foundation 8, and the other end is fixedly moored on the mooring ring 3 of the elastic tube 1. The secondary anchor chain 5 passes through the tunnel 2 of the elastic tube 1, and after a plurality of casing pipes 7 are inserted on both sides, the two ends of the secondary anchor chain 5 are fixedly connected with the net cage floating pipe frame 11.

[0054] The resultant force on both sides of the secondary anchor chain 5 is equal to the pulling force of the primary anchor chain 4 , so the tensile force on the secondary anchor chain 5 is smaller than that of the primary anchor chain 4 . Through the mutual connection of the two-stage anchor chains, the stress concentration at the mooring point of the floating pipe frame 11 of the net cage is greatly reduced, and the safety of the floati...

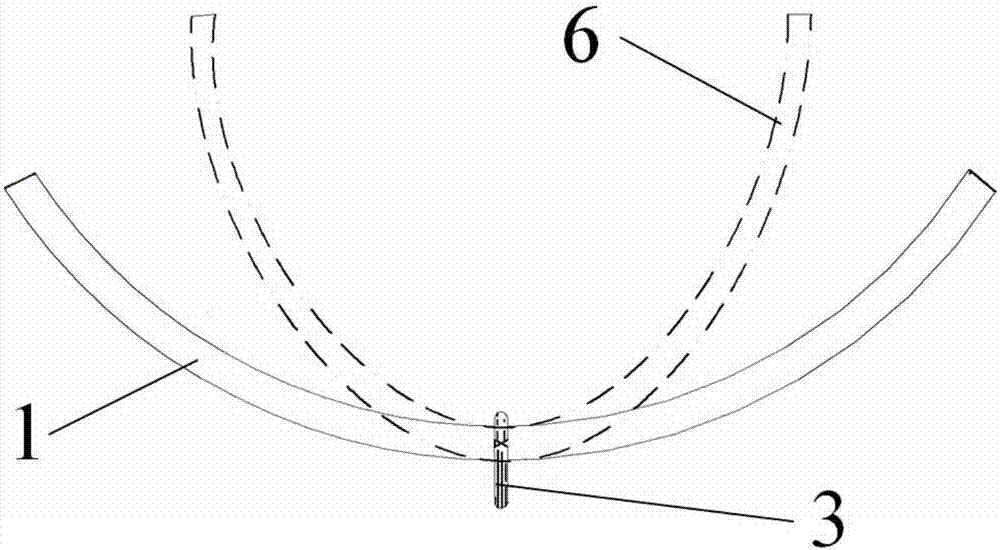

Embodiment 2

[0055] Embodiment 2: the situation of using the first-level anchor chain 4, the second-level anchor chain 5 and the third-level anchor chain 12, such as Figure 6 shown. The connection between the primary anchor chain 4 and the secondary anchor chain 5 is the same as that in Embodiment 1. The three-level anchor chain 12 passes through the tunnel 2 of the elastic tube 1 fixedly connected with the second-level anchor chain 5, and after a plurality of casing pipes 7 are inserted on both sides, the two ends of the three-level anchor chain 12 are connected to the cage floating pipe frame 11 Fixed connection.

[0056] In the present embodiment, there are 4 mooring points on the net cage floating pipe frame 11, and the load of the single-point mooring system is evenly distributed to these 4 mooring points, which obviously greatly reduces the stress concentration at the mooring point and improves The safety of net cage floating pipe framework 11 has been improved.

Embodiment 3

[0057] Embodiment 3: the situation of using the four-level anchor chain, such as Figure 7 shown. On the basis of embodiment 2, one more level of anchor chain is added, and the connection method is the same as above. In the present embodiment, there are 8 mooring points on the net cage floating pipe frame 11, and the load of the single-point mooring system is evenly distributed to these 8 mooring points, which greatly reduces the stress concentration at the mooring points and greatly reduces the stress concentration at the mooring points. Greatly improved the safety of net cage floating pipe frame 11.

[0058] Due to the sliding connection between the anchor chains of all levels and the elastic tube 1, the pulling force is evenly transmitted between the anchor chains of all levels, so that the pulling force suffered by the anchor chains of the same level is basically the same. As in this embodiment, the pulling forces on the two third-level anchor chains 12 are basically equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com