Production method and production device of microporous membrane coating filter material

A filter material and production device technology, applied in the direction of membrane filter, filtration separation, separation method, etc., can solve problems such as easy to be stained with dust, easy to fall off, unreliable, etc., and achieve a reasonable method, suitable for promotion, and a reasonable device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described

[0021] The embodiments are only some of the embodiments of the present invention, not all of them.

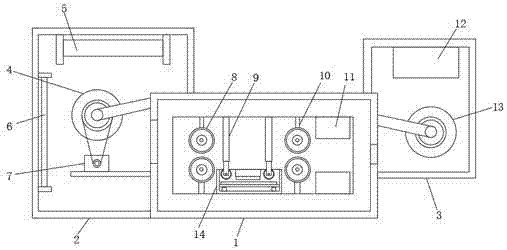

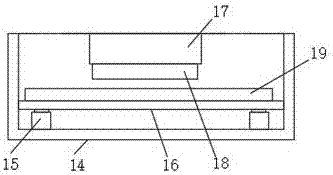

[0022] refer to Figure 1-2 , a production device for film-coated filter materials, comprising a first box 1, a second box 2 and a third box 3, one side of the first box 1 is fixed with a second box 2 by screws, the first The other side of the box body 1 is equipped with a third box body 3, and the middle position inside the first box body 1 is equipped with a film-covered pool 14. The inner bottom of the film-covered pool 14 is fixed with telescopic devices 15 on both sides, and the top of the telescopic device 15 A first support plate 16 is fixed, a first brush body 19 is fixed on the top of the first support plate 16, a second support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com