Rice crop primary processing device

A technology for processing devices and crops, applied in solid separation, sieves, grids, etc., can solve the problems of increasing costs, inability to remove dust efficiently, and low material classification, and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

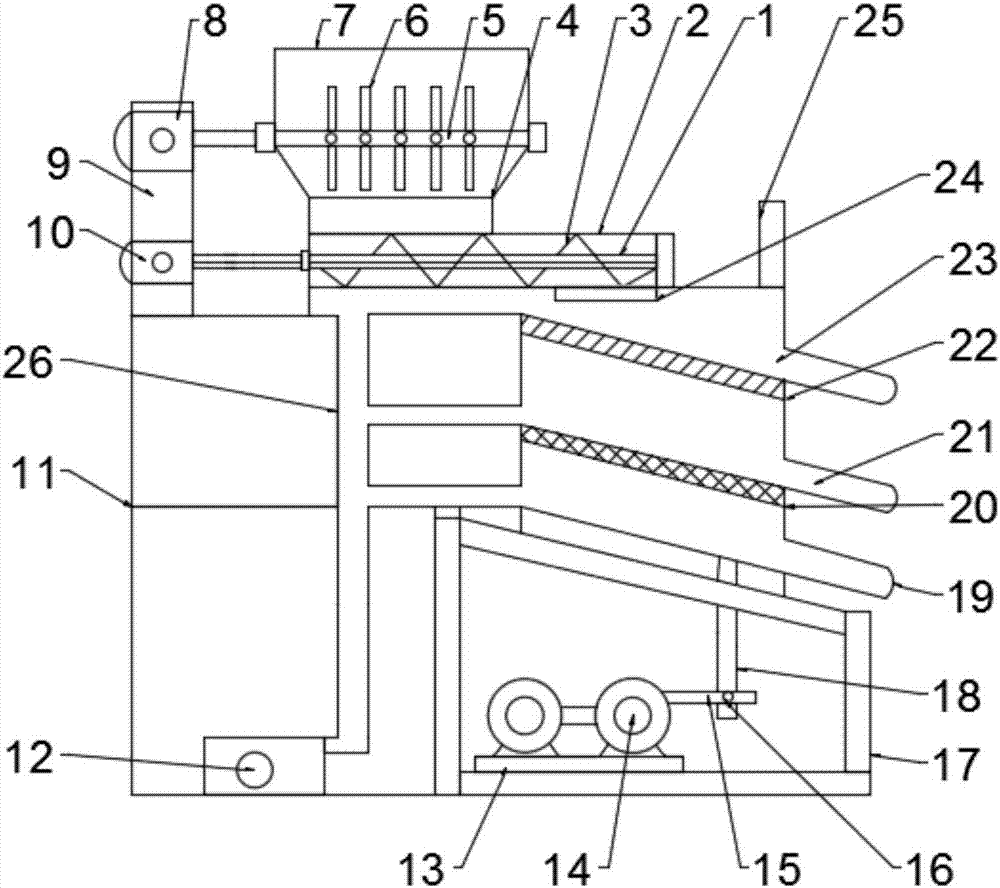

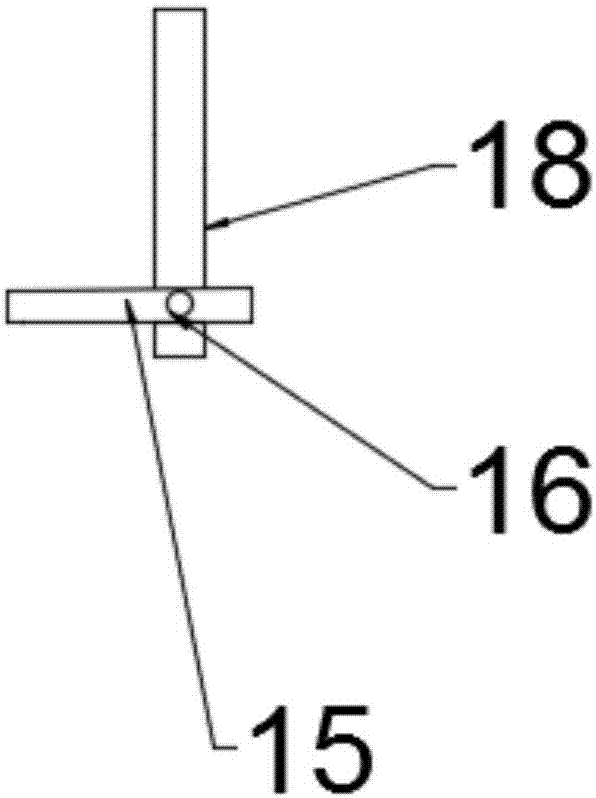

[0021] see Figure 1~3 , a primary processing device for rice crops, comprising a screening cabinet 11 installed on a frame 17, the screening cabinet 11 is fixed on the upper end of the frame 17, and the left middle part of the top of the screening cabinet 11 is provided with a feed inlet 24 , the feed port is docked with an auger feed mechanism; the right side of the feed port is provided with a blast pipe 25, and the blast pipe 25 is docked with an external blower; the inside of the screening cabinet 11 is installed at intervals from top to bottom Coarse screen 22 and fine screen 20, coarse screen 22 and fine screen 20 are all inclined design and its angle of inclination is between 10 °~35 °; In a kind of preferred embodiment of the present invention, this angle of inclination is 26°.

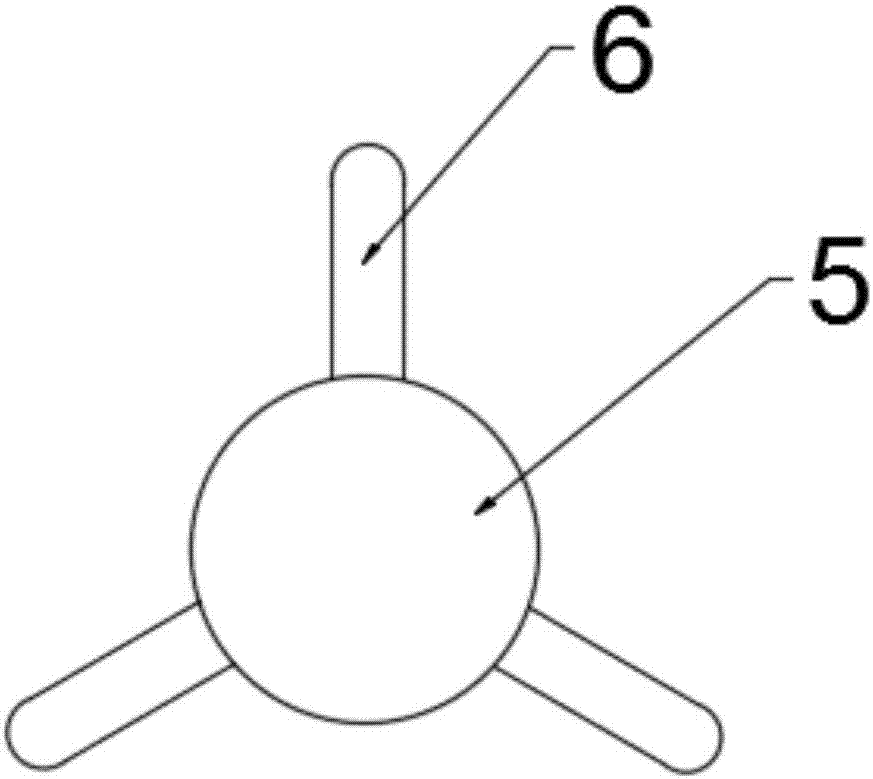

[0022] The auger feeding mechanism includes a conveying cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com