Integrated double-flange supporting device for rotating ultrasonic transducer

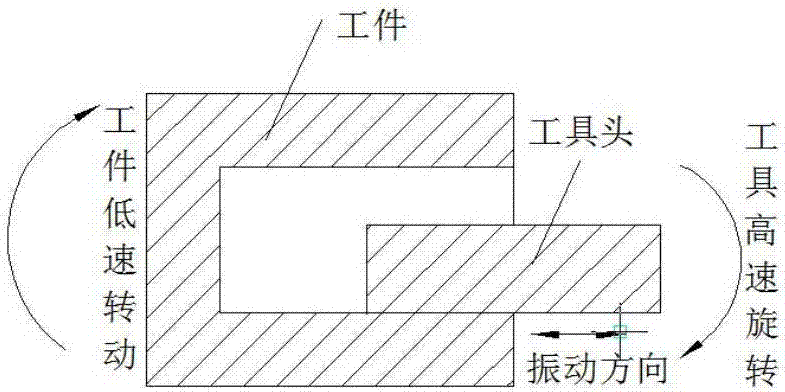

A technology of ultrasonic transducer and support device, which is applied in the directions of grinding machine parts, metal processing equipment, grinding/polishing equipment, etc., and can solve the problems of affecting machining accuracy and unfavorable high-speed rotation of ultrasonic transducers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

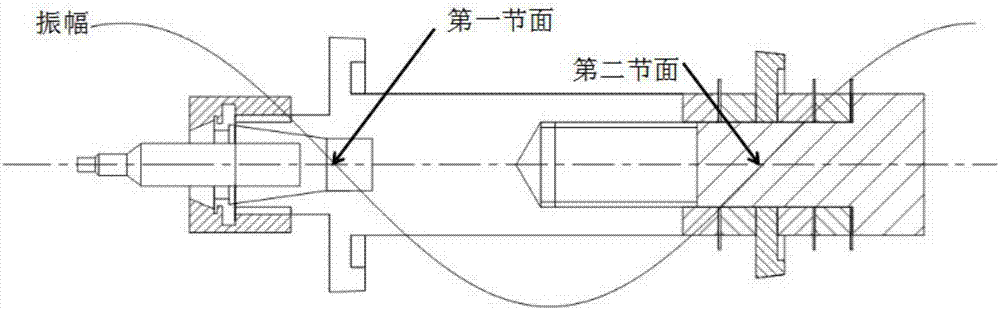

[0018] The invention relates to an integrated double-flange support device for a rotating ultrasonic transducer. It is part of the high-speed rotating ultrasonic grinding spindle. Under the support of two flanges, the ultrasonic transducer rotates stably at high speed (10000rpm) with the main shaft.

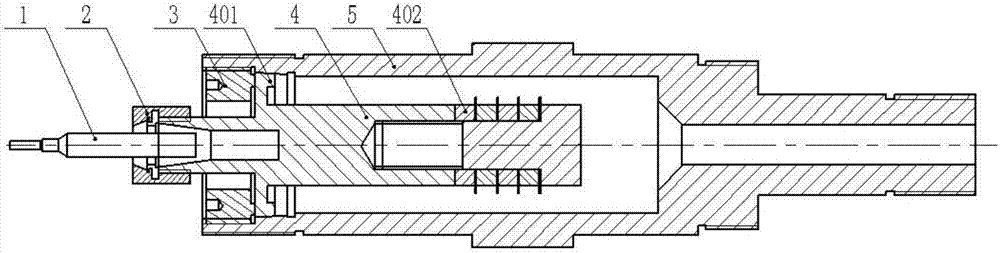

[0019] Figure 4 An integrated double-flange support device for a rotating ultrasonic transducer shown in , is characterized in that it includes an ultrasonic transducer (4) and two flanges, and the ultrasonic transducer (4) is transformed from a front cover plate Spindle rod (401), piezoelectric ceramic sheet (403), flange 2 (404), electrode sheet (405), rear cover (406), piezoelectric ceramic sheet (403), flange 2 (404), The electrode sheet (405) is located between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com