3D printer spray-head cleanliness detecting system

A cleanliness detection, 3D printer technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of using color to reduce 3D printing effect, affecting 3D printing effect, printing material residue, etc., to achieve High-quality nozzle cleanliness detection function, optimized printing effect and efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

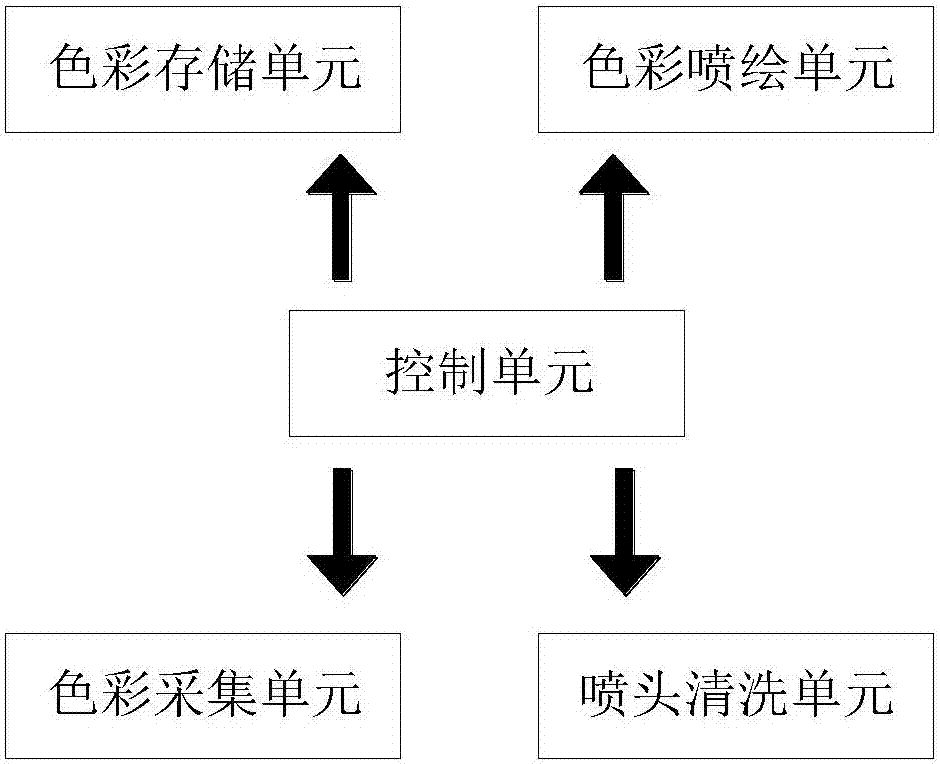

[0021] like figure 1 as shown, figure 1 A 3D printer nozzle cleanliness detection system proposed by the present invention.

[0022] refer to figure 1 , the 3D printer nozzle cleanliness detection system proposed by the present invention includes:

[0023] n storage tanks and n nozzles, and n storage tanks and n nozzles correspond one by one;

[0024] A color storage unit, configured to store the RGB values of the original colors of the printing materials in the n storage tanks;

[0025] The color inkjet unit is communicated with the control unit, and is used to extract the printing materials in the storage tank according to the instructions of the control unit and spray them out through the corresponding nozzles;

[0026] The color collection unit is used to collect the color image formed by the printing material ejected from the nozzle; Acquisition accuracy of color images.

[0027] The nozzle cleaning unit is communicated with the control unit and is used to clean t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com